What is Conductive Carbon Paste? - Nanografi

Conductive materials play a pivotal role in various industries, efficiently transferring electric currents and propelling advancements in fields like electronics and energy.

Carbon, notably in forms such as graphite and graphene, stands out for its exceptional electrical conductivity, opening avenues for innovations in electronics and sustainable energy solutions. Conductive carbon paste, a compound comprising carbon-based materials, offers versatility in applications ranging from electronics to energy storage. Key factors influencing its conductivity include temperature, material type, and electron concentration. This paste finds significant utility in areas like circuitry, solar cells, biomedical devices, and more. Nanografi's carbon paste products offer high electrical conductivity and versatility, meeting the needs of both the industry and your research.

Introduction

Conductive materials are substances that can efficiently conduct electric current. They are categorized into metals, semiconductors, and conductive polymers. These materials possess properties like electrical and thermal conductivity, ductility, and corrosion resistance. They are vital in applications such as electronics, electrical wiring, energy generation and transmission, consumer electronics, and medical devices. Recent advancements include materials like graphene, which has exceptional electrical conductivity. Challenges include cost, resource availability, and environmental concerns. Conductive materials are fundamental to modern technology and industry, continuously driving innovation in various fields.

Historical Development and Milestones of Conductive Materials

The historical development of conductive materials is closely intertwined with the progress of electronics and electrical engineering. Key milestones include the discovery of electricity, the identification of conductive materials like copper and silver, and the invention of the transistor and integrated circuits, which revolutionized electronics. Discoveries in semiconductors, superconductivity, and the isolation of materials like carbon nanotubes and graphene have expanded the possibilities for highly conductive materials with remarkable properties. These materials play a vital role in diverse applications, from telegraph systems and early computers to modern nanoelectronics and emerging fields like quantum computing, shaping the course of technology and industry.

Conductive Carbon Paste: An Overview

A conductive carbon paste is a mixture or compound consisting of carbon-based materials that can conduct electricity. It is often used as an electrical conductor or electrode material in various applications, including electronics, sensors, batteries, and electrochemical devices.

The key components of conductive carbon paste include:

Carbon Material: Carbon-based materials like carbon black, graphite, nanotubes, or graphene, which provide electrical conductivity.

Binder: Polymers such as polyvinylidene fluoride (PVDF) or ethyl cellulose, which hold the carbon particles together and adhere them to substrates.

Solvent: Substances like N-methyl-2-pyrrolidone (NMP), acetone, or isopropanol that dissolve or disperse carbon and binder to create a workable paste.

Additives: Various functional agents, like thickeners, dispersants, and surfactants, to enhance performance, stability, or adhesion.

Conductivity Enhancers: Materials like metal nanoparticles (e.g., silver nanoparticles) may be added to boost electrical conductivity.

Substrate:The surface or material on which the paste is applied, such as a circuit board or electrode.

Mixing and Processing Equipment: Equipment like mixers and homogenizers used to ensure a uniform mixture.

Carbon is important in conductivity due to its diverse forms, such as graphite and graphene, which exhibit exceptional electrical conductivity. These carbon structures enable applications in electronics, batteries, and even emerging technologies like flexible and transparent electronics. Carbon's conductivity plays a pivotal role in advancing modern technology and sustainable energy solutions.

How is Carbon Paste Produced?

Raw Materials

Conductive carbon paste consists of carbon-based materials (e.g., carbon black, graphite), a binder (e.g., PVDF, ethyl cellulose), a solvent (e.g., NMP, acetone), additives, and, optionally, conductivity enhancers like silver nanoparticles. These components are mixed to create a paste with tailored electrical conductivity and adhesion properties for various applications.

