Uses of Graphene Sheet Films - Nanografi Blog

Graphene sheet films, just like graphene, are two-dimensional graphite with a lot of useful properties. Graphene sheet, Pyrolytic Graphite Sheets, and graphene have similar atomic structure with graphite, a single layer of carbon atoms with a hexagonal configuration. Graphene sheets can be obtained via numerous way. This article will discuss the graphene sheet films's properties, ways to synthesize them, and their applications.

Click Image to Find out more about Graphene in this comprehensive post

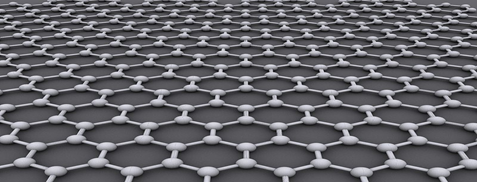

Graphene sheet films and graphene are two-dimensional exfoliated graphite with exceptional physical and chemical properties. Particularly and technically, graphene sheets comprise a single layer of carbon atoms with a hexagonal configuration of carbon rings similar to honeycomb lattice. Graphene sheet films have similar atomic structure compared to that of graphite which is a stack of thousands of these single layers bound to each other using Van der Waals forces. Graphene itself could consist of two or more layers with the adjacent graphene sheets being incommensurate 1. Free monolayer graphene films retain the ultrahigh thermal conductivity property of the graphene with the thermal conductivity value as much as 3000 W/m.K. They also maintain excellent flexibility and have lower density compared to the most commonly used metals for heat dissipation. The graphene sheet films synthesized by numerous suggested methods appear to have different macro-scale morphology yet similar micro-scale morphology thanks to the annealing at higher temperatures. Graphene sheet films have shiny metallic color with the thickness of about 7.5 micro-meter.

Graphene Sheet Films Properties

Considering the one-atom-thick planar sheet with sp2 hybridization of carbon-carbon binding, graphene has been the center of attention thanks to its remarkable structure and the properties. Graphene sheets with their single layer nature have interesting and unique electronic properties owing to their two-dimensional structure. The electronic behavior of graphene sheet films is due to the concepts as the bandgap width, the half-integer quantum hall effect, ballistic and specific electron transport. The properties of graphene like Young’s modulus and electrical conductivity depend on the size of graphene sheets as the number of carbon rings along its length or its minimum length. The graphene sheets length has to be so long to be favorable enough to fit in the nanoscale homogenization criteria 1. In fact, the considerable electronic and electric properties among carbon nanotubes and fullerenes originate from the graphene sheets. Carbon nanotubes are regarded as thin cylinders made of a carbon sheet with almost the similar properties. As it has been proved, two-dimensional (2D) crystals of carbon are zero bandgap semiconductors that contribute to the ultimate 2D electron system and show the existing electronic properties such as electrons massless Dirac fermions behavior and the room temperature anomalous quantum hall effect 2.

Figure 1. The hexagonal structure of graphene

Preparation and Synthesis of Graphene Sheet Films

Currently, numerous methods are used to prepare and synthesize graphene sheet films namely thermal and chemical exfoliation, vacuum thermal annealing, scotch tape, direct ultrasound sonication, chemical vapor deposition (CVD), graphene oxide reduction, micromechanical cleavage with each method having their advantages and disadvantages along with their compatibilities based on their application. However, it is kind of not so common to apply these techniques for mass production purposes and industrial scales. Based on a method, graphene oxide, which is itself obtained by oxidizing graphite, is used to achieve exfoliated 2D graphene sheet films 3. In another method, the single layer graphene sheet films are prepared though exfoliating the expandable graphite at temperatures over 1000°C for a minute time. In the next step, the NaCl crystalline is applied to grind graphite for some three minutes to exfoliated it to result in homogenous grayish mixture. Later, the exfoliated graphite is collected by aqueous dissolution of NaCl and treated with oleum at room temperature for 24 hours. The resulting sample is ultra-sonicated in N,N’-dimethylformamide for five minutes 4. In general, graphene sheet films are prepared through carbon evaporation on an organic precursor like Poly methyl methacrylate (PMMA) and the controlled deposition on a substrate 5. Other methods to be mentioned are vacuum filtration method, direct evaporation method other assembling methods.

