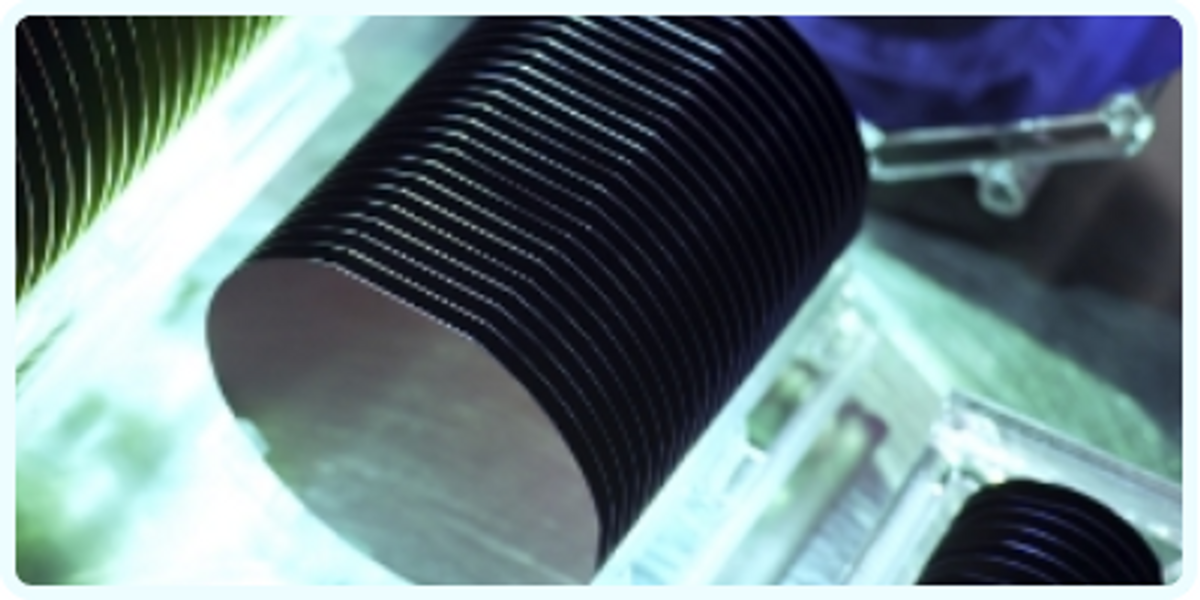

Indium Phosphide Wafers

Indium phosphide (InP) wafer is a semiconductor material consisting of phosphorus and indium. It has a cubic crystalline assembly centered on the face, alike to GaAs and most of the semiconductors. Indium phosphide (InP) wafer is manufactured with the help of indium iodide and white phosphorus at the temperature of 400 °C. In addition, it can also be manufactured by integrating the clean components at high pressure and high temperature. Indium phosphide (InP) wafer has many useful applications, maximum in the electronic industry as it is used to manufacture high power and high-frequency electronics. It has applications in other sectors as well. This article will study the properties, production, and applications of Indium phosphide (InP) wafer.

Importance of Indium phosphide (InP) wafer

It is a vital semiconductor component having high limit drift electronic speed, good thermal conductivity, and good radiation resistance. It is perfect for high speed, high frequency, and high-power electronic devices and chips. It is commonly used for manufacturing microwave communication, solid-state lighting, fiber optic communication, satellite, orientation/navigation, solar cells, and other sectors of military and civil applications.

Properties of Indium phosphide (InP) wafer

The relatively recent development of advanced techniques for the growth of indium phosphide monocrystals has shown in recent years that this material is very interesting for the realization of a very wide range of high-performance electronic devices. When noticing the electrical characteristics of the Indium phosphide (InP) wafer, it has so far received the most attention. The most important properties include:

1. higher speed of electron saturation,

2. higher thermal conductivity,

3. higher resistance to breakdown of ionization coefficients of the highest threshold voltage,

4. high resistance to radiation, and prolonged exposure to radiation of semiconductor material commonly present in outer space, especially at the microwave frequency.

It can significantly alter the characteristics and therefore the functionality.

