Explained: Buckypapers

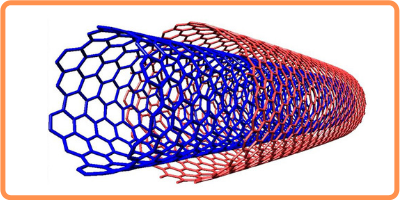

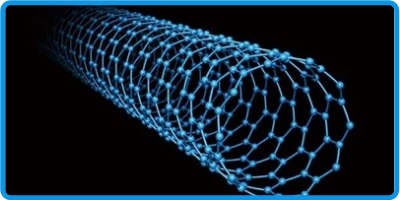

Among the carbon nanoparticles which are being used as nanofillers, carbon nanotubes (CNTs) have superior thermal, mechanical, and electrical properties that are determined by both theoretically and experimentally. Thus, because of their outstanding properties, they are used in many applications. However, the size of CNTs is very small having an average diameter of 1nm and few micrometer widths. Therefore, it is nearly impossible for CNTs to be used in industrial applications. In order to overcome this problem, different techniques have been used to fabricate CNTs to macroscale networks, which are also named as buckypaper. Buckypaper (BP) is a thin sheet of aggregation or network of CNTs at macroscopic levels.

Figure 1: Optical image of a multi-wall carbon nanotube (MWCNT) buckypaper [1].

Buckypapers are thin films of randomly entangled CNTs, which form porous networks mainly due to van der Waals interactions. Because of van der Waals interactions, CNTs have tendency to form aggregates and a cohesive buckypaper. Buckypapers are produced by simple methods, and they are the first macroscopic arrangements fabricated from CNTs and fullerenes. After the discovery of buckypapers, the mechanical, electrical, chemical, and thermal properties of BPs have been widely studied. It is found that buckypaper can be extremely elastic and mechanically strong. The attractive van der Waals interactions become less effective if the diameter of MWCNTs and this causes buckypapers to have poor cohesiveness and low tensile strength. However, the tensile strength can be increased to some extent with the addition of polymer or the functionalization of MWCNTs. Longer, pure, narrow-walled CNT results in mechanically strong buckypaper with high tensile strength values. Buckypaper is such a fine material that has an approximate size of 1/50000 th of the diameter of a human hair. It would be a mistake to consider that although it is such a fine material, CNTs have atomic bonds so strong which are twice harder in comparison with diamond. The nanotube quality, suspension concentration, dispersion quality, filtering techniques, and additional filtering approaches such as magnetic alignment of nanotubes are extremely important parameters for the properties of buckypapers, and these parameters should be taken into consideration during the buckypaper fabrication. Generally, extra-pure, narrower, longer CNTs enhance buckypapers’ tensile strength. Apart from their mechanical properties, buckypapers are highly thermally conductive. Also, BPs have good electrical conductivity, they can conduct electricity like copper or silicon. In addition, buckypaper has low optical reflectivity.

Click Image to Read About Carbon Nanotubes

Synthesis of Buckypapers

Buckypapers can be prepared by several simple methods. These various techniques are developed to produce different types of BP materials. Some techniques are used to produce networks with high mechanical strength, while some methods focus on thermal, electrical, and optical properties. In buckypaper formation, two main steps are involved, that is, dispersion of CNTs nanoparticles in suitable solvents and filtration process. Firstly, the CNTs are purified and then dispersed in aqueous medium to obtain a suspension. The suspension is filtered through a porous membrane, on the surface of which CNTs are captured and form optically dense buckypaper membrane. The buckypaper is dried and then peeled off from the porous support. To arrange the individual CNTs, the filtration process can be carried out under a magnetic field due to which the conductivity increases along the direction of alignments.

Figure 2: Photograph of a free-standing Buckypaper [2].

Typically, CNTs are contaminated with carbonaceous materials such as fullerene, amorphous carbon, graphitic nanoparticles, and other metallic nanoparticles. The dispersion and purification in buckypapers processing step affect both structure and properties of buckypaper. The following steps can be used for CNT dispersion;

(i)the CNT surface is functionalized covalently to enhance the chemical compatibility using suitable solvent;

(ii)the use of polymer, surfactant, or DNA molecules;

(iii)the use of mechanical treatment such as shear mixing and ultrasonication.

First Buckypaper Fabrication

First buckypaper synthesis was conducted in 1998 by a scientist named Smalley. At first, the CNTs were functionalized with Triton-X 100 surfactant and then ultrasonicated to break up the larger ropes or CNTs bundle. The resulting CNTs dispersed in aqueous solution were filtered through a porous membrane of unspecified pore size through vacuum filtration. The paper was washed with methanol to remove the surfactant and then peeled off from the membrane. By applying these steps, buckypaper was obtained.

