Uses of Boron Nitride (BN) Nanopowder/Nanoparticles

Boron nitride (BN) nanopowder, with its exceptional thermal conductivity, electrical insulation, and chemical stability, stands as a versatile material with applications ranging from electronics to medical technology.

Thanks to its unique hexagonal structure and biocompatibility, BN nanopowder is an advanced material that meets diverse industrial needs. In this article, the structure, properties and application areas of Boron Nitride nanoparticles will be examined in detail. Check out our wide range of elemental, oxide and compound nanoparticles now.

Introduction

Boron nitride (BN) nanopowder, also known as "white graphene" due to its structural similarity to graphene, has gained increasing attention in recent years. This advanced material combines high thermal conductivity with excellent electrical insulation, making it ideal for various applications in electronics, thermal management, and medical fields. Moreover, BN's resistance to oxidation and its chemical stability under extreme conditions make it an essential component in challenging environments. In this blog, we’ll explore the diverse uses of boron nitride nanopowder and its potential to transform various sectors with its cutting-edge properties.

Boron Nitride Nanostructures

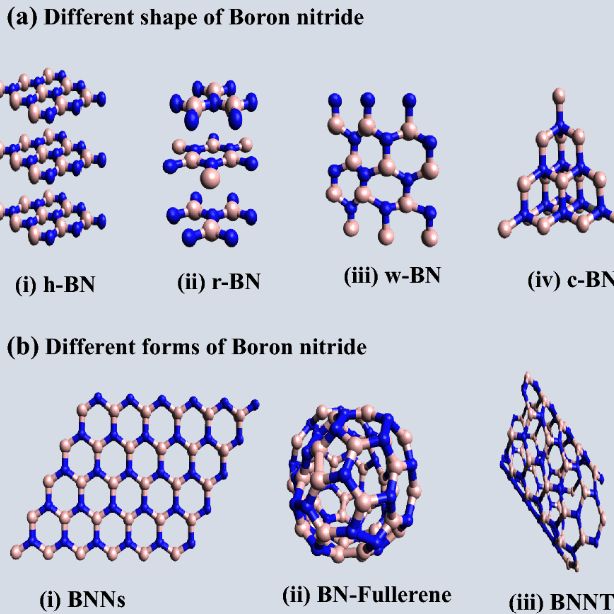

Boron Nitride (BN) nanostructures are composed of alternating Boron and Nitrate atoms. This arrangement does not commonly occur in nature hence they are produced synthetically. BN nanostructures are often compared to well-known carbon nanostructures. This is because BN is isoelectronic to a carbon lattice and has several crystalline forms. Cubic BN forms that resemble diamond structure, wurtzite BN forms similar to lonsdaleite, rhombohedral BN forms with ABC stacking similar to r-graphite, and hexagonal BN forms with AB stacking that resemble h-graphite are the well known BN structures. Amongst these forms hexagonal BN (h-BN) form is the most stable one. Therefore, most of the researches focuses on h-BN structures. Even though the amount of research on BN nanostructures is far less than the research on carbon nanostructures, they have been attracting more and more attention lately.

BN nanomaterials can be categorized by their dimensions; zero-dimensional (0D) fullerenes and nanoparticles, 1D nanotubes and nanoribbons, 2D nanosheets, and 3D nanoporous BN structures.

BN Fullerenes is composed of nested rings while BN nanoparticles have a spherical shape. The shape of BN nanotubes was inspired by carbon nanotubes (CNTs). They can be imagined as rolls of hexagonal BN layers with diameters of 10-100 nm. BN nanosheets are in nanoscale only in one dimension (thickness) and infinite in the other two. Mono layered h-BN nanosheets are also called “white graphenes” due to their resemblance to the graphene structure of carbon. Nanoporous BN structures are 3D materials with high-porosity. BN nanostructures are generally produced in powder form.

Even though BN nanostructures are compared to carbon nanostructures they, in fact, have very different properties. In contrast to the pure covalent bond between C atoms, the bond between B and N atoms is partially ionic [1]. Because of this difference in the bond characteristic, BN nanostructures present different optical, electrical, and chemical properties than carbon nanostructures.

Figure 1. Nanostructured boron nitride–based materials.

Properties of Boron Nitride Nanostructures

Structurally, BN fullerenes are generally composed of nanosized cages with 4,6 and 8 rings. The size of these cages is around 2 nm. Diameters of spherical BN nanoparticles vary between 10-400 nm. The thickness of monolayered BN nanosheets is in atomic sizes while the diameter of BN nanotubes varies between 10 and 100 nm.

The properties of BN nanostructures build on the properties of h-BN. Boron Nitride nanostructures show insulating properties with a wide bandgap of 5-6 eV. Insulating properties of BN nanotubes and nanosheets doesn’t depend on the details of the atomic structure. This behavior provides a stable bandgap that doesn’t depend on curvature or helicity. However, BN nanoribbons have a lower emission voltage, around 1-1.3 V/μm, suggesting a metallic behavior.