The possibility of finely controlling the doping effect in the indium phosphide wafer through ion implantation has allowed the realization of a large number of devices. The small value of the height of the Schottky barrier between doped InP and most metals makes it almost possible to build MESFET circuits (Metal-Semiconductor Field-Effect Transistor). In addition, it can also produce JFET (Junction Field-Effect Transistor) and MISFET (Metal Insulator Semiconductor Field-Effect Transistor) circuits.

Indium phosphide also has one of the longest-lived optical phonons of any compound with the zincblende crystal structure.

Production of Indium Phosphide (InP) Wafers

Indium phosphide (InP) wafer are manufactured by the reaction of indium iodide and white phosphorus at the temperature of 400 °C. In addition, it can also be manufactured by integrating the clean components at high pressure and high temperature. Another interesting method to manufacture Indium Phosphide (InP) wafer is through the thermal decomposition of trialkyl indium and phosphine compound. A multi-stage process is employed in the manufacturing of Indium Phosphide (InP) wafer to ensure the highest quality product.

By gradually varying the percentage of the ternary compounds, we can achieve a series of InP semiconductor with crystallographic characteristics and structure to desired energy bands, also making possible the realization of heterojunctions between materials with similar reticular step (thus avoiding the creation of mechanical stresses on the separation surface).

Five Applications of Indium Phosphide (InP) Wafers

Indium phosphide (InP) wafer have applications in different sectors, but the main applications are found in the electronics industry.

1. Indium Phosphide (InP) Wafers’ Electronics Applications

Indium phosphide (InP) wafer is being studied since the year 1980 and the successful experiments on this compound have allowed us to benefit from its innovative uses in the electronics sector. Currently, it is being employed in lasers, photo-detectors, fiber communications components, LEDs, semiconductor optical amplifiers and modulators.

The uses of this material spread across a communications network, nominating it the starting point integration of passive equipment in the whole chip system. It allows complete integrated functionality which involves light detection, generation, amplification, passive splitting, routing, and combining as well as high-speed switching and modulation. Indium phosphide (InP) wafer can be employed to generate high-speed switches, modulators, detectors, amplifiers or passive waveguides for connecting these electronic devices.

Indium phosphide (InP) wafer are mainly employed to produce high-power and high-frequency electronics. It has high-quality electron velocity, due to which, it is used to manufacture optoelectronic devices, resonance tunneling diodes, and rapid transistors.

Moreover, the InP wafer is very useful in the construction of the latest generation active devices, such as doping heterojunction FETs, resonant tunneling FETs, and super-lattice devices. To these must be added the optical devices: detectors (diodes PTN and APD) and sources (LED, laser in heterojunction and quantum wells); the advantage is that optical devices can be integrated with signal processing devices on the same substrate. Moreover, it has an interesting application in solar cells. Indium phosphide wafer is indeed suitable for this purpose because of its already cited characteristics of resistance to cosmic radiation. In many of the aforementioned devices, ternary compounds such as As and Ga are generally used, reserving the role of the semi-insulating substrate for the InP. A variety of its uses justifies the efforts made to improve the quality of the crystalline indium phosphide wafer.

Moreover, the pseudomorphic rupture disc heterojunction bipolar transistor can be made with the help of Indium phosphide (InP) wafer and indium gallium arsenide and this device functions at 604 GHz.

Indium phosphide (InP) wafer due to its semiconductor properties, is also used to obtain some types of diodes including laser and LED diodes. The direct bandgap of Indium phosphide (InP) wafer makes it fruitful for manufacturing optoelectronic devices such as laser diodes. Some industries use Indium phosphide (InP) wafer as the chief material for producing photonic integrated circuits for the purpose of optical industry telecommunications.

In addition, Indium phosphide (InP) wafer can be used as a substrate for epitaxial indium gallium arsenide optoelectronic equipment.

2. Indium Phosphide (InP) Wafers in Hybrid Silicon Lasers

Indium phosphide (InP) wafer have an important use in Hybrid Silicon Lasers. It is currently used in the photonics sector. A few of the silicon hybrids are Gallium Arsenide, Elementary Semiconductors, Indium Phosphide, Polymers, Silica, and many more!

Prior to the discovery of Indium phosphide (InP) wafer, the only option was to use Silicon, which is not only expensive but also difficult to work with. This is the reason that forced the Researches and Scientists to look for an alternative material to manufacture laser integrated circuits at low expense and greater efficiency to ultimately produce hybrid silicon lasers.