Production Processes

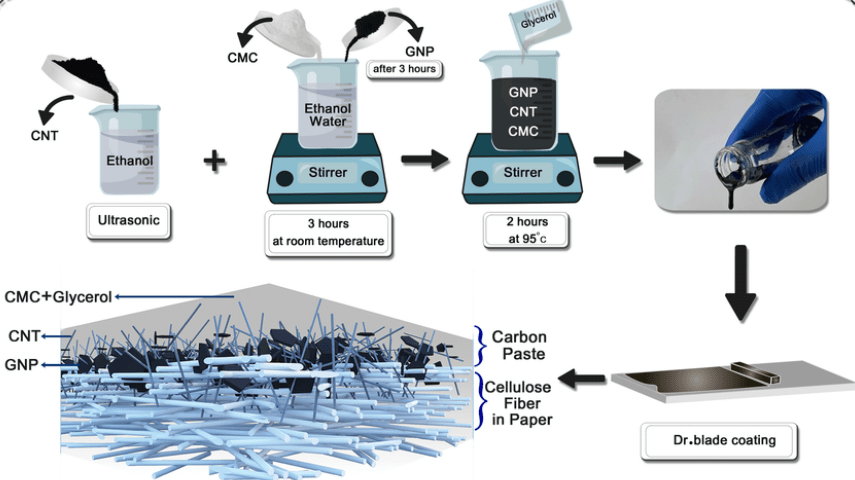

The production process of conductive carbon paste, also known as carbon assembly paste, involves selecting raw materials like carbon-based materials, binders, solvents, additives, and, optionally, conductivity enhancers. These materials are precisely weighed, mixed, and homogenized to create a consistent paste with tailored electrical conductivity and adhesion properties. Quality control tests are performed, and the final product is filled into containers and stored until it's ready for application, typically on substrates like printed circuit boards or electrodes. The specific process may vary depending on the formulation and intended use of the paste.

Figure 1. Preparation process of carbon paste films using the doctor blade method.

Factors Influencing Conductivity:

Electrical conductivity is influenced by various factors, and understanding these factors is crucial for designing and utilizing conductive materials effectively. Some of the key factors influencing electrical conductivity include:

Temperature: Electrical conductivity in most materials tends to increase with temperature. This is because higher temperatures provide more energy to electrons, allowing them to move more freely and conduct electricity more effectively. However, this relationship may not hold for all materials, especially semiconductors.

Material Types: Different materials exhibit varying levels of electrical conductivity. Metals, such as copper and silver, are excellent conductors due to their abundance of free electrons. Semiconductors like silicon have intermediate conductivity, and insulators like rubber have very low conductivity.

Electron Concentration: The number of free electrons available for conduction significantly affects conductivity. In metals, a high concentration of free electrons contributes to high conductivity. Doping, a process of intentionally introducing impurities into a semiconductor

How to Use Carbon Paste?

Ensure Safety: Always read the product label and safety data sheet (SDS) before use. Wear appropriate personal protective equipment (PPE) such as gloves and eye protection.

Prepare the Surface: The surface where you want to apply the carbon paste should be clean and free of any contaminants. Clean the surface with a suitable solvent, such as isopropanol, and allow it to dry.

Application:

For electrochemical experiments, you might need to apply the paste to an electrode surface to enhance conductivity. You can use a spatula or a similar tool to spread the paste evenly.

In electronics, carbon paste can be used to bridge gaps in circuits or to make conductive connections. Use a toothpick or a small brush to apply the paste to the desired area.

Some therapeutic devices use carbon paste to enhance electrical contact between an electrode and the skin. Apply the paste to the electrode surface, ensuring an even spread.

Setting/Curing: Some carbon pastes may require time to set or cure, so it's essential to let the paste sit undisturbed for the recommended time.

Testing: Once the paste has set or cured (if required), you can test its conductivity using a multimeter or another appropriate instrument.

Clean Up: After application, clean up any excess paste with a solvent or as recommended by the manufacturer. Store the carbon paste container in a cool, dry place and ensure it's tightly sealed to prevent drying out.

Storage: It's crucial to store carbon paste in a cool, dry place and keep the container tightly closed to maintain its consistency and performance.

Disposal: Dispose of the carbon paste as per the local regulations and recommendations mentioned in its SDS.

What are the Applications of Carbon Paste?

Electronics and Circuitry

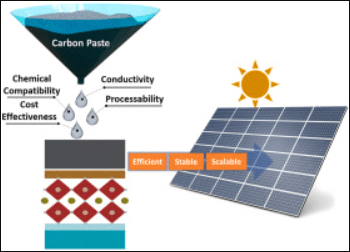

Conductive carbon paste is a versatile material widely used in electronics and circuitry applications due to its ability to provide electrical conductivity and adhere to various substrates. It finds use in applications such as printed circuit boards (PCBs), flexible electronics, membrane switches, sensors, electrodes, solar cells, batteries, thermistors, heating elements, electromagnetic shielding, and repair/rework in the electronics industry. Its adaptability and reliability make it a valuable component for creating functional electronic devices and components.

Solar Cells

Figure 2. Carbon pastes for carbon electrode-based perovskite solar cells.

Biomedical Devices

Other Emerging Applications

Technological advancements are one of the primary factors rapidly shaping today's world. Carbon paste, with its conductivity properties and extensive surface area, has the potential to be used in critical technological applications such as energy storage and transmission. Particularly in the field of renewable energy storage technologies, where the need for energy storage is increasing alongside the growth of energy sources, carbon paste could have the potential to be used as an electrode material in energy storage systems like supercapacitors.

Furthermore, in this era where Edge Computing has gained importance for real-time data transmission and processing in IoT (Internet of Things) devices, the high conductivity of carbon paste can contribute to the development of energy-efficient transmission and storage solutions in these devices. In a time when technological advancements continue, and new materials constantly emerge, the potential of materials like carbon paste can create opportunities for various technological applications.

