Lithium-Ion Batteries: How They Work, Where They Are Used, Advantages & Disadvantages

At present, lithium batteries are the most widespread types of energy accumulator in the world and are used in a huge diversity of implementations, including smartphones, notebooks, tablets, and many other devices that require a reliable battery and with a large performance. That is why lithium batteries are the most chosen accumulator among manufacturers and developers worldwide, precisely because of their energy efficiency, without a doubt, it is the most important variable when it comes to portable devices that require a stable power supply.

Although other types of batteries composed of different materials are already under study and development, there is still a long time left before the lithium battery is replaced by an equally reliable and efficient battery. In this article, we will generally see what lithium is, what lithium ions are, and then what lithium-ion batteries are. Furthermore we will see the advantages (and disadvantages) of lithium ions compared to other batteries currently on the market, and we will analyze the details of lithium-ion solutions for data center batteries and UPS (Uninterruptible Power Supply) and how lithium-ion batteries are the optimal solution for powering data centers, UPS and the IoT (Internet of things). First of all, let’s see what lithium is and its origin.

Origin of Lithium

Due to its high reactivity in nature, lithium only occurs bound in the form of salts. The world's lightest metal is being mined all over the world: in Tibet, Australia, Nevada - but above all in South America. Prerequisite for the presence of lithium is volcanic activity - not every salt contains lithium. A good 70% of the lithium deposits are located in the South American salt lakes of Bolivia, Argentina, and Chile.

In Bolivia, Salar de Uyuni is the largest salt lake in the world. The lake, which also contains lithium, stretches over approximately 10,000 square kilometers. The lithium-dried reserves are even mined under harsh conditions and then removed by trucks. In the future, the poor country wants to massively upgrade in order to benefit more from the lithium boom - thanks to electric cars.

Moreover, Huge lithium reserves are located in northern Chile. In Salar de Atacama, located in the Atacama Desert, the lithium brine from the lake is first pumped to the surface by pumps. The brine is still wet - but for further processing, the lithium has to be dry. Therefore, it is pumped into "solar ponds" and dried there by the sun. It crystallizes and reaches up to 60% higher concentration in this bath after 18 to 24 months. Lithium is the namesake and the basic element of lithium-ion batteries. However, it is not incorporated as a pure metal in the rechargeable batteries as a cathode, but in the form of a lithium metal oxide.

It is to be noted that 27% of global lithium production is used in battery manufacturing. Lithium is used in various forms in many industries - even as a drug in the treatment of depression. At 28%, most of the world's lithium is used in the ceramics and glass industry. But with 27%, the battery and battery production is already in second place. Future needs are huge in the face of electric cars.

What are Lithium-ion batteries?

Batteries are used to convert chemical energy into electrical energy through a redox reaction (i.e. "redox", reduction and oxidation), or a chemical reaction in which electrons are transferred from one chemical species to another. This transfer is then used to supply external loads.

One of the developments that the battery world has taken today is lithium-ion batteries, or simply lithium batteries. The life, durability, and efficiency of lithium batteries is often higher than that of ordinary batteries, and given that for anyone who uses a smartphone, the duration of the charge is very important, We often associate the quality of the mobile phone, smartphone or iPad with the quality of its battery.

So what are these lithium-ion batteries?

These are rechargeable batteries, traditionally used in the field of electronics applied to communication services. They are characterized by their lightness and compactness and, precisely, by the possibility of being recharged quickly, unlike their nickel (NiCd or NiMH) colleagues, although they present some criticalities both due to the progressive consumption to which they are subjected and in the case in which they are not used for a certain period of time.

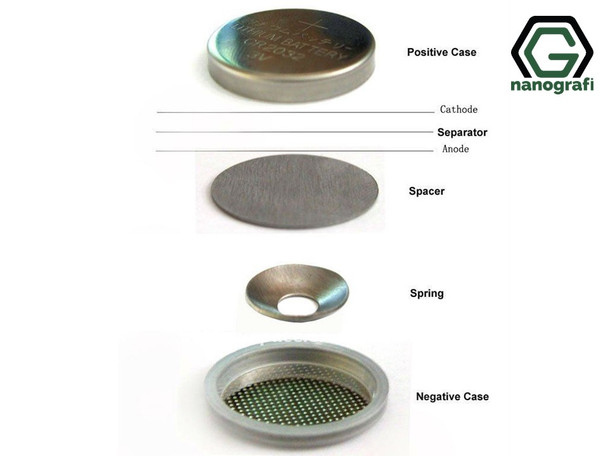

Components of Lithium-Ion Batteries

Each lithium-ion cell has four basic components. The four components of each lithium-ion cell are given below:

1. Cathode: positive lithium metal oxide electrode (Click for Nanografi’s Cathode materials)

2. Anode: negative graphite electrode (Click for Nanografi’s Anode materials)

3. Separator

4. Electrolyte

A lithium-ion battery is built up in layers from one or more battery cells. The two central layers of a lithium-ion cell are the negative graphite electrode and the positive lithium metal oxide electrode. There is also a separator that separates both layers and a nonaqueous but liquid electrolyte that conducts the ions.

