Graphene Oxide Actuators: The Future of Transducers - Nanografi

Graphene oxide actuators represent a cutting-edge technology with immense potential to transform the field of transducers and beyond. Their unique combination of properties, including rapid response, large deformation, and biocompatibility, opens up a wide range of applications across various industries.

From biomedical devices and MEMS to artificial muscles and smart textiles, graphene oxide actuators are poised to drive innovation and offer solutions to complex engineering challenges. Get acquainted with the graphene oxide that underpins the revolutionary potential of graphene oxide actuators - visit website now!

Introduction

Graphene is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice. It is the basic building block of other carbon allotropes like graphite, carbon nanotubes, and fullerenes. Graphene exhibits remarkable electrical, thermal, and mechanical properties. Graphene oxide, on the other hand, is a derivative of graphene obtained by oxidizing it. It contains oxygen functional groups, making it hydrophilic and easier to process. Graphene oxide has applications in areas such as materials science, nanotechnology, and biomedical research. To get more information about applications of reduced graphene oxide, you can read our blog.

Actuators are devices that convert energy into mechanical motion or physical action and play a crucial role in controlling and manipulating objects or systems. They come in various types, including electrical, hydraulic, pneumatic, thermal, and mechanical, each suited for different applications. Actuators are used extensively in robotics, automotive, aerospace, industrial automation, and medical devices. They can be controlled manually, through sensors and feedback systems, or autonomously via controllers. Materials, efficiency, and emerging technologies are key considerations in actuator design and development, making them essential components across a wide range of industries

Working Principle of Graphene Oxide Actuators

Graphene oxide actuators operate based on the ability of graphene oxide, a two-dimensional carbon material with oxygen functional groups, to absorb and release water molecules in response to changes in humidity or temperature. This absorption and release cause the material to swell and shrink, leading to mechanical deformation that can be controlled. By adjusting environmental conditions, such as humidity levels, these actuators can generate controlled motion, making them suitable for micro- and nano-scale devices like micro-robots and sensors. Researchers are exploring their potential in various applications due to their precise and responsive movement capabilities.

Structural Characterization of the Graphene Oxide Actuators

Structural characterization of graphene oxide actuators involves using various analytical techniques to understand their composition, morphology, and properties. Techniques such as scanning and transmission electron microscopy, X-ray diffraction, Raman spectroscopy, X-ray photoelectron spectroscopy, atomic force microscopy, Fourier transform infrared spectroscopy, and thermal analysis are commonly employed. These methods help researchers investigate the layered structure, chemical composition, defects, and response to environmental changes of graphene oxide actuators. This comprehensive characterization is crucial for tailoring and optimizing their performance in specific applications.

Fabrication of the Graphene Oxide Actuator

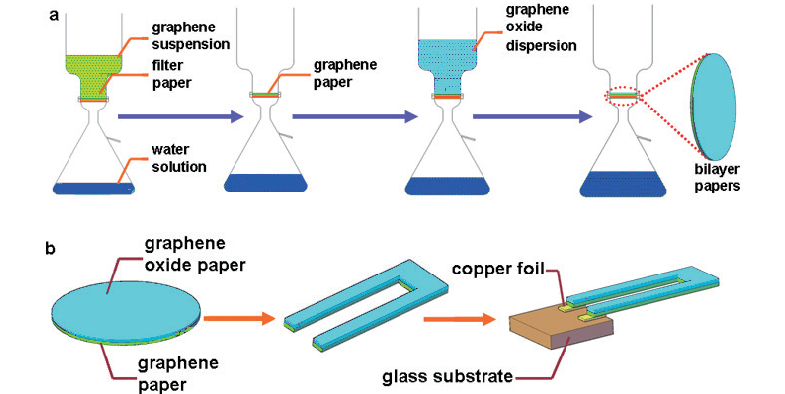

The fabrication of graphene oxide actuators involves several steps to create the functional material and assemble it into an actuator device. Here's a general overview of the fabrication process:

- Graphene Oxide Synthesis:

Start by synthesizing graphene oxide. This can be achieved through the oxidation of graphite using strong oxidizing agents such as sulfuric acid and potassium permanganate. This process introduces oxygen functional groups onto the graphene sheets.