Comparison with Silver Pastes

Conductive carbon paste and silver paste are materials used for electrical conductivity in various applications. Key differences include:

-Raw Material: Carbon-based materials in carbon paste vs. silver in silver paste.

-Cost: Carbon paste is generally more cost-effective.

-Conductivity: Silver paste offers superior electrical conductivity.

-Applications: Carbon paste suits a wide range of applications, while silver paste is used where high conductivity is critical.

-Environmental Impact: Carbon paste is often considered more environmentally friendly.

-Adhesion and Compatibility: Both vary depending on the formulation.

-Resistivity and Heat Resistance: Silver paste typically has lower resistivity and better heat resistance.

The choice depends on the specific application's requirements, cost considerations, and environmental factors.

Recent Advancements and Future Prospects

Innovations in carbon paste formulation have led to significant advancements in its performance and versatility. Key innovations include the incorporation of graphene and carbon nanotubes for enhanced conductivity, the development of sustainable binders, flexible and stretchable formulations for wearable tech, and printable variants for rapid fabrication. High-temperature pastes, bio-compatible options, and improved adhesion promoters cater to specialized applications. Additionally, self-healing properties and customizable formulations expand the range of potential uses. These innovations make carbon paste a valuable material in various industries, from electronics to medical devices and renewable energy.

Potential Areas of Growth

The field of carbon paste and its applications holds significant potential for growth and innovation. Key areas of growth include:

-Renewable Energy: Enhancing efficiency and durability of solar cells and batteries.

-Wearable Technology: Developing advanced wearables for healthcare and fitness tracking.

-Electric Vehicles (EVs): Improving batteries, charging systems, and EV components.

-Medical Devices: Expanding applications in biocompatible devices and biosensors.

-Internet of Things (IoT): Supporting diverse IoT applications with conductive components.

-Flexible Electronics: Enabling flexible displays and sensors.

-Environmental Technologies: Contributing to carbon capture and storage.

-Additive Manufacturing: Creating customized conductive parts via 3D printing.

-Aerospace and Defense: Use in aerospace components and radar systems.

-Smart Packaging: Incorporating sensors into packaging for monitoring.

-Advanced Electronics: Playing a role in emerging technologies like quantum computing.

-Energy Storage and Grid Management: Supporting renewable energy integration and grid management.

Carbon paste's versatility and adaptability make it a promising material for addressing evolving industry demands and technological advancements across various sectors.

Conclusion

Conductive carbon paste is a versatile material with a wide range of applications across industries. It provides electrical conductivity and adheres to substrates, making it valuable for electronic components, sensors, renewable energy systems, medical devices, and more. Recent innovations include the use of advanced carbon nanomaterials and sustainable formulations. Carbon paste is considered environmentally friendly and offers growth potential in renewable energy, wearable tech, EVs, IoT, and other emerging areas. Its customizability and adaptability make it a crucial material in modern technology and sustainability efforts.

Discover the potential of carbon paste with Nanografi to enhance efficiency and innovation in your projects and research.

References

Carbon paste electrode - Wikipedia. (n.d.). Retrieved March 14, 2024, from https://en.wikipedia.org/wiki/Carbon_paste_electrode

Integrated Product and Process Model for Production System Design and Quality Assurance for EV Battery Cells | Semantic Scholar. (n.d.). Retrieved March 14, 2024, from https://www.semanticscholar.org/paper/Integrated-Product-and-Process-Model-for-Production-Reinhart-Kurfer/1dc86e8bb9f7482f2134829ccc3a6072676ef4e0

Nanostructured Solar Cells - Nanografi Nano Technology. (n.d.). Retrieved March 14, 2024, from https://nanografi.com/blog/nanostructured-solar-cells/

Preparation process of carbon paste films using the doctor blade method | Download Scientific Diagram. (n.d.). Retrieved March 14, 2024, from https://www.researchgate.net/figure/Preparation-process-of-carbon-paste-films-using-the-doctor-blade-method_fig1_366517025

Yu, Y., Hoang, M. T., Yang, Y., & Wang, H. (2023). Critical assessment of carbon pastes for carbon electrode-based perovskite solar cells. Carbon, 205, 270–293. https://doi.org/10.1016/j.carbon.2023.01.046

Recent Posts

-

Advanced Materials for Unmanned Aerial Vehicle (UAV) Protection Against Laser

Consider a UAV on a critical mission, rendered inoperative by a sudden laser attack. With the increa …26th Jul 2024 -

Simulation and Modeling of Material Properties

Our world is composed of a dazzling array of materials, each with its own unique properties that dic …19th Jul 2024 -

Advanced Coatings for Superior Corrosion and Wear Resistance

Corrosion and wear pose significant challenges across various industries, leading to substantial eco …12th Jul 2024