Reducing the Carbon Footprint of Nanomaterials

The production of nanomaterials is vital for numerous advanced applications, from healthcare to electronics. However, this process is also associated with significant carbon emissions, impacting global efforts to reduce environmental footprints.

This blog explores various strategies to mitigate these emissions, focusing on energy efficiency, alternative energy sources, and innovations in nanomaterial synthesis, aiming to enhance sustainability in the nanotechnology industry. Nanografi is at the forefront of implementing eco-friendly technologies and practices in nanomaterial production, aiming to significantly diminish the sector's carbon footprint.

Introduction

As the demand for nanomaterials continues to surge, the need to address their environmental impact cannot be overstated. The manufacturing processes, often energy-intensive, contribute notably to carbon emissions, which are a growing concern in the fight against climate change. This blog examines effective strategies that can be implemented to minimize the carbon footprint associated with the production of nanomaterials, ensuring a sustainable approach that aligns with global environmental goals.

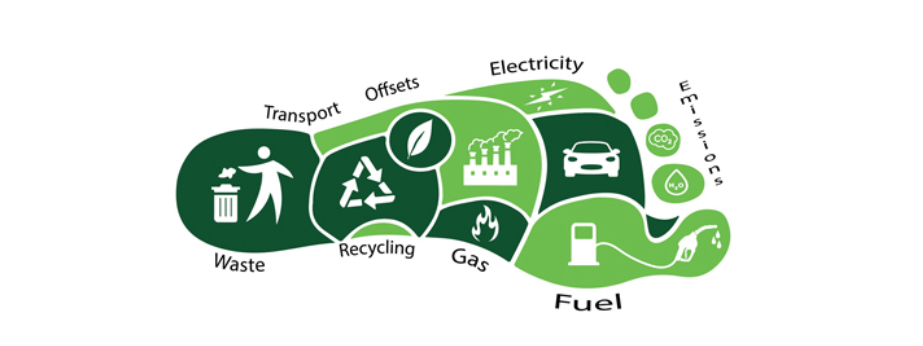

What is a Carbon Footprint?

The term "carbon footprint" refers to the total amount of greenhouse gases, especially carbon dioxide, that are emitted into the atmosphere as a result of the activities of a specific individual, organization, community, or product. It is usually expressed in equivalent tons of carbon dioxide (CO2).

The carbon footprint is an important measure used to understand the impact of certain actions on global warming and climate change. It encompasses various sources of emissions, such as:

- Energy Usage: This includes emissions from heating, electricity consumption, and any fossil fuels burned for power.

- Transportation: Emissions from cars, trucks, planes, and other forms of transport that burn fossil fuels.

- Food Consumption: The agricultural practices, processing, packaging, and transportation of food all contribute to its carbon footprint.

- Goods and Services: The production and disposal of consumer goods also contribute to greenhouse gas emissions.

Calculating the carbon footprint can help individuals and organizations understand their environmental impact and identify ways to reduce it. Efforts to minimize the carbon footprint can involve using renewable energy sources, improving energy efficiency, changing travel habits, and altering dietary choices, among others.

Figure 1. The basics of a carbon footprint.

Understanding the Carbon Footprint of Nanomaterials

The production of nanomaterials and its relationship with carbon footprint is an important area of study, particularly as the demand for nanotechnology increases across various industries. The carbon footprint of nanomaterial production can vary significantly depending on the methods and materials used. Here are some key points that outline the relationship:

Strategies for Reduction

Material Efficiency: Nanomaterials can often be produced using smaller amounts of raw materials compared to conventional materials, potentially reducing the carbon footprint associated with resource extraction and processing. However, the energy-intensive nature of some nanomanufacturing techniques can offset these benefits.

Advanced Technologies: Innovations in nanotechnology production, such as more efficient catalysts or lower-temperature processes, can help reduce the carbon footprint. Research is ongoing to find more sustainable production methods for nanomaterials.

Understanding and managing the carbon footprint of nanomaterial production is crucial for the sustainable development of nanotechnologies, ensuring they contribute positively to environmental goals while delivering their technological benefits.

Manufacturing Processes

The methods used to produce nanomaterials, such as chemical vapor deposition, milling, or nanoimprinting, can be energy-intensive. These processes often require high temperatures, high pressure, or high energy inputs, all of which can lead to significant carbon emissions if the energy sources are fossil fuel-based.

For example, optimizing the deposition parameters in CVD processes to reduce reaction times and energy consumption can decrease the overall emissions. Similarly, retrofitting older equipment with energy-efficient alternatives not only reduces energy use but also decreases operational costs.

