Carbon Black Nanopowder Characteristics, Production, Sources

Carbon black nanopowder, a significant nanomaterial in industrial and scientific applications, possesses unique characteristics such as high surface area, exceptional electrical conductivity, and excellent mechanical strength.

This article aims to explore the production methods, sources, and essential properties of carbon black nanopowder, shedding light on its importance and versatility in contemporary nanotechnology. As a form of carbon-based nanoparticles, carbon black plays a pivotal role in various fields, including energy storage, catalysis, and advanced composite materials, making it a material of great interest in cutting-edge research and technology. Get acquainted with Nanografi products to achieve the highest quality and most durable form of carbon black nanopowders, essential in significant nanotechnology applications.

Introduction

Carbon black nanopowder and conductive carbon materials are valuable substances with high electrical conductivity and versatile properties. Produced through incomplete combustion or thermal decomposition of hydrocarbons, carbon black nanopowder possesses a high surface area, making it excellent for adsorption and conductive applications.The primary sources of carbon black nanopowder are fossil fuels such as oil and natural gas, though it can also be obtained from other organic materials.Industries ranging from gas purification to electronics capitalize on its distinct characteristics, where it aids in advancing performance and fostering innovation.

What is the History of Carbon Black Nanopowder?

Carbon black is produced through various processes, including the incomplete combustion of fossil fuels such as diesel and fuel oil, as well as the burning of carbon-containing materials like firewood. Historically, carbon black was initially produced in China through incomplete combustion in oil lamps and was used to provide the black pigment in Indian ink.

In 1912, carbon black was discovered to have exceptional reinforcing properties for rubber tires. This discovery was revolutionary for the tire industry as it significantly improved the strength, durability, and wear resistance of rubber tires, making them more suitable for various applications. Since then, carbon black has become an essential ingredient in the rubber industry and is widely used in tire manufacturing, as well as in other rubber products like belts, hoses, and seals.

Therefore, the information provided accurately reflects the historical significance of carbon black in tire reinforcement and other applications.

How is Carbon Black Nanopowder Produced?

Carbon Black Powder is an inorganic carbon material obtained by the thermal decomposition and cracking of non-combustible hydrocarbon substances, such as natural gas, petroleum residues, or coal. Carbon black consists of microscopic particles and is typically in the form of a dark black powder.

The production of carbon black powder is typically carried out in specialized facilities known as "Carbon Black Production Plants." The manufacturing process involves the following steps:

- Raw material preparation: The raw material to be used for carbon black powder production is selected from suitable hydrocarbon sources such as natural gas, petroleum residues, or coal and is prepared for further processing.