The cathode is located to dissipate the current on a good electrical conductivity aluminum foil, the anode on a copper foil. During charging, positive and negative poles are connected by a metal contact and an electrical voltage is applied. As a result, positive lithium ions now dissolve out of the lithium metal oxide and migrate to the anode. At the same time, negative electrons migrate from the cathode via the metal contact to the negative electrode and compensate for the positive charge of the lithium ions again. When unloading, the process is reversed.

The separator is a sandwich of layered plastics. To prevent the anode and cathode from touching, causing a short circuit, they are separated by a porous plastic sandwich: the separator. This must be so permeable that the tiny positive lithium ions can migrate to the anode when charging the battery. The separator usually consists of a mixture of permeable plastics, which the producers heat, mix and dry.

A functional battery cell is only created when all components are put together. The anode and cathode are separated by the separator, as mentioned before. Since the foils are so thin, the producers apply a metal strip to them with high-frequency ultrasound. These are more stable and therefore better suited to attach the terminals for the electrical voltage.

The almost finished cell is built into a moisture-impermeable envelope. These can be prismatic or round hard cases, but most manufacturers now use pouch-bag cells which are also called "coffee-bag cells" for their appearance (Click for Nanografi's Pouch Cell Materials). These shells are usually made of a flexible aluminum foil, in which the cell of cathode, anode, and separator is welded. The electrolyte from solvents and the conductive salt is also added to the cell here. Only now can the lithium ions move freely from one electrode to the other electrode. In testing laboratories, manufacturers now check the voltage curve by alternately discharging and recharging.

Working of Lithium-ion Batteries

The operation (i.e. the charging and discharging) of lithium batteries, whose structure is composed of a positive electrode (lithium cathode) connected to a negative electrode (consisting of a carbon anode), is realized through chemical reactions which allow to discharge and recharge the energy.

Despite false myths, originating from the first types of rechargeable nickel-cadmium batteries, which need to run out completely before they can be properly recharged, today's lithium batteries have fewer problems in the event of partial recharging: they do not lose, in fact, the ability to store currently if they are only partially recharged, thus not suffering from the so-called "memory effect", a problem instead present in nickel batteries.

There is a technology that plays a key role in the functioning of Data Centers and more, which has remained substantially similar to itself in the last 40 years due to the combination of a series of factors (technological and otherwise). This is known as radical transformation. We are talking about UPS and, in particular, about the way in which electricity is stored, which in all these decades has seen the predominance of lead batteries.

Something, however, is changing in the world of batteries, due to the important investments that first of all affect devices such as smartphones and electric cars, investments that will also have an impact on UPS. This, in turn, are called upon to respond to new requests from end-users. Among these are:

- An increase in the availability of energy storage and the ability to predict failures

- A reduced footprint and weight of the UPS to allow more efficient and flexible use of space

- Greater durability and reduced maintenance costs

According to Schneider Electric, UPSs equipped with lithium-ion (Li-ion) batteries have excellent chances of being able to respond effectively to all these challenges.

First, lithium-ion batteries provide more energy than lead-acid batteries (VRLA) with higher power density. As a result, UPSs built with lithium-ion batteries occupy only about a third of the space or less of a VRLA-based solution that provides the same power. This small footprint translates into a reduction in cooling requirements and a weight reduction of at least two thirds. This means that customers have more flexibility on where to install UPS systems, without having to make expensive changes to buildings.

Lithium-ion batteries can also withstand a wider temperature range than VRLA batteries. The general rule is that the VRLA battery life is reduced by half for every 10 ° C increase over 25 °C. Conversely, lithium-ion batteries when used at low discharge speeds are much less sensitive to fluctuations than temperature and can accept spikes with almost no effect on battery life. In the case of UPS, where the batteries have to do with very short operating times and high discharge speeds, there is a certain degree of sensitivity to temperatures, which is in any case lower than lead batteries.

A third advantage is that lithium-ion batteries are always equipped with sophisticated battery monitoring systems (BMS) which provide a clear picture of the battery's operating time and health. In contrast, VRLA batteries essentially rely on chemistry which makes it difficult to accurately predict the time of the end of life.