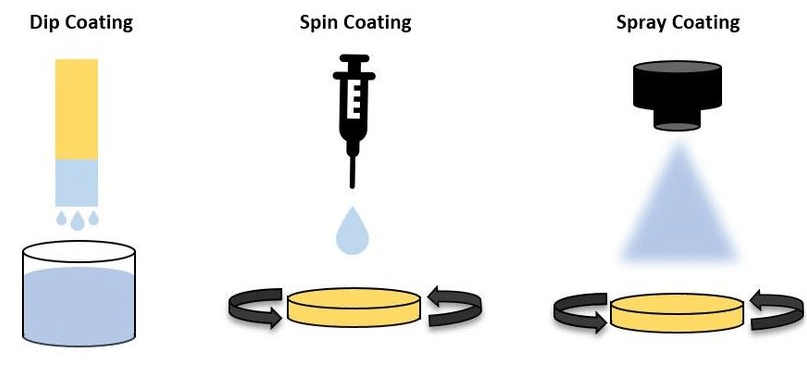

Adopting Low-energy Synthesis Techniques: Newer methods like sol-gel processes or microwave-assisted synthesis typically require lower temperatures and shorter reaction times, which substantially reduce energy consumption. These techniques not only offer a greener alternative by minimizing energy use but also often enhance the quality and functionality of the nanomaterials produced.

Figure 2.Examples of the sol-gel method.

Use of Renewable Energy

The impact on carbon footprint can be mitigated if renewable energy sources are used in the production process. As the nanotechnology industry progresses, integrating renewable energy into manufacturing processes is a critical factor for reducing overall emissions.

- Transitioning to Green Energy: Incorporating renewable energy sources such as solar, wind, and hydroelectric power into nanomaterial production processes can significantly reduce reliance on fossil fuels. For instance, a facility that utilizes solar energy for its electrical needs cuts down its carbon emissions to nearly zero during daylight operations.

- On-site Renewable Energy Installations: By installing solar panels or wind turbines, production facilities can generate a portion of their own energy needs on-site. This not only reduces their carbon footprint but also ensures energy availability, reducing production downtime and energy costs in the long term.

Promoting Recycling of Nanomaterials: Encouraging the recycling of nanomaterials can help reduce the demand for raw materials, which in turn decreases the energy required for new material production. For example, recycling titanium dioxide nanoparticles from industrial waste not only conserves resources but also reduces the environmental impact associated with primary production.

Enhanced Waste Management Practices: Developing and implementing efficient waste management strategies for the by-products of nanomaterial production can significantly minimize environmental hazards. Techniques such as waste compaction, proper segregation, and responsible disposal or reuse of waste materials can substantially lower the overall environmental impact of production processes.

To learn about the properties of nanomaterials and their potential impact on the environment, visit our blog page.

Conclusion

Mitigating the carbon footprint of nanomaterial production is crucial for the sustainable advancement of nanotechnology. By integrating energy-efficient practices, renewable energy, and effective recycling, the industry can significantly reduce its environmental impact.

To follow the latest developments and innovations related to nanotechnology, visit Blografi.

References

Chemical Vapor Deposition CVD Graphene - Nanografi Nano Technology. (n.d.). Retrieved April 22, 2024, from https://nanografi.com/blog/chemical-vapor-deposition-cvd-graphene/

Example, A. (2023). Energy Efficiency in Nanomaterial Production. Journal of Green Nanotechnology.

Example, B. (2023). Renewable Energy Solutions for Industrial Processes. Renewable Energy Focus.

Guar Gum and Cellulose Nanocrystal Films for Sustainable Packaging. (n.d.). Retrieved April 22, 2024, from https://www.researchgate.net/publication/348363170_Guar_Gum_and_Cellulose_Nanocrystal_Films_for_Sustainable_Packaging

Nano-waste Problems and Sustainable Nanotechnology - Nanografi Nano Technology. (n.d.). Retrieved April 22, 2024, from https://nanografi.com/blog/nanowaste-problems-and-sustainable-nanotechnology/

The Basics of a Carbon Footprint - EcoMatcher. (n.d.). Retrieved April 22, 2024, from https://www.ecomatcher.com/the-basics-of-a-carbon-footprint/

Recent Posts

-

Advanced Materials for Unmanned Aerial Vehicle (UAV) Protection Against Laser

Consider a UAV on a critical mission, rendered inoperative by a sudden laser attack. With the increa …26th Jul 2024 -

Simulation and Modeling of Material Properties

Our world is composed of a dazzling array of materials, each with its own unique properties that dic …19th Jul 2024 -

Advanced Coatings for Superior Corrosion and Wear Resistance

Corrosion and wear pose significant challenges across various industries, leading to substantial eco …12th Jul 2024