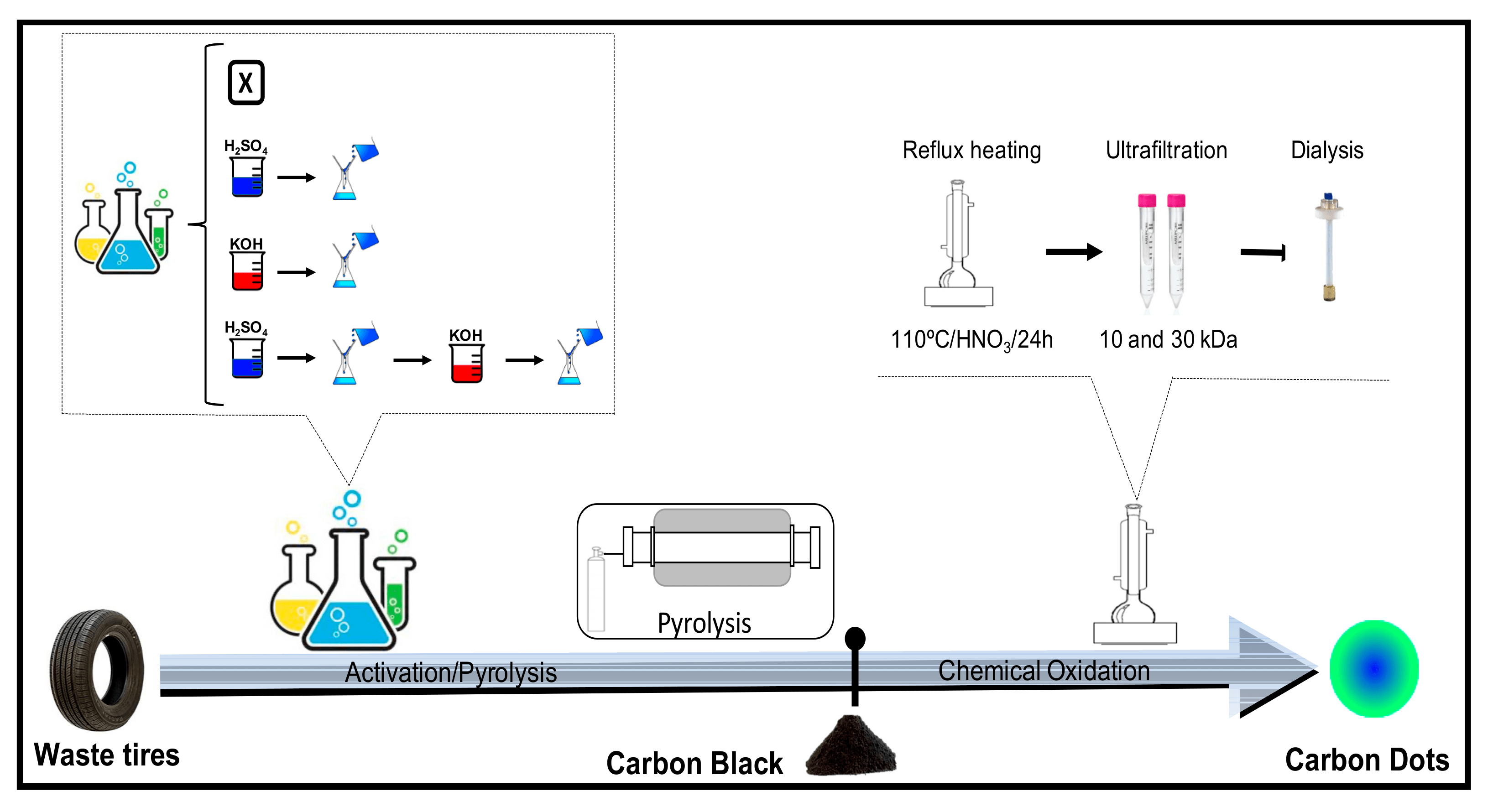

- Pyrolysis: The raw material undergoes thermal treatment known as pyrolysis in an oxygen-free environment at high temperatures (usually between 1000-3000°C). During this process, the raw material is broken down at a molecular level, and carbon black particles are formed. If you interested in learning more about the inert gas condensation and pyrolysis methods in the synthesis of metallic nanoparticles, you can read our blog.

- Cooling and collection: The carbon black particles produced during pyrolysis are rapidly cooled and collected. This step is crucial to ensure the desired properties of the carbon black.

- Processing and purification: The collected carbon black powder undergoes processing and purification. Unwanted by-products and additives are removed to obtain a refined product.

- Storage and packaging: The obtained carbon black powder is stored under suitable conditions and packaged in various containers for distribution to customers.

Carbon black powder finds significant applications as a vital additive in the production of various industrial products, including rubber, plastic, paint, ink, chemicals, batteries, and electrodes. It is valued for enhancing properties such as electrical conductivity, UV resistance, and mechanical characteristics in various applications. However, carbon black production may have certain adverse environmental and health impacts, which is why production processes are strictly regulated and monitored.

Figure 1. Recovery of pyrolytic carbon black from waste tires and the synthesis of carbon dots.

Given a more comprehensive analysis:

Carbon black is produced mainly by incomplete combustion of heavy oil residues using the Oil Furnace Black process (used for 98% of world production). The reaction takes place in an oven in which natural gas is burned in the presence of excess air. The oil charge is introduced radically. The temperature ranges from 1400 to 2000 ° C and the reaction time from 1/100 to 1/10 of a second depends on the type of blackness desired. The combustion gases, containing the carbon black, are rapidly cooled by water spraying and the carbon black is recovered by filtration. For example, Orionused 4000 fiberglass handle filters, 3 m long and 15 to 20 cm in diameter. An inverted gas stream empties the filters alternately every 2 to 3 minutes. The purchase of the heavy oil charge represents more than 30% of the selling price. The production units have an average capacity of 75 t / day and, per plant, there are usually 2 to 5 units. The yields are about 50% of the carbon content of the feed.

In addition, the cracking of acetylene, with temperatures of over 2000 °C gives the purest carbon blacks and have a more conductive character.

Characteristics of Carbon Black Nanoparticles

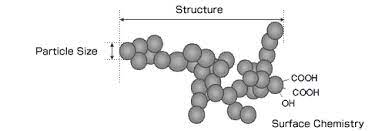

Carbon black nanopowder typically consists of carbon (ranging from 98% to 99.7%), present in the form of spherical particles (ranging from 10 to 500 nm). Their specific surface area ranges from 10 to 300 m2/g, indicating a high surface area per unit mass of particles.

Moreover, there are various grades of carbon black, depending on the raw materials used, combustion conditions, and thermal decomposition processes. These variations result in carbon black with unique properties, making them suitable for different industrial applications. Visit our website to explore a variety of carbon black nanoparticle products in different sizes and quantities.

Figure 2. Main properties of carbon black.

Sources for the Emission of Carbon Black

- Incomplete combustion of firewood, charcoal, and manure, used for the purpose of cooking.

- Combustion of diesel engines in vehicles.

- Burning of agricultural waste and forests.

- Extraction of fossil fuels.

- Burning garbage outdoors or "open sky".

6 Uses of Carbon Black Nanoparticles

- A 7 kg tire contains 3 kg of carbon black which gives it resistance to wear. An automobile (including tires) contains about 18 kg of carbon black. The treads use carbon black of about 30 nm (10 to 20 nm for fast and off-road vehicles. Fine blacks bring hardness; larger blacks retain the flexibility of rubber. Carbon black is currently used in the manufacture of green tires, partly competing with precipitated silica.

