Explained Hydrogels and Applications - Nanografi Blog

Hydrogels are crosslinked polymer networks. The polymer structure of hydrogels exhibits great absorption capacity, swelling and shrinking behavior upon environmental changes and biocompatibility. Through different preparation methods and polymeric components, hydrogels can acquire different responsive behaviors. Hydrogels can be responsive to pH, temperature, solvent composition, enzymes, electric fields, and light.

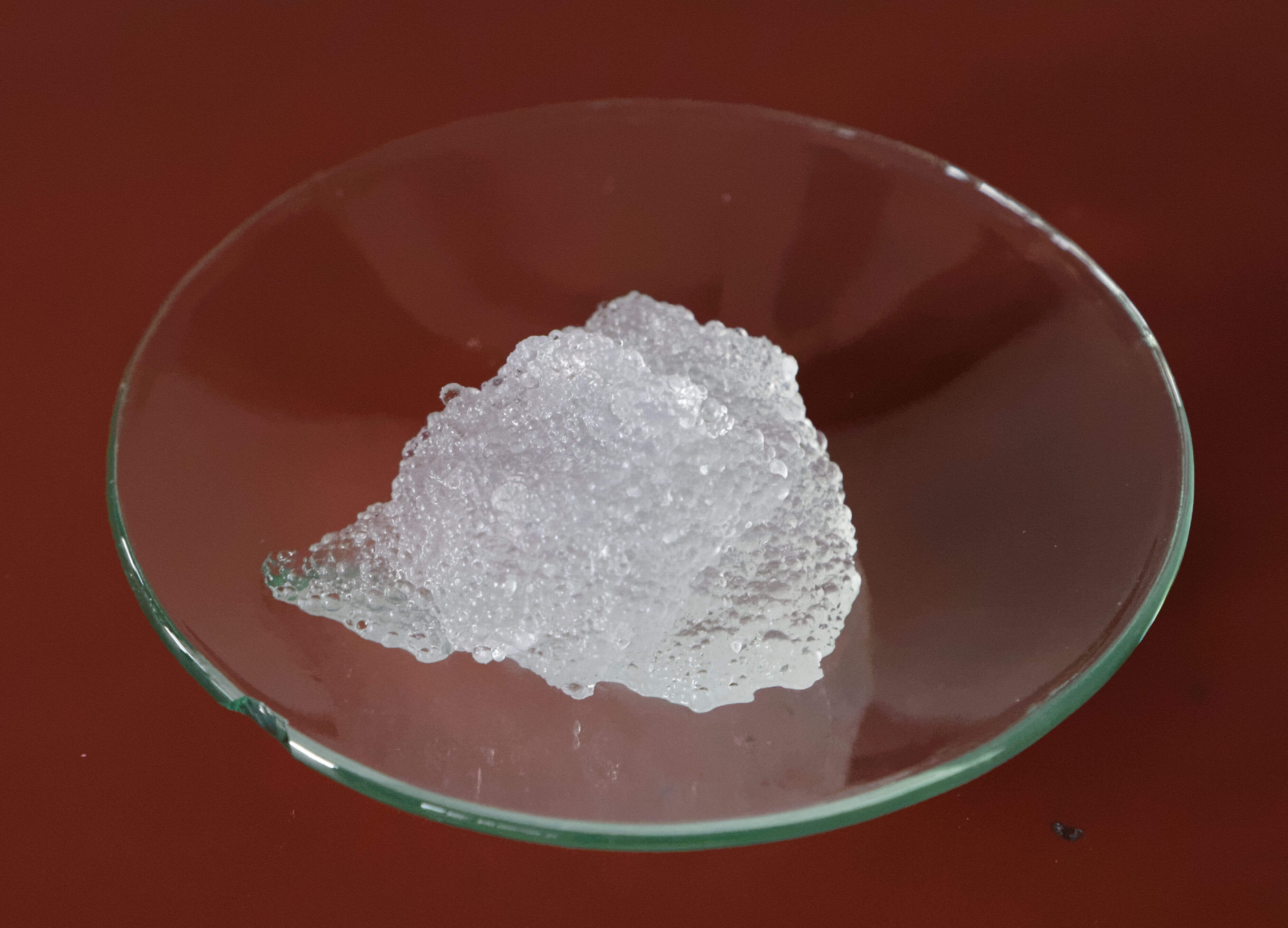

Click Image to Check Hydrogel Applications

Over the past decades, science has come up with a wide array of peculiar materials that offered solutions to the existing problems all while creating new ones. An exciting example of these peculiar materials is hydrogels. Hydrogels are crosslinked polymer networks with an excellent absorption capacity. Hydrogels exhibit the properties of elastic solids with deformability and softness. The high water content in hydrogels leads to liquid-like attributes of hydrogels, including permeability to a wide range of chemical and biological molecules, and transparency to optical and acoustic waves. Hydrogels show great swelling and deswelling behaviors in response to the changes in environmental conditions such as pH, temperature, solvent composition, enzymes, electric fields, and light. The properties of hydrogels can be manipulated through different preparation methods and using different types of polymers in the network structure. The polymer network of hydrogels can be hydrophilic or hydrophobic depending on the types of polymers in the network. Most importantly, hydrogels are biocompatible materials since they are composed of polymer chains. The responsive nature and biocompatibility of hydrogel to environmental changes of hydrogels are useful in many different application areas such as drug delivery systems, tissue engineering, optics, diagnostics, and imaging.