Methods for Buckypaper manufacturing

Drop drying techniques for single-walled carbon nanotube sheets

In this method, SWCNTs are mixed with water and a surfactant and then dropped onto a glass slide. After, the drops are dried at ambient temperature and the nanotubes are self-assembled into a crust. This technique is assumed to make optically transparent, thin (100 nm), and conductive sheets or films and coatings. In order to make the films conductive, it is essential to remove the surfactant by boiling the crust or increasing the amount of SWCNTs in polymer–SWCNTs blend to enhance the interaction between nanotube layers.

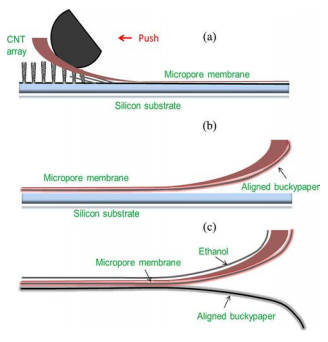

Domino pushing technique for highly oriented CNTs buckypapers

This method enhances the electrical and thermal properties of buckypaper. In this technique, MWCNTs are used in contrast to SWCNTs. Chemical vapor deposition technique (CVD) is used to grow forests or arrays of vertical MWCNTs on silicon substrate having diameter of 10 cm. On the top surface of arrays of MWCNTs, a microporous membrane is placed and pressed at constant pressure. This step should be repeated multiple times, hence MWCNTs are aligned with the help of van der Waals interactions and are flattened to create nanotubes network or buckypaper. After the formation of buckypapers, the silicon substrate is removed and then the paper is peeled off from the microporous membrane by soaking in ethanol.

Figure 3: Domino pushing techniques (a) pushing, (b) aligned buckypaper, and (c) buckypaper peel-off [3].

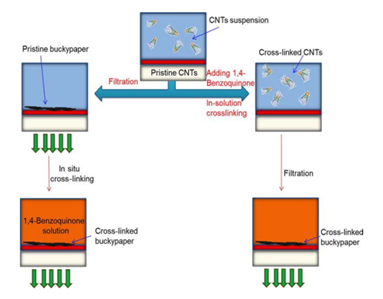

In situ intertube cross-linking buckypaper formation

In situ cross-linking, the as-formed buckypaper is washed with water and retained in the filter paper. Then, preconditioned solution of 1,4-benzoquinone by dissolving 1,4-benzoquinone in water with sonication for 1 h. The situ cross-linking is directed by infiltrating the solution of 1,4-benzoquinone over the as-prepared CNTs buckypaper for several times. For the cross-linking, it is necessary to produce the air bubbles in the filtration system during filtration process. After that, the in situ intertube cross-linked buckypaper is peeled off the filter and dried. This technique helps to increase the current transfer abilities and intertube stressing of the buckypaper network by cross-linking the CNT junctions. Therefore, it enhances both electrical and mechanical properties of the buckypaper and suggests these multifunctional materials for new kind of engineering applications.

Figure 4: In situ and in-solution techniques for CNTs cross-linked buckypaper formation [4].

Application Areas of Buckypaper

Possible uses for buckypaper are still being researched, but their practical applications are already interesting. There are some applications of buckypaper in industry or in other areas listed below.

- Buckypapers are used in fire-protection by covering material with a thin layer of buckypaper significantly improves its fire resistance due to the efficient reflection of heat by the dense, compact layer of carbon nanotubes or carbon fibers.

- If a compound is exposed to an electric charge in an application, buckypaper could be used to illuminate computer and television screens. It could be more energy-efficient, lighter, and could allow for a more uniform level of brightness than current cathode ray tube (CRT) and liquid crystal display (LCD) technology.

- Since individual carbon nanotubes are one of the most thermally conductive materials known, buckypapers can be used in the construction of heat sinks that would allow computers and other electronic equipments to disperse heat more efficiently than is currently possible now.

- Films also could protect electronic circuits and devices within airplanes from electromagnetic interference, which can damage equipment and alter settings. Similarly, such films could allow military aircraft to shield their electromagnetic "signatures", which can be detected via radar.

- Buckypaper could act as a filter membrane to trap microparticles in air or fluid since the nanotubes in buckypaper are insoluble and can be functionalized with a variety of functional groups, so they can selectively remove compounds or can act as a sensor.

- Buckypaper can be used to grow biological tissue, such as nerve cells, and they can be electrified or functionalized to encourage growth of specific types of cells.

- Buckypapers can be employed as electrode materials for supercapacitors lithium-ion batteries , and vanadium redox flow batteries due to their high electrical conductivity.

- Buckypapers are capable of use in artificial muscles because the Poisson’s ratio of carbon nanotube buckypaper can be controlled and exhibits auxetic behavior.

- Buckypaper composites may be served as an effective armor plating material if they are produced in high enough quantities and at an economically applicable price.

