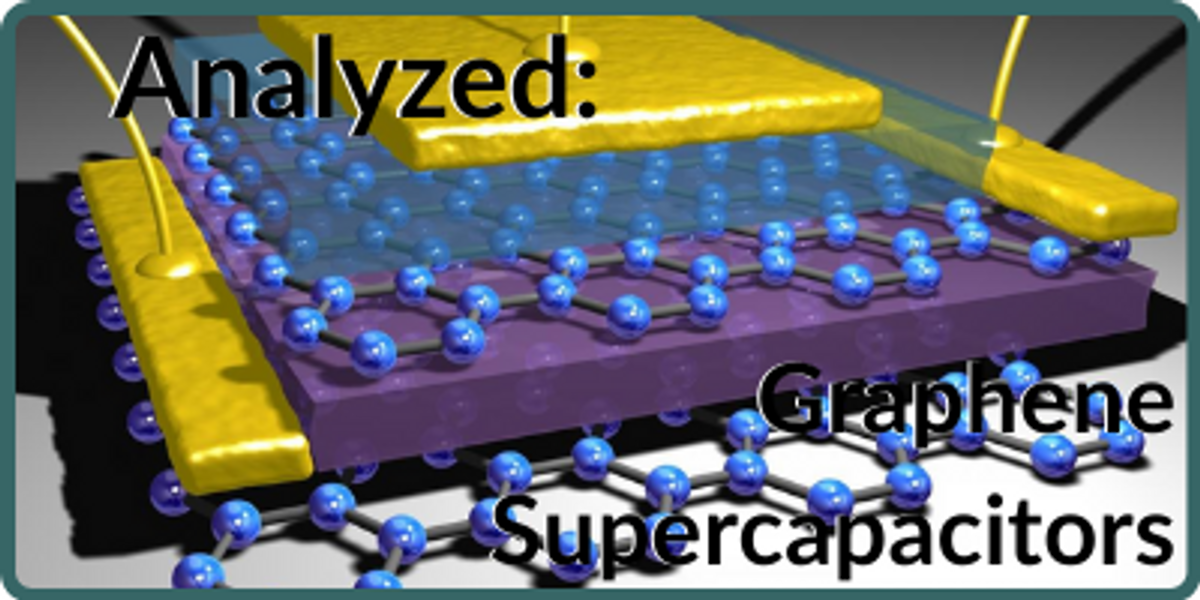

Analyzed: Graphene Supercapacitors

Supercapacitors are formed by pairs of conductive plates separated by a dielectric medium. Its operation is very similar to that of a large-scale capacitor. However, the name of the supercapacitor indicates its greater capacity, thousands of times greater than the capacity of high capacity electrolytic capacitors, being able to charge and discharge in very short periods. Graphene has a lot of potential in the construction of Supercapacitors, therefore this article aims to discuss the role of Graphene Supercapacitors in detail.

Background

In the 80’s the first 1 Farad supercapacitor was developed. However, it was not until the 1990s that the interest in it as an applicable energy storage system, especially in the automotive sector, aroused. Currently, commercial supercapacitors are carbon-based with an alkali metal or alkaline earth metal electrolyte.

Let’s first get to know about Capacitor, Supercapacitor, and batteries.

Capacitor

Beyond the batteries today we already have other devices capable of storing electrical energy, the capacitors. They are used in many electronic mechanisms that we use daily. The advantages of a capacitor are that it can be loaded and unloaded very quickly, and has a reduced cost, but the disadvantage is that it does not accumulate much energy. Supercapacitors are capable of storing much more energy (and already exist since 1957).

Supercapacitor

In addition to the lines of research in new batteries, there are also several lines of research in new supercapacitors, the most promising being graphene as an alternative for the future for electronic devices and of course for electric vehicles.

The area of the plates is the factor that most influences their capacity. To increase it you can increase its roughness and even provide porosity. Therefore, the future of supercapacitors is graphene nanotubes, which have a porosity greater than that of the carbon commonly used.

This porosity also makes the loading and unloading speed of the supercapacitor greater. Although the useful life decreases with capacity, this is not a problem, since it has been seen that the half-life is greater than 20 years, with no appreciable losses in tension.

Batteries and supercapacitors complement each other. While the former provides energy, supercapacitors provide power peaks.

