Description

1 piece/16,248.75 €

Please contact us for quotes on larger quantities !!!

Three Roll Mill Lab Model

Three roll mills can serve various purposes such as homogenizing, venting or grinding. Our three roll mill lab model has powerful performance due to its state-of-art control, aerodynamic design and stainless steel parts. To obtain small volume production in laboratories, three roll mill is an ideal tool for mixing electronic thick film inks, high performance ceramics, cosmetics, paints, printing inks, adhesives, epoxy, sealants, pharmaceuticals, chemicals, dental cosmetics, carbon/graphite, foods and many other viscous materials. Three roll mills can dissipate all kinds of agglomerates and also reduce the particle sizes. Therefore, greatest fine particles with high quality and dispersion can be obtained by our three roll mills machine. With our professional technical and sales team, you will experience the highest level of quality of products, services, and technical supports.

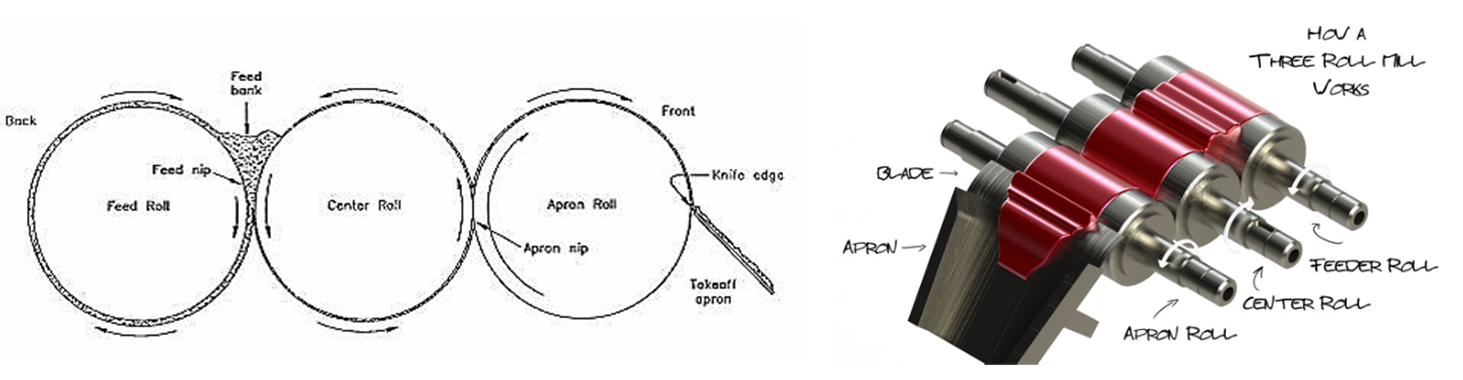

Three Roll Mills Machine is consisting of three horizontal rollers which rotate opposite direction from the adjacent one with different speeds. Very small gaps between rolls create huge shear force which can produce finely dispersed, mixed and homogenized viscous substances. The material is poured between feeder roll and center roll and then with high shear force material moves through apron roll. The apron part collects the processed mixture from apron roll by the help of a blade. Following shape is illustrating the movement of the substance through the rollers. Until perfectly dispersed material obtained, three roll milling cycles can be performed many times.

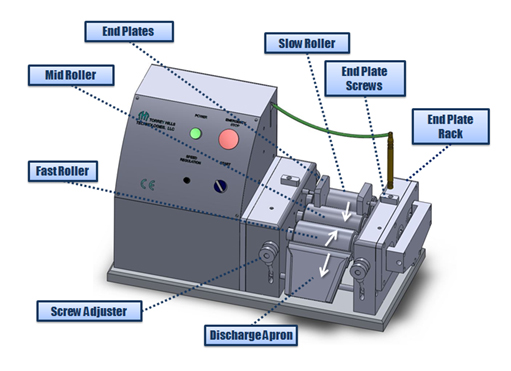

Three Roll Mills is consisting from machine base, cover and roller bearing, Teflon endplates, collecting blade, cooling system, gears and wheels. Six bearing bases for high speed, medium speed and low speed roller exist in the machine. Medium speed roller is fixed to the base and cover while fast and slow rollers can move horizontally to reach desired grinding fineness. The apron can be made up from either steel or Teflon materials. There is also cooling system through the rollers. Inlet and outlet parts on the machine provide the movement of either cooling water or heating liquid such as hot oil to enhance the process quality of substances. The physical structure of the machine can be seen in the following image.

Special Properties of Three Roll Mill Lab Model

- Three Roll Mills Lab Model can produce 30 pounds or 3.75 gallons per hour which is higher throughput than most competitors’ model.

- Rolls are made up from 420J2 stainless steel to prevent rust or erosion.

- Rolls are designed for either cooling or heating.

- Rollers are ground to 5 µm concentricity and 0.5 µm surface finish for precise applications

- Variable speed control allows adjustable/slower speed runs

- For safety usage, emergency pull cord on top of the machine and stop/start buttons are placed on easily accessible part of the machine

- Roller spacing can be controlled manually with four small hand wheels.

- Easily adjustable Teflon end plates

Technical Properties of Three Roll Mill Lab Model

|

Parameters |

|

|

|

Roller Material |

Stainless Steel |

|

|

Diameter of Roller |

2.5” (65 mm) |

|

|

Length of Roller |

5.0” (127 mm) |

|

|

Roller Speed Ratio (Fixed) |

1:2:4 |

|

|

Speed of Roller (RPM) |

Feed Roller |

0-108 |

|

Center Roller |

0-216 |

|

|

Apron Roller |

0-432 |

|

|

Motor Power |

3/4HP / 55 kW |

|

|

Weight |

165 lbs (75 kg) |

|

|

Dimensions |

25”x11”x15” (635 mm x 280 mm x 381 mm) |

|