Read More About Doublewalled Carbon Nanotubes Read More About Singlewalled Carbon Nanotubes

Conclusion

The buckypaper has particular properties such as strength, lightweight, durability, and high electric. These materials add new functionalities to other composites materials such as improved electrical conductivity, rheological control properties, enhanced mechanical properties, thermal properties, and flame retardancy. Although buckypaper has some outstanding properties, it is a rather new material and more research should be done in order to enhance the properties and moderate the disadvantages. A lot of researches are still being conducted to improve its properties and lower its manufacturing cost in order to implement its use in real life applications. In the coming years, this material will innovate the world of technology due to its unique characteristics.

REFERENCES

1.Zaheen Ullah Khan, Ayesha Kausar & Hidayat Ullah (2016) A Review on Composite Papers of Graphene Oxide, Carbon Nanotube, Polymer/GO, and Polymer/ CNT: Processing Strategies, Properties, and Relevance, Polymer-Plastics Technology and Engineering.

2.Nasir, A.; Kausar, A.; Younus, A. Polymer/graphite nanocomposites: Physical features, fabrication and current relevance. Polym. Plast. Technol. Eng. 2015 Nasir, A.; Kausar, A.; Younus, A. Polymer/graphite nanocomposites: Physical features, fabrication and current relevance. Polym. Plast. Technol. Eng. 2015.

3.Putz, K.W.; Compton, O.C.; Palmeri, M.J.; Nguyen, S.T.; Brinson, C. High-nanofiller-content graphene oxide-polymer nanocomposites via vacuum-assisted self-assembly. Adv. Funct. Mater. 2010.

4.Thostenson, E.T.; Ren, Z.; Chou, T.-W. Advances in the science and technology of carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2001.

5.Shimotani, K.; Anazawa, K.; Watanabe, H.; Shimizu, M. New synthesis of multi-walled carbon nanotubes using an arc discharge technique under organic molecular atmospheres. Appl. Phys. A: Solids Surf. 2001.

6.Kumar, M.; Ando, Y. Chemical vapor deposition of carbon nanotubes: a review on growth mechanism and mass production. J. Nanosci. Nanotechnol. 2010.

7.Zhu, W.; Zeng, C.; Zheng, J.P.; Liang, R.; Zhang, C.; Wang, B. Preparation of buckypaper supported Pt catalyst for PEMFC using a supercritical fluid method. Electrochem. Sol. Stat. Lett. 2011.

8.Zhang, J.; Jiang, D.; Peng, H.-X.; Qin, F. Enhanced mechanical and electrical properties of carbon nanotube buckypaper by in situ cross-linking. Carbon 2013.

9.Whitby, R.L.D.; Fukuda, T.; Maekawa, T.; James, S.L.; Mikhalovsky, S.V. Geometric control and tuneable pore size distribution of buckypaper and buckydiscs. Carbon 2008.

10.Kukovecz, A.; Smajda, R.; Konya, Z.; Kiricsi, I. Controlling the pore diameter distribution of multiwall carbon nanotube buckypapers. Carbon 2007.

11.Duggal, R.; Hussain, F.; Pasquali, M. Self-assembly of single-walled carbon nanotubes into a sheet by drop drying. Adv. Mater. 2006.

12.Structural Properties of Chemically Functionalized Carbon Nanotube Thin Films, G. Trakasis, D. Tasis, C. Galiotis, Institute of Chemical Engineering and High Temperature Processes, Foundation of Research and Technology Hellas, 10 June 2013.

REFERENCES FOR IMAGES

1.Structural Properties of Chemically Functionalized Carbon Nanotube Thin Films, G. Trakasis, D. Tasis, C. Galiotis, Institute of Chemical Engineering and High Temperature Processes, Foundation of Research and Technology Hellas, 10 June 2013.

2.Zaheen Ullah Khan, Ayesha Kausar & Hidayat Ullah (2016) A Review on Composite Papers of Graphene Oxide, Carbon Nanotube, Polymer/GO, and Polymer/ CNT: Processing Strategies, Properties, and Relevance, Polymer-Plastics Technology and Engineering.

3.Zaheen Ullah Khan, Ayesha Kausar & Hidayat Ullah (2016) A Review on Composite Papers of Graphene Oxide, Carbon Nanotube, Polymer/GO, and Polymer/ CNT: Processing Strategies, Properties, and Relevance, Polymer-Plastics Technology and Engineering.

4.Zaheen Ullah Khan, Ayesha Kausar & Hidayat Ullah (2016) A Review on Composite Papers of Graphene Oxide, Carbon Nanotube, Polymer/GO, and Polymer/ CNT: Processing Strategies, Properties, and Relevance, Polymer-Plastics Technology and Engineering.

Recent Posts

-

MXenes from MAX Phases

MXenes, a group of two-dimensional materials derived from MAX phases, are gaining significant tracti …19th Oct 2024 -

Preserving History with Graphene's Power

Cultural artifacts are at risk of deterioration over time due to the destructive effects of both na …11th Oct 2024 -

The Role of Graphene in Neuroelectronics

Neuroelectronics is an interdisciplinary field that aims to develop devices that can interact with t …4th Oct 2024