Use of Carbon Nanotube in Touch Screen Technologies

Carbon nanotube (CNT)-based transparent electrodes offer flexibility, durability and cost advantages in touchscreen technology, providing a strong alternative to other electrode materials such as traditional indium tin oxide (ITO).

CNT films address a wide range of applications from mobile devices to flexible displays. Especially multi-touch and force sensing properties are among the innovative solutions offered by CNT technology for touch screens. In this article, the advantages of CNT-based transparent electrodes as an alternative to ITO will be discussed and how CNTs offer an innovation in touch screen technology will be analysed under separate headings. Meet Nanografi, Türkiye's first nanotechnology company where carbon nanotubes and all other carbon-based materials are produced in Türkiye's largest production facility.

Introduction

Touch screen technology has become one of the most basic tools of interaction in modern devices. This technology, which has a wide range of usage areas from smartphones to tablets, from laptops to automobile screens, has gained an indispensable place in the daily lives of users. However, one of the most important factors determining the functionality, durability and performance of touch screens is the electrode material used. Materials such as indium tin oxide (ITO), which have been used as a standard solution for traditional touch screens for many years, offer advantages in terms of transparency and conductivity, but their disadvantages such as limited flexibility, cost and rare availability have brought the search for new generation materials to the agenda.

At this point, nanomaterials offer great potential. In particular, carbon nanotubes (CNT) stand out as a remarkable alternative in terms of flexibility, durability and cost for electrodes used in touch screens.

What is Carbon Nanotube Based Transparent Electrode?

Carbon nanotube (CNT) based transparent electrodes are thin, permeable and highly electrically conductive surfaces used in electronic devices such as touch screens. These electrodes consist of nanotubes in which carbon atoms are arranged in a tubular shape and have many advantages over conventional electrode materials. They are called ‘transparent’ because they transmit most of the visible light, reducing the visibility of the electronic components under the display. Thus, users can maintain the clarity and brightness of the display without compromising the visual quality of the device.

Carbon nanotubes have the ability to transmit light because they have an atomically thin and tubular structure. This property makes CNT-based electrodes an ideal choice in applications where transparent and durable surfaces are needed, such as touch screens. Unlike the traditionally used indium tin oxide (ITO) material, CNT-based electrodes are both more flexible and resistant to breakage, making them attractive for next-generation technologies such as flexible displays or bendable devices.

Application Process of Carbon Nanotube Based Transparent Electrodes

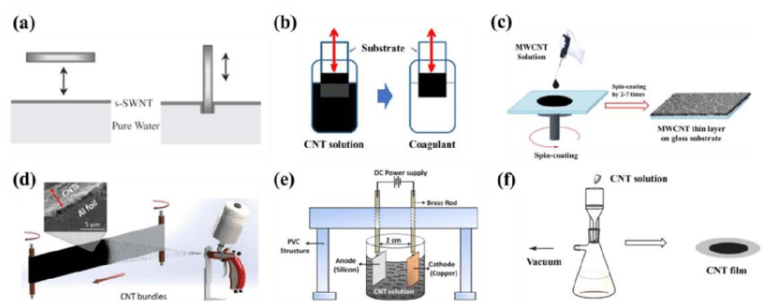

The use of carbon nanotube (CNT) based transparent electrodes in touch screens requires a specific manufacturing process. CNTs are usually in the form of ink, which is coated on the touchscreen surface to form a thin film. Here are the basic steps in the application process of CNT-based transparent electrodes:

1. Ink Preparation and Coating: Carbon nanotubes are mixed with special inks prepared with water-based or organic solvents to ensure a homogenous distribution. This ink is applied to the touch screen surface by methods such as roller coating, spray coating or printing. The coating process is important for the CNTs to spread evenly on the surface.

2. Drying Process: After the ink is applied to the surface, the solvent is evaporated and dried so that the CNT network remains on the surface. During this process, the coated CNTs are stabilised and become electrically conductive.

3. Patterning: After the drying process is completed, patterning is performed to create specific touch areas on the touch screen. With techniques such as laser ablation or plasma etching, CNTs in certain areas are removed from the surface to create independent touch sensing areas.

4. Connection and Integration: In the final step, the patterned CNT layer is combined with other components of the touchscreen and integrated into the display's operating circuits. In this step, CNT-based electrodes are connected for touch sensing and signal transmission, which are the main functions of the touch screen.

Once these steps are complete, CNT-based transparent electrodes are ready to be used as a flexible, durable and high-performance solution in touch screens. This application process enables large-scale production of CNT-based electrodes, providing an efficient alternative in touchscreen technology.

Figure 1. Schematic representation of one of the CNT film production methods.

Advantages of Carbon Nanotube Based Touch Screens

CNT films stand out as a prominent material for applications that require durability and flexibility in touch screens. CNT-based transparent electrodes offer a long service life with a structure resistant to millions of touches. According to research, CNT films have a durable structure that can withstand 3 million touch tests. This feature makes CNT preferred in mobile devices and industrial display applications and provides long-term use by increasing device life.

