Description

25 grams/85 €

100 grams/180 €

500 grams/580 €

1000 grams/995 €

5000 grams/4425 €

Please contact us for quotes for larger quantities !

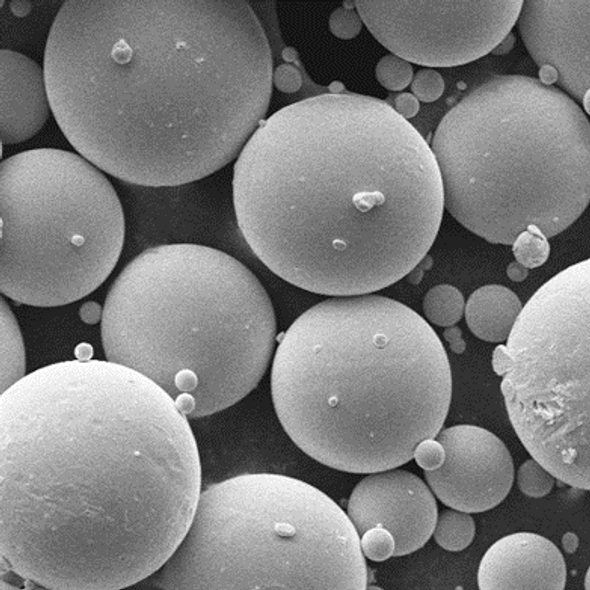

Titanium Alloy Micron Powders, CPTi, 15-35 µm, Spherical

Metal alloys are highly used in 3d printing with the advancing technologies. Three-dimensional printing (3D) and the technique of additive manufacturing (called AM) of metallic materials are testifying important advances. With the improvement of both research-grade and commercial production of 3D printing equipments, along with an increased diversity of feedstock materials, has promoted important research activities in academic, government, and industrial research institutions, worldwide. The most outstanding usages of 3D metal printing involve powder beds, streams of gas-propelled powder jets or wire for feedstock, lasers and electron beams as the energy sources, and precision automation equipment for digitally directing the energy source, the feedstock, or both along the material/energy deposition pathways.

The composition of titanium alloy TC4 material is Ti-6Al-4V. They belong to (α+β) type titanium alloy and has good comprehensive mechanical and mechanical properties. TC4 titanium alloy has excellent corrosion resistance. Also, they have many advantages like low density, high specific strength, and good toughness and weldability. Their applicatiıon areas include aerospace, petrochemical, shipbuilding, automotive, pharmaceutical and other sectors.

The powder can be used in a wide range of metal 3D printers including Renishaw, EOS, ConceptLaser, SLM, 3Dsystems, Arcam and more.

Metal alloys are highly used in 3d printing with the advancing technologies. Three-dimensional printing (3D) and the technique of additive manufacturing (called AM) of metallic materials are testifying important advances. With the improvement of both research-grade and commercial production of 3D printing equipments, along with an increased diversity of feedstock materials, has promoted important research activities in academic, government, and industrial research institutions, worldwide.

Application areas:

- 3D Printing: Titanium is the strongest and the lightest material for 3d printing at the same time. It is used in the process called Direct Metal Laser Sintering (DMLS)

- High tech fields: Space exploration, aeronautics, and medical field

- Petrochemical

- Shipbuilding

- Automotive

- Pharmaceutical

- Manufacturing prostheses

- Direct metal deposition

- Binder jetting 3d printer technologies

- Powder bed fusion

The most outstanding usages of 3D metal printing involve powder beds, streams of gas-propelled powder jets or wire for feedstock, lasers and electron beams as the energy sources, and precision automation equipment for digitally directing the energy source, the feedstock, or both along the material/energy deposition pathways.

The composition of titanium alloy TC4 material is Ti-6Al-4V, and has good comprehensive mechanical and mechanical properties.

Distinct Characteristics of Ti-6Al-4V:

- Low density

- High specific strengths

- Good toughness

- Weldability

- Biocompatible

- Resists corrosion