Hydrogels are classified based on various different features. The parameters for hydrogel classification are based on size, physical structure, ion charge, structural and mechanical properties, synthesis route, types of bonds in their structure.

There are three different types of hydrogel based on their size; macrogels, microgels, and nanogels. Due to their smaller sizes, micro and nanogels have advantages over the macrogels. According to the synthesis route, hydrogels are classified into homopolymers, copolymers, and multipolymers. Homopolymer hydrogels are prepared from only one type of hydrophilic monomer; copolymer hydrogels comprise two types of monomers, and multipolymer hydrogels are prepared from three or more monomers. Based on the physical structures of networks, hydrogels can be amorphous, semi-crystalline, hydrogels with hydrogen-bond structure, supermolecules, and hydrocolloid aggregates. Hydrogels can be anionic, cationic, neutral, and ampholitic depending on the ionic charges in their polymer network. Owing to their synthesis route, hydrogels can be categorized as chemically or physically synthesized hydrogels.

Preparation of Hydrogels

Several different methods for hydrogel preparation have been investigated over the years. The most common techniques are physical cross-linking, chemical cross-linking and irradiation polymerization. Different production methods create a wide variety of hydrogels with different compositions, sizes, and morphologies. Moreover, the use of different functional initiators or micro initiators enables the incorporation of different functional groups to the hydrogel structure.

Physical Cross-linking

The physical cross-linking method is an attractive preparation method since it is a relatively easy route requiring no cross-linking agents. The lack of need for cross-linking agents prevents the undesired material accumulation in the hydrogel structure and the need to remove them prior to use. Adjustments to the selection of hydrocolloid, concentration, and pH of the preparation environment lead to a variety of hydrogel properties. The ease and convenience of physical cross-linking have attracted great attention. However, it is important to note that the hydrogels prepared by physical cross-linking are rather fragile since polymers in their structure are bonded with weak interactions such as hydrogen bonds, hydrophobic or ionic interactions. There are different methods for physical cross-linking such as heating or cooling a polymer solution, ionic interactions, complex coacervation, hydrogen bonding, maturation or aggregation resulted from heat, and freeze-thaw cycles.

Chemical Cross-Linking

Another widely used method for hydrogel production is chemical cross-linking. The chemical cross-linking occurs in the presence of a cross-linker and involves the covalent bonding of polymer chains during the polymerization of monomers or cross-linking of polymer precursors. Cross-linking of natural and synthetic polymers can be attained by the reaction of some functional groups such as hydroxyl, carboxylic, and amine groups with cross-linkers such as aldehydes, glutaraldehyde, epichlorohydrin, adipic acid dihydrazide, and polyaldehydes.

Polymerization by Irradiation

Hydrogels are also prepared through polymerization by the irradiation method. High energy irradiation like gamma and electron beam is applied to the unsaturated polymer solution to obtain radicals on the polymers. The recombination of these macroradicals results in the formation of covalent bonds, and finally, a cross-linked structure is formed.

Other Preparation Methods

In addition to the above-mentioned methods, hydrogels can be prepared through grafting, condensation and enzymatic reactions. Grafting involves the polymerization of monomers onto a preformed polymer chain. This polymerization can be initiated by chemical compounds or by irradiation. The condensation reaction method is generally applied for the preparation of hydrogels containing hydroxyl groups/amines with carboxylic acids or their derivatives.

What are the Different Types of Hydrogels?

The unique swelling mechanism of hydrogels can be stimulated by various different external effects including pH, temperature, solvent composition, enzymes, electric fields, and light. Stimulation by one or more of these effects trigger a chemical mechanism leading to a significant volume change. Thanks to this swelling, hydrogels can absorb a great amount of water or other biological fluids.

pH-sensitive Hydrogels

The pH change in their environment induces pH-sensitive hydrogels to undergo a sudden volume change. The pH-sensitive hydrogels contain ionizable acidic and basic groups in their protein network. A pH change in the environment causes proton intake or release from the acidic and basic sites of the hydrogel. This proton movement crates an ion gradient in the solution and most importantly an osmotic pressure on the hydrogel structure. Osmotic pressure leads to the desired volume change. The swelling continuous until the osmotic pressure on the hydrogel is balanced. Anionic hydrogels swell at high pH levels while cationic hydrogels swell at low pH levels. pH-induced swelling and deswelling are reversible and repeatable. Swelling and shrinking characteristics of the hydrogels can be tailored or controlled by incorporating monomers or anionic polymers such as divinyl ether, maleic anhydride, 2-acrylamido-2-methyl-1-propane sulfonic acid (AMPS), poly (ethylene-co- maleic anhydride), poly (acrylic acid), poly (maleic anhydride), sulfonated poly (ethylene glycol), and pentasan polysulfate, etc. into polymeric networks.