Then there is one last, fundamental benefit of lithium-ion batteries, that is their greater life expectancy. In theory, VRLA batteries used in UPS systems have a life expectancy of 10 years. However, due to the difficulty of determining the real-life expectancy, in practice most customers replace them after 5 or 6 years. On the contrary, lithium-ion batteries can last for more than 10 years, reducing the costs of battery replacement, as well as the risk of downtime or interruptions.

Alongside the advantages, there are obviously a whole series of critical issues that can be further improved. Also because the requirements and needs of the UPS are very different from those of an electric car, car batteries are designed to store a lot of energy so that the car can travel as many kilometers as possible.

Furthermore, for a UPS, customers are certainly not interested in a device that can turn on and off thousands of times, since a UPS only works occasionally. Rather, the need is to have one that is highly reliable and safe, with a long life expectancy. Secondly, what really makes the difference is having a battery that can provide lower TCO (Total Cost of Ownership) than VRLA batteries. Lithium-ion batteries are already competitive on this front. Of course, they could cost more at the time of purchase, but this aspect is offset by longer useful life. Not only the footprint is decidedly smaller, thus reducing both space and cooling requirements, thus offering further cost savings.

Why choose Lithium ions

In addition to consumer devices, lithium-ion batteries are playing an increasingly important role in the Data Center. The fundamental reason is that the advent of the Internet of Things (IoT) means that a myriad of processing and network devices are now installed in areas outside the traditional perimeter of the data center: branches and home offices, sales outlets, industrial sites, even outdoor areas such as wind and solar plants.

Obviously, the multiplication and distribution of IT increase the risks of disruptions, in the event that a member of the chain experience problems, in particular with respect to the fundamental source of information technology functioning: the current electricity. To take shelter, organizations must equip themselves with special uninterruptible power supplies (UPS) capable of powering the devices in the event such problems arise.

Advantages of lithium-ion batteries (for UPS)

The good news is that UPSs are now increasingly up to the task, offering customers an important technological alternative as well. In fact, historically the UPS have relied solely on lead batteries (VRLA), but now an alternative is beginning to appear, and it is that of lithium ions (Li-On): these are about 30% lighter than batteries of those VRLA and significantly smaller. A feature that involves at least two types of benefits: first of all, the possibility of storing more energy in the same space and the same amount of electricity in a smaller space.

Furthermore, lithium-ion batteries can withstand temperature fluctuations better than VRLA batteries, making them more suitable for places with higher temperatures. In particular, there are a number of sectors that could be particularly advantaged by the use of Li-ion UPSs.

The difference compared to other types of batteries (APC Smart-UPS, VRLA, etc.)

The point is that, while high-value applications like medical diagnostic equipment and factory process controllers are probably already protected by UPSs, Li-ion can extend protection from electrical outages to this type of "minor" services. In fact, so far, the lack of adequate space has prevented the installation of continuity units in these circumstances, which may have played a crucial role, as we have seen.

Furthermore, the longer life of lithium-ion batteries, which effectively eliminates the need for maintenance, represents an additional incentive to install. Obviously, before making a purchase of any kind, companies must ensure that they put a UPS in their home in line with safety regulations.

Which batteries to choose for the Data Center: Lithium-ion batteries or VRLA?

Li-Ion Battery solutions help reduce the total cost of ownership thanks to simplified battery maintenance. Lithium-ion solutions have several advantages over traditional lead-acid batteries, but their use for UPSs is relatively recent. In contrast, lead-acid valve batteries remain the main energy storage technology.

To understand how to best use the two technologies, you can compare the two technologies for use in static UPS applications. Due to the comparison of the ten-year total cost of ownership (TCO) for both solutions, the adoption of lithium-ion batteries proves to be a winner with a TCO 39% lower than that of VRLA batteries even if the initial capital cost is greater, with a return on the initial investment of around 4 years.

Advantages, Disadvantages, and Limitations of Lithium Batteries

Since lithium is, in fact, a flammable metal, exposure of the battery (and therefore of the device) to high temperatures makes it particularly prone to explosions, but there is nothing to worry about if you remain careful.

Sun and heat can be considered the worst enemies of lithium accumulators because they consistently contribute to accelerating their natural aging. Therefore, if leaving a battery attached to its charger for too long a period in itself does not present any particular problems with its recharging, the same cannot be said with regard to any power surges or short circuits, situations that can seriously undermine them.

It should be considered that lithium-ion batteries can be used even months apart; while losing part of their potential, excessive non-use does not lead to an excessive loss of considerable charge, whereas traditional batteries, if not used for the same period of time, lose up to 50% of their charge.