What is Graphene?

Find out more about Graphene in this comprehensive post: The Ultimate Guide to Graphene

Graphene is a form of carbon, and it is also an organic compound that can not only be recycled without contaminating but is compostable and would be used to make fertilizer along with other organic remains. With graphene, we could manufacture capacitors that would have much more capacity than the current ones and that would not be as polluting at the time of being discarded, or they would not be as delicate to recycle as current batteries.

And we would also maintain the advantages of the capacitors, so we would have an electric car at a lower price than if it had batteries, it could have more autonomy and above all, it could be recharged much faster, in one or two minutes.

Can we wait while driving to fully recharge a car in just a few minutes?

Probably not since this would require excessively high load powers, but we could have partial recharges at high power, but acceptable, with which to recover part of the autonomy of the car in less time than now.

Other options could be to find wireless charging systems even more useful and recharge taking advantage of short stops such as traffic lights or have charging stations that accumulate energy throughout the day, and transfer it very quickly to the supercapacitors of the car.

Another added advantage is that the fast recharging of a supercapacitor does not present problems on the life of the accumulator, a problem that is not eliminated when using the fast recharge in batteries (it is advisable not to abuse the rapid recharge in the ion batteries of lithium and the cooling system of the same must be very well studied so that the high power recharge does not overheat and deteriorate them).

Advantages of Graphene in Batteries

Graphene can also be used with advantage in the electrochemical batteries themselves, to make electrodes with a high reaction surface, as we have discussed on several occasions, regarding its use in Lithium, or Lithium-Air cells, just to give some recent examples.

In this sense, it can be said that graphene has triggered a sort of virtuous competition between the electrochemical and physical pathways for the creation of ever more capacious energy accumulators.

In capacitors, the charge accumulation capacity strongly depends on the surface and spatial characteristics of the structure (geometric aspects such as small distances and sharp points are of great help) and graphene excels above all regarding the surface/volume ratio and the surface/mass ratio: the latter can reach and exceed the incredible value of 2600 square meters per gram of substance.

Further help may come from the use of advanced construction techniques to combine this intrinsic property with three-dimensional microstructures, further increasing the almost "fractal" properties (in terms of surface/volume ratio) typical of graphene. With the concrete prospect of overcoming electrochemical batteries in terms of energy density, but above all of eclipsing them in terms of charging speed.

Want to learn more about Graphene Batteries?

Check Lithium Ion Batteries vs. Graphene Batteries also.

More Capacious Batteries with Graphene Supercapacitors

Quantitative information is not currently available, but the researcher claims that the graphene supercapacitor has an energy density equal to that of a lithium battery. It is a predictable and expected step, after that, for example, in 2010 it had been announced an ultracapacitor, always at graphene, capable of storing more than 85 Wh/kg at ambient temperature and more than 130 Wh/kg at 80 °C.

For reference, the energy density of a NiMH battery is around 80 Wh/kg, while that of a conventional Li-Ion rechargeable battery can range between about 100 and about 200 Wh/kg. It is therefore not surprising that after many years of research someone could have realistically come to realize graphene nanostructures capable of exhibiting an even higher and now equal, if not better, electric charge storage capacity than many lithium batteries.

The advantages are many: rare or precious substances are not required, nor is the environment wasted to extract the necessary materials (the main component, graphene, is nothing more than an allotropic form of the very common carbon); the manufacturing costs, duty of industrial processes, should be low; a long service life is expected for the component; the charging transactions may take place in a very short time; the structure of the constituent elements (similar to thin sheets of paper) will allow unthinkable applications, including even integration into clothes.

Graphene Supercapacitors: Future of the Energy Accumulation Industry

Supercapacitors are a type of component that stores electricity in an electric field (that is, without using chemical processes such as batteries). When there is no chemical reaction, they do not degrade. Also, they can initially be charged faster than a battery in use.

However, there are two main reasons why supercapacitors have not been able to replace the batteries that we find for example in electric cars: they can store less energy in the same amount of space, and they cannot retain it for so long: a supercapacitor completely charged can be emptied in just a few hours, instead of in weeks as batteries.