3. Indium Phosphide (InP) Wafers’ Medical Field Applications

In the medical sector, Indium phosphide (InP) wafer is commonly used to produce optoelectronic equipment due to its greater area. Indium phosphide (InP) wafer find its use not only for controlling equipment in Surgery but also to monitor important signs.

4. Indium Phosphide (InP) Wafers’ Fast Heterostructure Appliance

Indium phosphide (InP) wafer possess the capacity to work flawlessly at a greater peak-to-peak ratio from greater thermal conductivity. It is also best to manufacture optical fibers with least diffusion and loss.

5. InP-based Heterojunction Bipolar Transistor

Indium phosphide (InP) wafer have high saturation velocity and electron mobility. This is the reason that they are best to be used for manufacturing optical fiber transmission windows. These windows are found in photodetectors and lasers.

Discovery of Indium phosphide (InP) 100 GHz Oscilloscope

Indium phosphide (InP) wafer has made it possible to produce a revolutionary technology that is useful for making 100 GHz oscilloscopes with the highest bandwidth in the world.

For the first time, new generation chipsets based on the advanced indium phosphide (InP) semiconductor process technology have been successfully accessed. The new integrated circuits will give the possibility to operate oscilloscopes in real-time mode and in equivalent time with bandwidths greater than 100 GHz and with a significantly better background noise level than guaranteed from the tools currently existing in the market.

The recording bandwidth is not the only revolutionary feature of this new oscilloscope. Real-time oscilloscopes will introduce other fundamental innovations, including a new 10-bit analog-to-digital converter, which will allow offering a higher vertical resolution to signals captured with a wide band, and more than one active oscilloscope input channel at maximum bandwidth, to offer a very tight synchronization between the measurement channels.

The professionals who introduced it have continued to innovate in the indium phosphide manufacturing process, which serves to achieve the best possible performance to meet the most demanding measurement needs of the electronics industry. The experience in microwave semiconductors allowed them to develop a new generation production process based on indium phosphide, which allows achieving a decisive leap forward in the performance of oscilloscopes in real-time and in equivalent time, and which will also allow overtime to achieve further performance improvements even for other products.

The electronic design engineers who are working on next-generation high-speed interfaces, such as the new standard system IEEE P802.3bs to 400G and optical systems with coherent modulation terabit speed, they will need suitable oscilloscopes for making electrical characterization parametric measurements.

These are technologies that will play a fundamental role in validating the projects of 5G wireless networks and it is therefore expected that they will generate the need to push high-performance analysis capabilities in real-time and in equivalent time on signals with 100 GHz bandwidths and beyond.

The Engineers hope to improve multiple performance parameters. The new generation of oscilloscopes will offer bandwidth starting at 80 GHz and will reach over 100 GHz. The new instruments will offer lower noise density and higher resolution measurements with extremely high synchronization for multi-channel systems. Whether customers need to measure signals with a higher symbol speed, or signals with higher-order QAM modulations, or even verify the behavior of multichannel systems, this new-generation oscilloscope will be able to meet their requirements. This is possible only due to the existence of Indium phosphide (InP) wafer.

Indium Phosphide (InP) wafer is a semiconductor material composed of indium and phosphorus. Its chemical formula is InP. It has a cubic crystalline structure, identical to that of GaAs and most of the semiconductors. The material is a blessing for the electronics industry due to its outstanding properties such as high limit drift electronic speed, good radiation resistance, and good thermal conductivity. Indium Phosphide (InP) Wafer finds its uses in the production of some types of diodes including LED diodes and laser diodes. It’s not only limited to the electronics industry but it also applications in the medical and other sectors, as described in the article.

Recent Posts

-

Nanocomposites in Food Packaging

The utilization of nanocomposites in food packaging represents a significant advancement in the fiel …19th Apr 2024 -

What is the Difference Between 7075 and 6061 Aluminum Alloy?

When comparing 7075 aluminum alloy to 6061 aluminum alloy, it's essential to understand their disti …5th Apr 2024 -

Iron-Air Batteries: The Ultimate Guide

Iron-air batteries represent a significant breakthrough in energy storage technology, offering a sus …29th Mar 2024