In addition, the ability of CNT films to provide a clear image even in sunlight thanks to its low reflection rate greatly improves the user experience. CNT-based films with a reflection rate below 9% preserve natural colours and improve screen readability without the need for extra anti-reflective coatings. This feature facilitates screen use, especially in open areas or under bright light.

- Flexibility and Bendability: One of the most important advantages of CNT-based electrodes is their flexibility. With the increasing popularity of bendable displays, CNT films have become an ideal material for curved displays and foldable devices. While brittle structures such as traditional ITO perform poorly in displays that require flexibility, CNT films are more resistant to bending and flexing. This flexibility offers new possibilities in device designs, while ensuring the long life of displays and minimising the risk of breakage.

- Multi-Touch and Force Sensing Capability: SWCNT (single-walled carbon nanotube) based touch screens provide an enhanced user experience with features such as multi-touch and force sensing. This technology enriches the user interaction of the screen by detecting the touch force as well as the touch point. For example, users can trigger different commands according to the pressure they apply to the screen, which is a major innovation, especially in interactive displays and user-friendly devices. CNT-based touch screens can work not only with conductive surfaces, but also with insulating surfaces. While conventional capacitive touch screens are only sensitive to conductive touch such as the human finger, CNT films can also interact with insulating materials. This feature makes the use of the display more flexible and functional in laboratory and industrial applications.

- Production Process and Cost Advantages: Carbon nanotube films also provide significant advantages in terms of production process and cost. Roll coating methods used in the production of CNT films can be applied quickly and efficiently on large surfaces. This method is less costly compared to vacuum-based coating processes and allows large-scale production. In researches, it has been reported that CNT films are produced by aqueous-based coating technique, which is more economical and faster than vacuum-based ITO production processes. In the production process, CNTs are grown, special ink formulations and thin film coating processes are applied. This method offers the possibility to easily adapt the resistance and transparency properties of CNT films according to device needs and provides cost efficiency.

For more information about carbon nanotube-based transistors, visit our blog.

Conclusion

Carbon nanotube (CNT)-based transparent electrodes offer a more flexible, durable and cost-effective solution in touchscreen technology compared to traditional materials such as indium tin oxide (ITO). This technology appears to have great potential in next-generation devices such as flexible displays, foldable devices and applications requiring multi-touch and force sensing capabilities.

Cost efficiency in the manufacturing process and the possibility of application on large surfaces also make CNTs ideal for large-scale use. These innovative advantages of CNT-based electrodes have the potential to create a significant change in the industry by enabling touch screen technology to move towards more user-friendly, durable and flexible devices in the future.

To follow the latest developments and innovations related to nanotechnology and advanced materials, visit Blografi.

References

Analyzed: Carbon Nanotubes - Nanografi Nano Technology. (n.d.). Retrieved November 4, 2024, from https://nanografi.com/blog/analyzed-carbon-nanotubes/

Hecht, D. S., Thomas, D., Hu, L., Ladous, C., Lam, T., Park, Y., Irvin, G., & Drzaic, P. (2009). Carbon-nanotube film on plastic as transparent electrode for resistive touch screens. Journal of the Society for Information Display, 17(11), 941–946. https://doi.org/10.1889/JSID17.11.941

Kim, W., Oh, H., Kwak, Y., Park, K., Ju, B. K., & Kim, K. (2015). Development of a Carbon Nanotube-Based Touchscreen Capable of Multi-Touch and Multi-Force Sensing. Sensors 2015, Vol. 15, Pages 28732-28741, 15(11), 28732–28741. https://doi.org/10.3390/S151128732

Qu, S., Dai, Y., Zhang, D., Li, Q., Chou, T. W., & Lyu, W. (2020). Carbon nanotube film based multifunctional composite materials: An overview. Functional Composites and Structures, 2(2). https://doi.org/10.1088/2631-6331/AB9752

Revolutionising Solar Panels and Touchscreens with Carbon Nanotube Films — Nano Magazine - Latest Nanotechnology News. (n.d.). Retrieved November 4, 2024, from https://nano-magazine.com/news/2024/6/3/revolutionising-solar-panels-and-touchscreens-with-carbon-nanotube-films

Recent Posts

-

Use of Carbon Nanotube in Touch Screen Technologies

Carbon nanotube (CNT)-based transparent electrodes offer flexibility, durability and cost advantages …8th Nov 2024 -

A New Approach to Obesity with Nanotechnology

Obesity stands out as a complex global health crisis that significantly increases the risk of chroni …1st Nov 2024 -

Graphene is the Word in Bionic Technology: EGNITE

Neuroprosthetic technologies have made significant advancements in recent years to enhance the qual …25th Oct 2024