- Isolation and Purification:

After the synthesis, the graphene oxide is typically dispersed in a solvent to form a stable suspension. Ultrasonication or other mixing methods are often used to achieve good dispersion.The suspension may undergo purification steps, such as filtration or centrifugation, to remove residual impurities.

- Coating or Deposition:

The graphene oxide suspension is then applied to a substrate. This can be done by methods like drop casting, spin coating, or dip coating.The choice of substrate depends on the desired application and can range from flexible polymer films to rigid substrates like silicon or glass.Drying and Annealing:

The coated substrate is allowed to dry to remove the solvent. This step is crucial to achieve a solid graphene oxide film.In some cases, annealing (heat treatment) may be performed to improve film adhesion and reduce defects.

- Device Fabrication:

Depending on the intended actuator design, further processing steps may be necessary. For example, electrodes may be patterned or added to enable electrical actuation.The actuator structure may also incorporate other materials or components, such as polymers or hydrogels, to facilitate mechanical deformation.

- Activation:

Graphene oxide actuators typically respond to changes in humidity or temperature. To activate the actuator, it is exposed to the relevant environmental conditions.

- Characterization:

After fabrication, the actuator's properties and performance are characterized using techniques like scanning electron microscopy, X-ray diffraction, and Raman spectroscopy, as mentioned in the previous response.

- Application-Specific Optimization:

Depending on the application, additional modifications and optimizations may be required to achieve the desired actuation behavior, such as controlling the degree of swelling and shrinking.

Figure 1: Fabrication of graphene based electrothermal cantilever actuator.

Advantages of Graphene Oxide Actuators

Graphene oxide actuators offer several advantages, including large deformation capabilities, rapid response to environmental changes, low operating voltage, biocompatibility, flexibility, tunable properties, suitability for miniaturization, environmental responsiveness, low cost, and versatility in various applications. These actuators have the potential to revolutionize fields like robotics, biomedical devices, and micro-electromechanical systems (MEMS) due to their unique properties and controllable actuation behavior. However, researchers continue to address challenges related to long-term stability and hysteresis to fully harness their potential.

Graphene oxide actuators offer several notable advantages that make them attractive for various applications:

Rapid Response: They exhibit fast response times to environmental stimuli, such as changes in humidity or temperature, enabling quick and precise actuation.

Large Deformation: Graphene oxide actuators can achieve significant mechanical deformation, making them suitable for applications requiring precise and controlled motion.

Biocompatibility: They are biocompatible, which means they can be safely used in biomedical devices and applications, including drug delivery and tissue engineering.

Low Operating Voltage: Some graphene oxide actuators can operate at low voltages, reducing power consumption and making them suitable for portable and low-power devices.

Flexibility: They can be integrated into flexible substrates and materials, enabling the development of conformable and wearable devices.

Tunable Properties: The properties of graphene oxide, such as the degree of oxidation and functional group density, can be adjusted to customize actuation behavior for specific applications.

Miniaturization: Graphene oxide actuators are well-suited for micro- and nano-scale applications, making them valuable in fields like MEMS, micro-robotics, and lab-on-a-chip devices.

Environmental Responsiveness: They can respond to changes in humidity and temperature, making them versatile for environmental monitoring and control systems.

Low Cost: The production of graphene oxide is relatively inexpensive compared to some other advanced materials, potentially reducing the cost of actuator fabrication.

Versatility: Graphene oxide actuators can be integrated into a wide range of systems, including sensors, micro-robots, biomedical devices, and more, due to their versatile and controllable actuation.

To discover about all the uses and applications of graphene, you can read our most popular blog.

Applications of Graphene Oxide Actuators

Biomedical Devices

Graphene oxide actuators offer promising applications in the field of biomedical devices due to their unique properties and biocompatibility. They can be utilized in drug delivery systems, microfluidics and lab-on-a-chip devices, biomedical sensors, tissue engineering, microscale surgical tools, biomedical micro-robots, implantable devices, biosensors, wearable health devices, and neuroprosthetics. These applications range from controlled drug delivery and tissue engineering to minimally invasive surgery and neural interfaces. However, ongoing research is essential to ensure their long-term stability, safety, and effectiveness in biomedical applications.