- Liquid inks for large prints (newspapers) contain nearly 10% of their mass of carbon black. Fat inks for the offset from 20 to 30%.

- Automotive paints, lacquers for furniture and pianos contain very fine carbon black nanopowder (10 to 20 nm).

- Carbon black (mass contents of 1 to 3%) provides the protection of plastics and elastomers against UV.

- Conductive carbon blacks (150,000 t / yr worldwide), obtained, in part, from acetylene, are used in saline electric batteries (40,000 t / year), high voltage underground cables (60,000 t / year), plastics and conductive rubbers...In the conductive cables, the black conductors are incorporated in the coating of the aluminum strands and thus ensure the equalization of the electric field and the prevention of the corona effect.

- It is also used as a model for diesel emission particles without sticking to metals and hydrocarbon.

Figure 3. Applications of carbon black.

Use of Carbon Black Nanopowder in the Rubber Industry

As indicated above, the majority of the use of Carbon Black is in the Rubber Industry, it’s around 93%. This use can be characterized into 2 major groups: mechanical rubber goods and tires. The durability and performance of the rubber products are increased due to reinforcing characteristics of carbon black nanopowder. The use of Carbon Black in the rubber industry is classified as N100-N900 black series.

Use of Carbon Black Nanopowder in Other Sectors (Plastics, Coatings, Inks, etc.)

The rest 7% use of carbon black nanopowder is in different sectors, which includes coating, inks, and plastics. More applications involve toners, batteries, sealants, etc. In these products, the blackness, UV light protection, and conductivity properties of carbon black nanopowder are used.

Additionally, the below sectors also benefits from reinforcing, staining, and UV protection properties of Carbon Black nanopowder:

- Aerospace industry

- Boat coatings

- Home appliances

- Computer cases

- Furniture

- electronics

- General industry

- Pipe coatings

- Nava industry

- Rubber for non-automotive applications

- Films for packaging

To get more information about properties and applications of carbon black, read our blog.

Conclusion

In summary, carbon black nanopowder is a versatile nanomaterial with high conductivity, surface area, and strength. Its history dates back to ancient China, but its breakthrough came in 1912 when it strengthened rubber tires. Produced through controlled pyrolysis, it finds use in various products, enhancing properties like conductivity and UV resistance.

Used mainly in tires and rubber goods, it improves durability and performance. Additionally, it's a key ingredient in inks, coatings, plastics, and electronics. Its varied forms cater to specific applications, and its environmental impact is managed.

Carbon black nanopowder's role in modern nanotechnology is undeniable, driving innovation across sectors and enabling advanced materials with exceptional properties. Nanografi, one of the pioneers in graphene production, continues to improve its products every day and strives to offer you the best quality.

References

Applications (rCB) - Black Bear. (n.d.-b). Retrieved March 5, 2024, from https://blackbearcarbon.com/products-2-2/

Carbon Black Properties and Applications - Nanografi Nano Technology. (n.d.). Retrieved March 5, 2024, from https://nanografi.com/blog/carbon-black-properties-and-applications/

C-NERGY Super C65 Conductive Carbon Black - Nanografi Nano Technology. (n.d.). Retrieved March 5, 2024, from https://nanografi.com/blog/cnergy-super-c65-conductive-carbon-black/

González-González, R. B., González, L. T., Iglesias-González, S., González-González, E., Martinez-Chapa, S. O., Madou, M., Alvarez, M. M., & Mendoza, A. (2020). Characterization of Chemically Activated Pyrolytic Carbon Black Derived from Waste Tires as a Candidate for Nanomaterial Precursor. Nanomaterials 2020, Vol. 10, Page 2213, 10(11), 2213. https://doi.org/10.3390/NANO10112213

Methodology followed for the recovery of pyrolytic carbon black from... | Download Scientific Diagram. (n.d.). Retrieved March 5, 2024, from https://www.researchgate.net/figure/Methodology-followed-for-the-recovery-of-pyrolytic-carbon-black-from-waste-tires-and-the_fig1_345438268

Nanotechnology to Better the Diesel Engine Performance - Nanografi Nano Technology. (n.d.). Retrieved March 5, 2024, from https://nanografi.com/blog/nanotechnology-to-better-the-diesel-engine-performance/

Three Main Properties of Carbon Black. (n.d.). Retrieved March 5, 2024, from http://www.carbonblack.jp/en/cb/tokusei.html

Recent Posts

-

Reducing the Carbon Footprint of Nanomaterials

The production of nanomaterials is vital for numerous advanced applications, from healthcare to elec …26th Apr 2024 -

Nanocomposites in Food Packaging

The utilization of nanocomposites in food packaging represents a significant advancement in the fiel …19th Apr 2024 -

What is the Difference Between 7075 and 6061 Aluminum Alloy?

When comparing 7075 aluminum alloy to 6061 aluminum alloy, it's essential to understand their disti …5th Apr 2024