Currently, there are a lot of researchers and companies trying to develop better supercapacitors that do not suffer from these inconveniences. One of the key materials to achieve this is the famous graphene, which as you already know is formed by thin layers of carbon atoms arranged in hexagonal structures. On paper, it is strong and light, with a large surface area, and is a great conductor of heat and electricity. However, the industrialization of graphene progresses very slowly.

Due to its large surface area (which determines the performance of a supercapacitor), graphene has great potential to definitively improve the performance of supercapacitors, allowing its use in applications such as electric cars and electronic consumer devices. Thus, smartphones could be built with the ability to charge in just a few seconds, or even electric vehicles with charging times similar to the refueling time of a thermal car.

The graphene battery market is expected to reach a value of 115 million dollars by 2022, although it has potential beyond that because of the continuous technological improvements and the interest of numerous companies in it. However, there is still a lot of research to be done before graphene supercapacitors can maintain their charge long enough to be an alternative to current batteries.

Some experts have suggested the creation of hybrid systems that use supercapacitors for fast charging and batteries for long-term storage, a system that addresses one of the main problems of this root technology.

A new production method for graphene supercapacitors has been developed in Australia that is based on traditional papermaking.

An Innovative Way of Producing Graphene Supercapacitors

Following an experiment to create batteries with greater energy power, a team of engineers from the University of Monash, in Australia, has come up with a method of producing graphene similar to that traditionally used to make paper. The achievement has arisen in the face of the need to create supercapacitors with this material, which can finally house an energy density up to 10 times higher than that of today's commercial devices, which would be the equivalent of a car battery.

To build these devices, scientists at Monash University, located in the Australian city of Melbourne, needed to use graphene and, as is usually the case with this material, the mass production process is difficult and expensive. This leads to many of the investigations that explore the uses of this carbon derivative to start investigating new ways of manufacturing it since otherwise practical applications are worthless since the material cannot be obtained comfortably.

In this case, the team of engineers employed the traditional papermaking process, modifying it slightly, to produce the desired material. They took graphite oxide and mixed it with a solution of hydrazine and ammonia to give rise to a compound with low-grade graphene flakes. Then a substance was added that acts as an electrolyte (one of the basic components of a battery). When volatile liquids evaporate the different graphene particles come together and the result is what a black sheet of paper looks like, actually millions of layers of the material that also contain the electrolyte.

Graphene Supercapacitors

In this way, the material could be manufactured on a large scale to use it in the supercapacitors that Australian engineers have designed. This type of device consists of a battery that can be charged and discharged almost instantaneously, just as with a car. Its energy density is low, which means that it is useful when a large power is required in a short space of time, but it does not serve as a continuous power source, such as a smartphone needs.

The novelty in this research, how could it be otherwise, comes from graphene. In a battery, the larger the surface of the electrodes, the more ions can be absorbed, which is equivalent to storing more energy. Carbon-derived material, which takes the form of two-dimensional sheets of an atom of thickness, can offer a considerably wider extent than is known until now.

With this feature, a supercapacitor retains enough energy to act as a continuous power supply, but without losing the ability to display a large power for a moment.

Analysis Verdict

Thus, Graphene Supercapacitors offer a variety of advantages and it can store more and more energy for a longer period. It’s an updated form of batteries and it is only a matter of time before graphene supercapacitors come in the market and are used extensively by electronic devices. Graphene Supercapacitor is the future of the Electronics Industry.

Read more about Graphene in our Explained: Graphene article.

References

https://www.nature.com/subjects/supercapacitors/ncomms

https://www.sciencedirect.com/topics/materials-science/graphene

https://iopscience.iop.org/article/10.1088/1361-6528/aa8948/meta

https://pubs.rsc.org/en/content/articlelanding/2013/ta/c3ta12193c#!divAbstract

https://www.greencarcongress.com/2013/08/monash-20130803.html

Recent Posts

-

Advanced Materials for Unmanned Aerial Vehicle (UAV) Protection Against Laser

Consider a UAV on a critical mission, rendered inoperative by a sudden laser attack. With the increa …26th Jul 2024 -

Simulation and Modeling of Material Properties

Our world is composed of a dazzling array of materials, each with its own unique properties that dic …19th Jul 2024 -

Advanced Coatings for Superior Corrosion and Wear Resistance

Corrosion and wear pose significant challenges across various industries, leading to substantial eco …12th Jul 2024