Micro-Electro-Mechanical Systems (MEMS)

Graphene oxide actuators find diverse and valuable applications within Micro-Electro-Mechanical Systems (MEMS). Their rapid response to environmental changes, compact size, and precise control make them ideal for various MEMS applications. These include micro-valves and pumps for fluid control, micro-mirrors for optical adjustments, micro-sensors for enhanced feedback, micro-grippers and manipulators for precise handling, and actuators in MEMS switches and micro-robots. Additionally, they contribute to energy harvesting and vibration damping within MEMS devices. Graphene oxide actuators are poised to significantly enhance the capabilities of MEMS technology, provided that ongoing research continues to optimize their performance for specific applications within this field.

Artificial Muscles

Graphene oxide actuators hold significant promise in the field of artificial muscles, offering a wide array of applications due to their rapid response, controllable actuation, and versatility. These applications encompass soft robotics, prosthetic limbs, exoskeletons, biomimetic devices, artificial organs, haptic feedback systems, aerospace, biohybrid devices, muscle rehabilitation tools, and textile-based actuators. Their potential to replicate the functionality of natural muscles in a range of contexts, from healthcare to entertainment, is driving ongoing research and development in this field. However, further work is required to optimize their performance and durability for specific applications within the domain of artificial muscles.

Innovative Research and Upcoming Trends

Innovative research and upcoming trends in graphene oxide actuators are driving their expanded applications and enhanced performance. Key areas of focus include advanced materials and composites, 3D printing, smart textiles, energy harvesting, biomedical advancements, environmental sensors, AI integration, miniaturization, biomechanics, sustainability, and green technology. These trends are poised to revolutionize industries ranging from robotics to healthcare and environmental monitoring, as researchers and engineers harness the unique properties of graphene oxide to develop cutting-edge technologies and solutions. Interdisciplinary collaboration will continue to play a crucial role in advancing these exciting developments.

Conclusion

As research and development in this field continue to progress, we can anticipate breakthroughs in materials science, manufacturing techniques, and application-specific optimizations. These advancements will further expand the capabilities of graphene oxide actuators, making them an integral part of the future of transducers and beyond.

However, challenges like long-term stability, scalability, and cost-effectiveness must also be addressed. Collaborative efforts among scientists, engineers, and innovators are essential to overcome these challenges and fully unlock the potential of graphene oxide actuators. With continued research and interdisciplinary collaboration, graphene oxide actuators are poised to play a pivotal role in shaping the future of technology and contributing to a wide array of groundbreaking applications.

References

60 Uses and Applications of Graphene – Nanografi - Nanografi Nano Technology. (n.d.). Retrieved March 14, 2024, from https://nanografi.com/blog/60-uses-and-applications-of-graphene-nanografi-/

MEMS - Wikipedia. (n.d.). Retrieved March 14, 2024, from https://en.wikipedia.org/wiki/MEMS

Raman spectroscopy - Wikipedia. (n.d.). Retrieved March 14, 2024, from https://en.wikipedia.org/wiki/Raman_spectroscopy

Rogers, G. W., & Liu, J. Z. (2012). High-performance graphene oxide electromechanical actuators. Journal of the American Chemical Society, 134(2), 1250–1255. https://doi.org/10.1021/JA2096199/SUPPL_FILE/JA2096199_SI_001.PDF

Synthesis of Reduced Graphene Oxide - Nanografi Nano Technology. (n.d.). Retrieved March 14, 2024, from https://nanografi.com/blog/synthesis-of-reduced-graphene-oxide/

What Are the Applications of Reduced Graphene Oxide? - Nanografi - Nanografi Nano Technology. (n.d.). Retrieved March 14, 2024, from https://nanografi.com/blog/what-are-the-applications-of-reduced-graphene-oxide-nanografi-/

Zhou, Y., Bi, H., Xie, X., & Sun, L. (2013). Fabrication of graphene based electrothermal cantilever actuator. The 8th Annual IEEE International Conference on Nano/Micro Engineered and Molecular Systems, 911–914. https://doi.org/10.1109/NEMS.2013.6559871

Recent Posts

-

Advanced Materials for Unmanned Aerial Vehicle (UAV) Protection Against Laser

Consider a UAV on a critical mission, rendered inoperative by a sudden laser attack. With the increa …26th Jul 2024 -

Simulation and Modeling of Material Properties

Our world is composed of a dazzling array of materials, each with its own unique properties that dic …19th Jul 2024 -

Advanced Coatings for Superior Corrosion and Wear Resistance

Corrosion and wear pose significant challenges across various industries, leading to substantial eco …12th Jul 2024