Temperature-sensitive Hydrogels

Temperature-sensitive hydrogels are the most studied hydrogel structures. There are three types of temperature-sensitive hydrogels; positive temperature-sensitive hydrogels, negative temperature-sensitive hydrogels, and thermally reversible hydrogels. Temperature-sensitive hydrogels contain both hydrophobic and hydrophilic groups in their own network. They swell or shrink either at lower critical solution temperature (LCST) or at the upper critical solution temperature (UCST). These critical temperatures can be manipulated by altering the ratio of hydrophobic to hydrophilic constituents of the polymers. At temperatures lower than LCST the hydrogen bonds between the water molecules and hydrophilic parts of the hydrogel are stronger leading to a better dissolution of the polymer in the water. However, when the temperature rises, hydrogen bonds become weaker and the interaction between hydrophobic segments of the polymer chain gets stronger, leading to hydrogel shrinkage due to the association of the polymer chain through hydrophobic interactions. The most popular temperature-sensitive hydrogels are based on poly (N- isopropyl acrylamide). This hydrogel exhibits a transition temperature of around 33 °C. At this temperature, the hydrogel undergoes a sudden shrinkage. Another well-known temperature-sensitive hydrogel is poly (N-isopropyl acrylamide) which is abbreviated as PNIPAAm. This hydrogel has a sharp hydrophilic-hydrophobic transition in aqueous solution at 32 °C.

Light-sensitive Hydrogels

Light-sensitive hydrogels can be stimulated by either UV-light or visible light. Some UV light-sensitive hydrogels contain leoco cyanide which is ionized under UV radiation. Upon the ionization of leoco cyanide, osmotic pressure is created on the hydrogel. Just like pH-sensitive hydrogels, this osmotic pressure is balanced by the swelling of the hydrogel network. Other light-sensitive hydrogels are usually based on temperature-sensitive hydrogels. Light-sensitive hydrogels contain chromophores which increase the temperature of the environment upon absorbing and then emitting the light. From this point on, light-sensitive hydrogels act just like temperature-sensitive hydrogels.

Electro-sensitive Hydrogels

Electro-sensitive hydrogels swell or shrink under an applied electric field. These hydrogels swelling mechanism is similar to pH-sensitive hydrogels. However, the electric field can manipulate the ions in the solution in peculiar ways and direct the hydrogel swelling as desired. For example, through the manipulation of ion movement one side of the hydrogel can swell while the other side shrinks. So far, many synthetic polymers such as poly (vinyl alcohol)/poly (sodium acrylate-co-sodium maleate), acrylic acid/vinyl sulfonic acid copolymer and sulfonated polystyrene have been employed for the synthesis of electrosensitive hydrogels.

Mechanically-sensitive Hydrogels

Mechanically-sensitive hydrogels are synthesized mainly by using surfactants. These hydrogels contain microstructures consisting of rigid nanowire-like aggregate. These microstructures are the basis of mechanically-sensitive behavior.

Enzyme Responsive Hydrogels

Some groups of hydrogels undergo a phase transition when they are triggered by a catalyst or enzyme molecule. Most research has focused on the protease- and glycosidase-responsive polymer hydrogels over the past five years.

What is the Importance of Hydrogels?

Hydrogels are promising novel materials that have been developed over the last decades. They exhibit the behaviors of both solid and liquid-like systems resulting in unique properties. The importance of hydrogels comes from their excellent swelling/shrinking properties, biocompatibility, and responsive nature to environmental changes. Hydrogels swell or shrink as a response to different stimuli such as pH, temperature, solvent composition, enzymes, electric fields, and light. This responsive behavior of hydrogels can be manipulated through different preparation methods and using different components in their polymer network. Due to the active nature of polymers, it is also possible to integrate desired materials such as inorganic compounds or drugs into the hydrogel structure. These promising properties of hydrogels have the potential to be exploited by researchers and provide solutions to various different problems.

Click Image to Find Out About Nanocellulose

References

- 1.Mahinroosta, M., Farsangi, Z. J., Allahverdi, A., & Shakoori, Z. (2018). Hydrogels as intelligent materials: A brief review of synthesis, properties and applications. Materials today chemistry, 8, 42-55.

- 2.Varaprasad, K., Raghavendra, G. M., Jayaramudu, T., Yallapu, M. M., & Sadiku, R. (2017). A mini review on hydrogels classification and recent developments in miscellaneous applications. Materials Science and Engineering: C, 79, 958-971.

- 3.Sahua, N. K., Gilsb, P. S., Rayb, D., & Sahoo, P. K. (2012). ISSN 2277–7164 Hydrogels: A Review.

Recent Posts

-

Advanced Materials for Unmanned Aerial Vehicle (UAV) Protection Against Laser

Consider a UAV on a critical mission, rendered inoperative by a sudden laser attack. With the increa …26th Jul 2024 -

Simulation and Modeling of Material Properties

Our world is composed of a dazzling array of materials, each with its own unique properties that dic …19th Jul 2024 -

Advanced Coatings for Superior Corrosion and Wear Resistance

Corrosion and wear pose significant challenges across various industries, leading to substantial eco …12th Jul 2024