Investigations on thermal properties of BN nanoparticles show that they show excellent thermal conductance and high specific heat. The thermal conductance of BN nanosheets is especially remarkable with values over 600 W/mK. The thermal conductivity of BNNTs is lower than nanosheets with values around 350 W/mK. Also, the thermal conductivity of BNNTs is independent of its diameter and chirality. The thermal stability of BNNTs is also a promising feature. The oxidation resistance of BNNTs is around 830°C. This property attracts attention because it is much higher than the carbon nanostructures.

BN nanostructures also present great mechanical properties. Young’s Modulus of h-BN varies between 0.81-1.3 TPa. Accordingly, the elastic modulus of BNNTs can go up to 1.3 TPa and their tensile strength is around 33 GPa.

In contrast to black carbon nanostructures, the color of BN nanostructures is white and even almost transparent. Optically, BN nanoparticles exhibit excellent ultraviolet (UV) emissions.

While h-BN films are partially wettable with a 50° contact angle, BN nanotubes are highly hydrophobic with contact angles up to 150°. So, the wetting properties of BN nanostructures vary between hydrophilicity to superhydrophobicity. Furthermore, because of the chemical stability of the h-BN structure, the hydrophobicity or hydrophilicity of BN nanostructures is not affected by the pH value of water. Chemical stability of the BN nanostructures stems from

What are the Application Areas of Boron Nitride Nanoparticles?

There are many possible application areas of BN nanostructures due to their desired properties at the nanoscale. High thermal conductivity, mechanical strength, chemical inertnss, and insulating properties have the potential to be exploited by several industries.

Applications of BN Nanoparticles

The high thermal conductivity of BN nanoparticles is utilized in nanofluids. Adding BN nanoparticles to conventional heat transfer fluids improves the thermal conductivity and consequently enhances the thermal transport. Nanofluids can be used in heat exchangers for rapid cooling or heating applications.

Superior mechanical strength of BN nanoparticles is used to construct ultra-hard cubic Boron Nitride (c-BN) with Vickers Hardness larger than 100 GPa. This value exceeds the optimal hardness of synthetic diamonds. In addition to unique mechanical toughness, c-BN also shows considerable fracture toughness and high oxidation resistance. Due to these unique properties, c-BN can be utilized as a high-performance abrasive material in place of diamond. Furthermore, c-BN is effective at precise sculpting of ferrous based materials.

Applications of BN Nanotubes

Much like carbon nanotubes, BN nanotubes are utilized as a reinforcement agent in composites. BN nanotubes are used as composite fillers mostly in polymer, ceramic and metal composites. Due to their high mechanical strength and thermal conductivity, BN nanotubes improve the strength of these composites while also improving the thermal conductivity of the material. The thermal conductivity of different polymers can be increased by 4.5 to 14.7 times with different loading ratios.

Another application of BN nanotubes is hydrogen uptake and storage. Due to their high surface area and polarity BN nanotubes have the potential to be used as hydrogen storing materials in the hydrogen energy industry. Other promising application areas of BN nanotubes are; insulating coatings, ultraviolet luminescence, and field emission. Due to the wide bandgap of h-BN structure, BN nanotubes present high electrical insulating properties.

Applications of BN Nanosheets

Much like BN nanotubes, BN nanosheets are used as a reinforcing agent in polymers. Along with mechanical strength, BN nanosheets offer better thermal conductivity than BN nanotubes and provide chemical stability against degradation. Owing to these properties, BN nanosheets are excellent additives for polymers and other composites. BN based composites also have the potential to be used in the packaging industry because of their high thermal conductivity which provides quick heat release.

Alternatively, BN nanosheets are used in microelectronic applications. Combining semiconducting properties of carbon nanostructures with insulating properties of BN nanosheets enables the construction of electrical circuits, field-effect transistors, and tunneling devices. Moreover, the smooth surface of BN nanosheets can improve the device quality and performance while chemical inertness of BN nanosheets offers protection against corrosion.

Carbon-doped BN nanosheets show excellent photocatalytic properties and have the potential to be used as a photocatalyst in H2 production and oxidation of water pollutions.

Other possible application areas of BN nanosheets can be listed as; lubricants, superhydrophobic materials, and oxidation-resistant coatings.

Applications of Nanoporous BN

Nanoporous BN combines the excellent BN properties with the high surface area of the porous structure. High chemical stability and thermal conductivity of the porous BN allow its use in hydrogen storage, catalyst support, pollution treatment, and drug delivery systems.

