Hydraulic Crimping Machine for Coin Cells - Nanografi Blog

As the demand for more efficient energy storage solutions increases, battery materials such as lithium, nickel, and manganese play a critical role in powering modern devices. Hydraulic crimping machines, specifically designed for coin cell production, ensure the precise and secure assembly of these batteries, enhancing their performance and longevity.

Nanografi, with its wide range of battery materials including high-performance anode and cathode materials, coin cell components, battery foils, and foams, offers innovative solutions to elevate battery efficiency and reliability. Explore Nanografi’s wide range of battery materials to enhance your energy storage capabilities.

Introduction

In the rapidly advancing field of energy storage, coin cells play a crucial role in powering small-scale electronic devices. From research laboratories to commercial applications, ensuring the reliability and performance of these cells is paramount. One key aspect of coin cell production is the crimping process, where precise sealing is essential to prevent electrolyte leakage and ensure long-term functionality. The hydraulic crimping machine is a vital tool designed to meet these requirements. Offering consistent pressure and superior sealing accuracy, this machine enhances the assembly process of coin cells, making it an indispensable asset for both experimental research and industrial production.

What is Hydraulic Crimping Machine?

A hydraulic crimping machine is an industrial tool that joins or secures two components by applying hydraulic pressure. It is typically used to crimp, or fasten, connectors or fittings to hoses, cables, or other materials. By harnessing the power of fluid pressure, the machine generates enough force to make the crimping process quicker, more efficient, and more accurate compared to traditional manual methods.

In essence, the machine applies controlled pressure to reshape and compress materials—whether they are metallic or non-metallic—creating a durable and secure bond between the two parts. This method is especially common in industries such as construction, automotive, and manufacturing, where reliable, leak-proof connections are vital. In the past, crimping required manual labor or electric tools, but modern hydraulic machines have advanced to become more efficient, often running on rechargeable batteries.

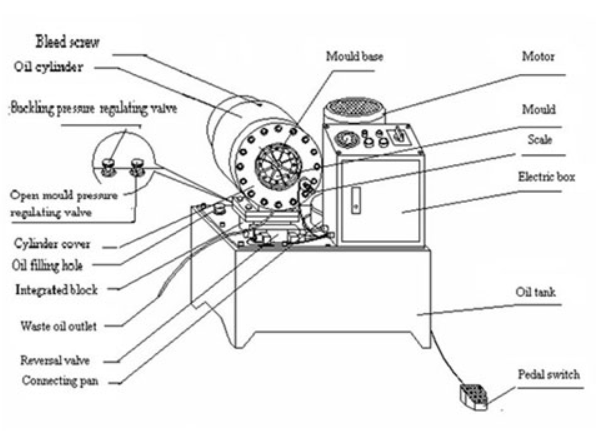

The main components of a hydraulic crimping machine include:

- Hydraulic Pump: Generates the pressure required to crimp the material.

- