Titanium Carbide Nanoparticles: History, Properties, Synthesis, Applications

Titanium carbide is the binary compound and is an extremely hard refractory ceramic material ( Mohs 9-9.5) similar to tungsten carbide. It is the only carbide in the titanium - carbon system. Like Tungsten Carbide (WC) and Tantalum Carbide (TaC), it is also an important component of cemented carbides used for cutting tools. In addition, titanium carbide is gray in color. The nanoparticles of Titanium Carbide have large surface area and are more effective in terms of properties and applications. A nanoparticle is a particle whose size is less than 100 nanometers. One nanometer is one-billionth of a meter. So, in this article, we’ll study everything about Titanium Carbide (TiC) Nanoparticles.

Description and History of the Discovery of Titanium Carbide Nanoparticles

Titanium carbide occupies a special place among the compounds of the transition metal of the periodic system of chemical elements. It is distinguished by its special hardness, heat resistance and durability, which determines its wide use as a base for hard alloys that do not contain tungsten. The chemical formula of this substance is TiC. Externally, it is a light gray powder.

Its production began in the 20s of the twentieth century, when companies engaged in the production of incandescent light bulbs were looking for an alternative to the expensive technology of production of tungsten filaments. As a result, a method for producing cemented carbide was invented. This technology was less expensive, since the raw material, titanium dioxide, was cheaper.

In 1970 the use of titanium nitride began, which made it possible to increase the viscosity of the cemented compounds, while the additives of chromium and nickel made it possible to increase the corrosion resistance of titanium carbide. In 1980, the process of sintering the powder under the influence of uniform compression (pressing) was developed. This has improved the quality of the material. Sintered carbide powders are currently used in technological areas where high resistance to temperature, wear and oxidation is required.

Crawford-Voelker lamp with titanium-carbide filament and U-shape envelope. Invented by William Lawrence Voelker. From National Museum of American History

Properties of TiC Nanoparticles

Titanium Carbide Nanoparticles appears as light brown to dark brown or black, powdery substance. In its pure form, when not mixed with other substances, it is very good and feels slippery to the touch. Titanium Carbide Nanoparticles are practically insoluble in water, very stable in the presence of acids and oxidants, but soluble in mixtures of nitric acid and hydrofluoric acid. At a very high temperature (>1000 °C), it reacts with the air, forming TiO and TiN.

Let’s study some of its important properties in detail:

1. Hardness of Titanium Carbide Nanoparticles

Titanium Carbide Nanoparticles are very hard that, when combined with its lubricating properties, makes it an attractive substance for coating drills. If a tool bit does not contain tungsten, it can be made with Titanium Carbide Nanoparticles in a cermet nickel-cobalt matrix. This will improve the cutting speed of the tool, as well as boost the precision of the tool and the smoothness of the workpiece.

Due to the extremely high hardness of TiC, especially in the area of metal forming of thick sheets, significant improvements have been noticed. The CVD coating technology ensures the highest adhesive strength and wear reserve for tools that are not too critical in terms of dimensional accuracy. After coating, a high-gloss polish of the functional surfaces ensures friction-reducing and film-promoting surfaces.

Due to its high hardness, it is resistant to wear which makes it a good choice for cutting tools like dies, punches, and mills. Of the other natural carbides, titanium carbide is important because of its intrinsic strength. The force comes because of the arrangement of the molecules of the solid.

2. Lubricating Properties of TiC Nanoparticles

The potential of Titanium Carbide Nanoparticles as a lubricant has been tested (at the microscopic scale using an atomic force microscope) to compare its friction properties with those of titanium nitride and vinyl chloride. Titanium carbide Nanoparticles had the lowest frictional responses of the three. Its lubricating properties were superior to those of other substances regardless of the shape and composition of the tips used for the tests. The other substances also showed a strong dependence on counterface composition, which titanium carbide lacked.

3. Chemical properties of Titanium Carbide Nanoparticles

Titanium Carbide Nanoparticles are very stable. The boiling point of Titanium Carbide is 4820 degrees Celsius. Its melting point is 3140 degrees Celsius. In terms of elements, carbon, tungsten, and rhenium have higher melting points than titanium carbide. Its molecular weight is 59.89 g/mol.

4. Storage for TiC Nanopowder

The humidity will affect its diffusion performance and properties, therefore, this product should be sealed in vacuum and stored in a cool and dry room and it should not be exposure to air. Moreover, the product should be avoided under tension.

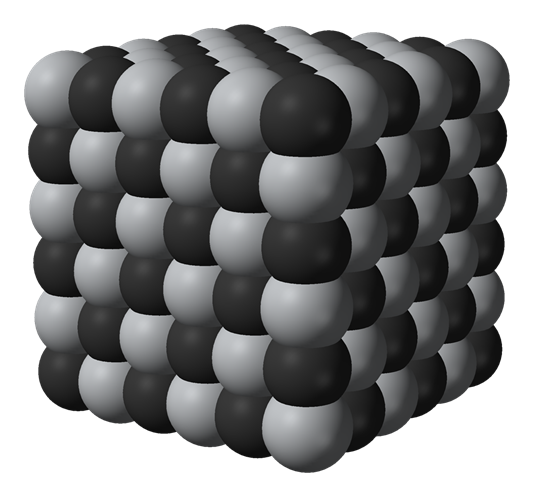

Structure of Titanium Carbide Nanoparticles

Titanium carbide crystallizes with a face-centered cubic structure, with a lattice constant a = 432.8 pm. This structure is similar to that of sodium chloride; also TiN and ZrN crystallize in the same structure. It is often a non-stoichiometric compound, but very homogeneous samples are obtained between TiC 0.5 and TiC 0.98, where part of the positions of the carbon atom are vacant. For these characteristics, TiC is classified as interstitial metal carbide.