Adsorption properties of porous BN structures are used for water pollution treatments. Inorganic particles such as heavy metals and sulfate, phosphate, nitrate, and chloride anions; organic particles such as dyes cause water pollution. The high concentrations of these pollutions threaten human and animal health and the environment. Thus, water treatment is a necessity in our world. The high surface area and chemical inertness of porous BN are suitable for pollutant removal. Porous BN can uptake 3300 wt% of the adsorbates exhibiting a great removal potential. Furthermore, they have great cycling performances allowing the material to be used for a long period of time.

Much like BN nanotubes, porous BN nanostructures can be used for hydrogen storage applications. Under 1 MPa and at 77K, nanoporous BN was found to uptake 2.6 wt% hydrogen.

Conclusion

Boron Nitrate is a widely utilized substance in the industry. With the developments in nanotechnology, nanostructures of BN have also attracted attention. Unique properties of hexagonal-BN arrangement are heavily exploited in nanoscale. h-BN based nanostructures show high thermal conductivity, high electrical resistance, chemical inertness, ultraviolet luminescence, and mechanical strength. Different applications are possible through exploiting these properties. BN nanostructures are used for thermal conductivity enhancement, mechanical strength enhancement, insulating coatings, oxidation and corrosion-resistant coatings, electrical circuits, water treatment, and hydrogen storage.

Several BN nanostructures such as BN nanotubes and nanoparticles are used to improve the thermal conductivity of composites and nanofluids. Mechanical strength of polymer, ceramic and metal composites are improved by using BN nanotubes as composite fillers. BN nanotubes and nanoporous BN structures have the potential to be used in hydrogen storage applications due to their high specific surface area. BN nanoparticles are used for obtaining super-hard c-BN materials to precise cutting applications. Even though industrial applications of BN nanostructures are still in infancy, there is great potential for rapid growth.

For more insights on nanomaterials and the latest developments, along with informative contents, visit Blografi.

References

Analyzed: Carbon Nanotubes - Nanografi Nano Technology. (n.d.). Retrieved October 31, 2024, from https://nanografi.com/blog/analyzed-carbon-nanotubes/

Boron Nitride Nanoparticles - Nanografi Nano Technology. (n.d.). Retrieved October 31, 2024, from https://nanografi.com/blog/boron-nitride-nanoparticles/

Golberg, D., et al., Boron nitride nanotubes. Advanced Materials, 2007. 19(18): p. 2413-2432.

Improvement of Hydrogen Storage with Nanomaterials - Nanografi Nano Technology. (n.d.). Retrieved October 31, 2024, from https://nanografi.com/blog/improvement-of-hydrogen-storage-with-nanomaterials-9752b8/

Jiang, X.-F., et al., Recent progress on fabrications and applications of boron nitride nanomaterials: a review. Journal of Materials Science & Technology, 2015. 31(6): p. 589-598.

Nanocomposites in Food Packaging - Nanografi Nano Technology. (n.d.). Retrieved October 31, 2024, from https://nanografi.com/blog/nanocomposites-in-food-packaging/

Nanosensors in Detecting and Monitoring Water Pollutants - Nanografi Nano Technology. (n.d.). Retrieved October 31, 2024, from https://nanografi.com/blog/nanosensors-in-detecting-and-monitoring-water-pollutants/

Pakdel, A., et al., Low-dimensional boron nitride nanomaterials. Materials Today, 2012. 15(6): p. 256-265.

Revabhai, P. M., Singhal, R. K., Basu, H., & Kailasa, S. K. (2023). Progress on boron nitride nanostructure materials: properties, synthesis and applications in hydrogen storage and analytical chemistry. Journal of Nanostructure in Chemistry, 13(1), 1–41. https://doi.org/10.1007/S40097-022-00490-5

Vickers hardness test - Wikipedia. (n.d.). Retrieved October 31, 2024, from https://en.wikipedia.org/wiki/Vickers_hardness_test

Yu, S., et al., Boron nitride-based materials for the removal of pollutants from aqueous solutions: a review. Chemical Engineering Journal, 2018. 333: p. 343-360.

Weng, Q., et al., Functionalized hexagonal boron nitride nanomaterials: emerging properties and applications. Chemical Society Reviews, 2016. 45(14): p. 3989-4012.

Wort, C.J.H., Applications for Superhard and Ultra-Hard Materials, in Microstructure-Property Correlations for Hard, Superhard, and Ultrahard Materials. 2016, Springer. p. 25-74.

Recent Posts

-

A New Approach to Obesity with Nanotechnology

Obesity stands out as a complex global health crisis that significantly increases the risk of chroni …1st Nov 2024 -

Graphene is the Word in Bionic Technology: EGNITE

Neuroprosthetic technologies have made significant advancements in recent years to enhance the qual …25th Oct 2024 -

MXenes from MAX Phases

MXenes, a group of two-dimensional materials derived from MAX phases, are gaining significant tracti …19th Oct 2024