The cost of lithium-ion batteries

Given the numerous advantages already listed, it should be noted that currently, the cost of lithium batteries is decidedly higher than traditional ones. If a comparison is made with lead batteries, it can be verified that a lithium battery, at the same capacity, today costs about 4 times more but they are recommended since you don’t need to change it too often like other batteries which eventually lead to higher costs.

Therefore, lithium batteries are recommended in situations where use is occasional, with low power loads, (e.g. tablets, cell phones), it is assumed that in the future, due to the large increase in the production of lithium hydroxide (which will lead to a constant and continuous fall in prices) lithium batteries will be increasingly present in our daily habits.

Lithium-ion batteries: use for UPS and Data Center

As we have told on several occasions, lithium-ion (Li-ion) batteries are capable of causing a radical change in the field of UPS (UPS), mainly due to their longer duration, as well as of their weight and small footprint compared to devices operating with the classic lead batteries. But what are the concrete impacts in small and medium-sized data centers, which are often widespread in businesses?

The impact can be very important. First of all, there is the theme of the significant space occupied by lead batteries, which for this reason are not placed inside the IT White Room. In addition, many organizations in recent years have increased the temperature of their data center server rooms to save on cooling costs, in line with green and energy-saving indications from multiple fronts. The problem is that while IT equipment and UPSs can tolerate higher temperatures, VRLA batteries, on the other hand, tend to age faster. For all these reasons, companies tend to create dedicated rooms specifically to house VRLA batteries.

Lithium-ion technology has everything to dramatically reduce the size of these rooms since lithium-ion batteries have a much higher energy density. For data center designers, this translates into an increase in the footprint available for the IT space, while at the same time reducing the cooling requirements, saving both capital and current operating costs. In addition, in some cases lithium-ion batteries can be installed inside the white room, along with the IT infrastructure and the UPS. One possibility is easy to understand, which is particularly noticeable for small and medium-sized data centers.

Similarly, companies that use scalable and adaptable integrated data center architectures could further benefit from Li-ion technology. With such architectures, IT racks, power and cooling components are built and tested as part of an integrated data center solution that can then be expanded if necessary over time. Lithium-ion batteries are able to make these integrated “pods” even more efficient in terms of space and energy than existing ones, offering the same advantages associated with the proximity of IT to the UPS/battery combination.

General Tips for using Lithium-Ion Batteries

1. Completely discharging a Li-Ion battery is harmful to the battery. Whenever this happens, a part of the battery dies: it loses its ability to resume charge.

2. Never store your empty batteries, chances are you will find them dead or with near-zero capacity.

3. Li-ion batteries have a limited life, they degrade over time even if they are not used. Use them as soon as you buy them. Do not buy them to store them, use them later or have them in advance.

4. A Li-Ion battery cannot be restored, by over-charging (by boosting), heating, etc. It is necessary to buy a new one. They are degraded all the time, ineluctably, the cells gradually lose their capacity to store and give back the electricity then they end up dying.

5. Fast car chargers always damage your battery because they put too much energy, too quickly to your battery (voltage). The original charger or the slow charge on USB is better. Fast chargers provide a high charging voltage which degrades the long-term charging capacity. The general idea is that "the slower the charge, the longer the battery will serve you".

6. The life of Li-Ion batteries is short. You should not expect more than 2 or 3 years before a loss of more than 50% of the initial duration. This is due to an internal oxidation phenomenon and there is no way to remedy or prevent it.

7. The ideal charge for storing batteries is 40%. The ideal temperature should be between 0 °C and 20°.

8. Li-Ion batteries better withstand frequent charges and partial discharges than full charge/discharge cycles.

Thus, Lithium-ion batteries offer a plethora of advantages as compared to other types. In addition to reducing space and energy requirements, Li-ion batteries last twice as long and require less maintenance than the VRLA. They are also equipped with advanced battery monitoring systems (BMS), which allow IT, groups, to access in a simple and remote way a reliable measure of the "state of health" and the "state of charge" of the batteries. This inevitably translates into a lower need for maintenance.

Recent Posts

-

Advanced Materials for Unmanned Aerial Vehicle (UAV) Protection Against Laser

Consider a UAV on a critical mission, rendered inoperative by a sudden laser attack. With the increa …26th Jul 2024 -

Simulation and Modeling of Material Properties

Our world is composed of a dazzling array of materials, each with its own unique properties that dic …19th Jul 2024 -

Advanced Coatings for Superior Corrosion and Wear Resistance

Corrosion and wear pose significant challenges across various industries, leading to substantial eco …12th Jul 2024