Application of Graphene Sheet Films

The huge contribution of graphene sheet films thermal conductivity to various thermal management areas and studies namely heat dissipation materials and thermal interface materials with truly promising outcomes has risen a huge interest to apply them so broadly and practically. As an instance to this, the graphene sheet films thermal management capabilities have been demonstrated through applying them in 7w high-bright LEDs as hot spots with the recorded lowered temperatures, whereas in the absence of the graphene sheet films resulted in a rise in the temperature. The ultra-flexible, stretchable and lightweight graphene sheet films application cloth has led to a fast temperature increase with the consequent fast decrease to room temperature in 5 minutes 6. With regard to the thermal properties, large surface area per unit volume, excellent electrical mechanical and structural characteristics, graphene sheet films have found many applications like antibody-functionalized graphene sheets as potential agents for microbial and mammalian detection and diagnostic devices.

The unique transparency of graphene sheet films makes them perfect candidates in developing biosensors. In so doing, a sensor-coated graphene can have as much contact in aqueous solutions and serve as an uncoated sensor while being protected chemically and mechanically. Through integrating graphene sheets of less than 0.4 nm into a nanopore, the problem of bottle-neck for nanopore-based DNA sequences with single molecule can be solved. They have been applied in elastic composite materials and condom fabrication. In a recent application, implantable sensors based on transparent and flexible graphene is used to view the brain tissue with the optical transparency of 90%. Graphene sheet films can transform into liquid crystal droplets through placing the droplets in a solution with changing pH. In this way, the graphene droplets’ structure changes while a magnetic field is applied making it a drug carrier with release quality right in the target tissue. Another application of graphene sheet films is in detecting disease as it has been demonstrated that graphene changes shape when it is exposed to some particular disease markers. In a medical application, graphene sheets termed as “flying carpet” serve as a drug delivery platform to deliver two anticancer drugs to lung tumors cells. In this application, the doxorubicin drug is encapsulated in the graphene sheets and is released when it reaches to tumor cells.

In a different application, graphene sheets are employed in waterproof transistor designing and fabrication with graphene sheets being grown on metal. Through perforating a graphene sheet with boron nitride nanotubes, a digital switch can be designed with the ratio of 105 at a turn-on voltage of 0.5V. All in all, graphene sheet films are used as transparent conducting electrodes, frequency multiplier, optoelectronics, hall effect sensors, graphene quantum dots,organic electronics,spintronics andconductive ink.

Graphene sheet films inherit the mother graphite excellent conductivity, thermal properties and electronic yet with even more intensified properties have found applications as transistors, semiconductors and biosensing platforms and in drug delivery and cancer therapy. The numerous synthesis and preparation methods as well as the huge source of graphite as the raw material make graphene the subject of a lot of research and applications.

References

1. Harik, V. Nanomechanics of Graphene Sheets and Atomic Registry Matrix Analysis. Mech. Carbon Nanotub. 49–71 (2018). doi:10.1016/b978-0-12-811071-3.00003-2

2. Tang, L. et al. Preparation, structure, and electrochemical properties of reduced graphene sheet films. Adv. Funct. Mater. 19, 2782–2789 (2009).

3. Thema, F. T. et al. Synthesis and characterization of graphene thin films by chemical reduction of exfoliated and intercalated graphite oxide. J. Chem. 3, (2013).

4. Li, X. et al. Highly conducting graphene sheets and Langmuir-Blodgett films. Nat. Nanotechnol. 3, 538–542 (2008).

5. Kathalingam, A. et al. Poly(methyl methacrylate)-derived graphene films on different substrates using rapid thermal process: A way to control the film properties through the substrate and polymer layer thickness. J. Mater. Res. Technol. 8, 3752–3763 (2019).

6. Gong, F. et al. Recent advances in graphene-based free-standing films for thermal management: Synthesis, properties, and applications. Coatings 8, 1–17 (2018).

Recent Posts

-

Reducing the Carbon Footprint of Nanomaterials

The production of nanomaterials is vital for numerous advanced applications, from healthcare to elec …26th Apr 2024 -

Nanocomposites in Food Packaging

The utilization of nanocomposites in food packaging represents a significant advancement in the fiel …19th Apr 2024 -

What is the Difference Between 7075 and 6061 Aluminum Alloy?

When comparing 7075 aluminum alloy to 6061 aluminum alloy, it's essential to understand their disti …5th Apr 2024