3D Printer Materials

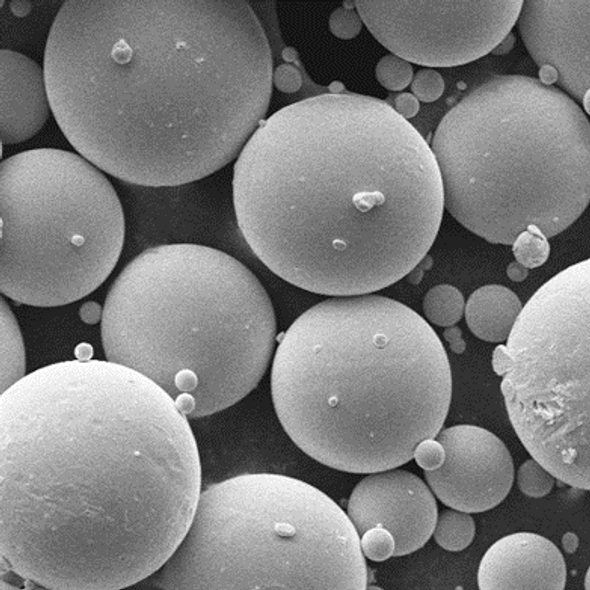

Nanografi offers high-quality nickel and titanium powders with exceptional properties in terms of 3D Printer Materials.

Nickel powder exhibits excellent corrosion resistance, oxidation resistance, and heat resistance, making it suitable for various applications. Titanium powder is ideal for 3D printing in industries like medical, aerospace, and tooling. Our powders are lightweight, strong, and corrosion resistant, meeting the demands of today's markets. Choose Nanografi for superior quality nickel and titanium powders for 3D printing, delivering exceptional performance for your projects and business.

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

Spherical Nickel Base Alloy Micron Powder, Inconel 718 Powder, Size: 15-45 µm

€45.0025 grams/45 € 100 grams/85 € 500...NG09PM0118€45.00 -

Spherical Nickel Base Alloy Micron Powder, Inconel 718 Powder, Size: 10-25 µm

€43.0025 grams/ 43 € 100 grams/82 € 500...NG09PM0117€43.00 -

Spherical TC4 Titanium Based Micron Powder for 3d Printers, Ti6Al4V, 50-150 µm, Spherical

€62.0025 grams/62 € 100 grams/123 € 500...NG09PM0112€62.00 -

Spherical Nickel Base Alloy Micron Powder, Inconel 718 Powder, Size: 50-150 µm

€38.0025 grams/ 38 € 100 grams/73 € 500...NG09PM0120€38.00 -

Spherical Nickel Base Alloy Micron Powder, Inconel 718 Powder, Size: 30-60 µm

€43.0025 grams/ 43 € 100 grams/82 € 500...NG09PM0119€43.00 -

Spherical Nickel Base Alloy Micron Powder, Inconel 625 Powder, Size: 50-150 µm

€38.0025 grams/ 38 € 100 grams/73 € 500...NG09PM0116€38.00 -

Spherical Nickel Base Alloy Micron Powder, Inconel 625 Powder, Size: 30-60 µm

€42.0025 grams/ 42 € 100 grams/80 € 500...NG09PM0115€42.00 -

Spherical Nickel Base Alloy Micron Powder, Inconel 625 Powder, Size: 15-45 µm

€44.0025 grams/ 44 € 100 grams/85 € 500...NG09PM0114€44.00 -

Spherical Nickel Base Alloy Micron Powder, Inconel 625 Powder, Size: 10-25 µm

€62.0025 grams/62 €100 grams/107 €500 grams/298 €1000 grams/435 €5000 grams/1850 € Please contact us for quotes for larger quantities Spherical Nickel Base Alloy Micron Powder Inconel 625 Powder, Size:...NG09PM0113€62.00 -

Spherical TC4 Titanium Based Micron Powder for 3d Printers, Ti6Al4V, 25-50 µm, Spherical

€68.0025 grams/68 € 100 grams/135 € 500...NG09PM0111€68.00 -

Spherical TC4 Titanium Based Micron Powder for 3d Printers, Ti6Al4V, 15-35 µm, Spherical

€74.0025 grams/74 € 100 grams/149 € 500...NG09PM0110€74.00 -

Spherical TC4 Titanium Based Micron Powder for 3d Printers, Ti6Al4V, 10-25 µm, Spherical

€82.0025 grams/82 € 100 grams/159 € 500...NG09PM0109€82.00 -

Titanium Alloy Micron Powders, CPTi, 50-150 µm, Spherical

€80.0025 grams/80 € 100 grams/168 € 500...NG09PM0108€80.00 -

Titanium Alloy Micron Powders, CPTi, 25-50 µm, Spherical

€83.0025 grams/83 € 100 grams/175 € 500...NG09PM0107€83.00 -

Titanium Alloy Micron Powders, CPTi, 15-35 µm, Spherical

€85.0025 grams/85 € 100 grams/180 € 500...NG09PM0106€85.00 -

Titanium Alloy Micron Powders, CPTi, 10-25 µm, Spherical

€95.0025 grams/95 € 100 grams/205 € 500...NG09PM0105€95.00