Structure of Titanium Carbide

Synthesis of Titanium Carbide NP

Titanium Carbide can be synthesized by placing titanium particles, titanium dioxide or a titanium salt, in carbon and heating it to high temperatures, pyrolyzing the carbon and coating the particles with carbon. These particles are then heated in an inert atmosphere to produce titanium carbide. Titanium Caribe is then converted into nanoparticles.

Titanium carbide is actually prepared in various ways. The most commonly used synthesis reacts titanium dioxide with charcoal at 2000 ° C in a hydrogen atmosphere:

TiO2 + 3C → TiC + 2CO

Otherwise, it can proceed by direct synthesis at high temperatures starting from the elements in the form of powder:

Ti + C → TiC

or use methane gas as a carbon source:

Ti + CH4 → TiC + 2H2

In chemical vapor deposition (CVD) as the starting material for titanium, titanium tetrachloride is used, which is a very volatile compound:

TiCl4 + CH4 → TiC + 4HCl

Sometimes it is preferred to directly synthesize solid solutions of carbides of different metals; these materials are used to make tools:

TiO2 + WC + 3C → TiC + 2CO

Applications of Titanium Carbide Nanoparticles

Titanium carbide has a number of properties that have secured its demand in the industry for many years. The main ones include High hardness, Fire resistance, High melting point, high resistance to abrasion, and good thermal conductivity. Thanks to these qualities, it is used for coating in the manufacture of various types of instruments, including high-speed drills. This contributes to a significant increase in the efficiency of production processes in the metalworking industry, coal industry, and other industries.

Given below are the main applications of Titanium Carbide Nanoparticles.

1. Titanium carbide Nanoparticles are the hardest of the transition metal carbides, but they are too fragile to be used pure. They are added in percentages of 5–30% (by weight) to cemented tungsten-based carbides to increase the hardness and resistance to high-temperature cutting tools.

2. Sometimes TiC is used to cover the cutting surfaces of these tools. Tungsten-free cutting tool bits can be obtained by combining TiC Nanoparticles, molybdenum carbide, and nickel.

3. Titanium Caribe Nanoparticles are used as alloy additives.

4. Titanium Caribe Nanoparticles are used as surface materials.

5. This compound has excelled in the production of grinding, grinding wheel, etc.

6. Titanium Caribe is used as welding and current drilled wire.

7. Titanium Caribe Nanoparticles are used in the preparation of cermet.

8. Titanium Caribe Nanoparticles are used for abrasion-resistant surface coating on metal parts, such as tool bits.

9. Titanium Caribe Nanoparticles are used for heat shield coating for atmospheric return of spacecraft.

10. TiC is also used in general toolmaking and in the chemical industry as an essential component of the sintered material ferrotitanium.

11. Titanium Caribe Nanoparticles are used in the production of wear-resistant materials, sharp tools, etc.

12. Titanium Caribe Nanoparticles coating can improve the alloy, abrasive steel bearings, pipes, and cutting tools.

13. They are used in the preparation of titanium-foamed ceramic material. The foamed ceramic incorporates filters for any type of fluid containment to work effectively, except that the filtration mechanism agitates the adsorption.

14. The application of the Titanium Carbide Nanoparticles layers for metal forming takes place by the CVD process at about 1000 °C. This ensures maximum adhesion. The higher layer thickness of up to 9 μm, which is possible due to the CVD process, is a welcome wear reserve for many applications.

15. Titanium Carbide Nanoparticles have become the basis of modern high-hardness materials, heat-resistant electrodes industrial arc lamps, wear-resistant drilling equipment, and special tools. In powder form, it is used as an additive to graphite and as a substitute for graphite.

16. In electrolysis, TiC serves as an electrode together with a mercury cathode. Such electrodes are indispensable in the electro-autogenous cutting of steel underwater - they allow 6-10 times lower consumption of the electrode, compared to conventional electrodes. Titanium Carbide electrodes have the following composition: Ti 79.2-80%; C of 0.1 to 0.2%; C tot. 19.4 - 20.2%; Fe 0.1 - 0.6%.

17. TiC nanoparticles are used for the coating of graphite electrodes of electric arc furnaces.

18. TiC nanoparticles are also used in the production of heat-resistant screens of combustion plants, seat covers thermocouples, housing crucibles, boats, glass, semiconductors, metals, and non-metals.

Titanium carbide is a compound of titanium and carbon. It is characterized by a particularly high hardness of 9 – 9.5 Mohs. It is an extremely hard refractory ceramic material, similar to tungsten carbide. The nanoparticles of Titanium Carbide are less than 100 nm in size. The nanoparticles of Titanium Carbide possess high purity, high wear resistance, narrow range particle size distribution, and larger specific surface area. Also, the product has good conductivity. The nanoparticles of Titanium Carbide can be manufactured in multiple ways, as stated above. The nanoparticles of Titanium Carbide have various important uses due to their unique properties. More importantly, they are used as a coating material for drills, tools, saw blades, etc.

Recent Posts

-

Advanced Materials for Unmanned Aerial Vehicle (UAV) Protection Against Laser

Consider a UAV on a critical mission, rendered inoperative by a sudden laser attack. With the increa …26th Jul 2024 -

Simulation and Modeling of Material Properties

Our world is composed of a dazzling array of materials, each with its own unique properties that dic …19th Jul 2024 -

Advanced Coatings for Superior Corrosion and Wear Resistance

Corrosion and wear pose significant challenges across various industries, leading to substantial eco …12th Jul 2024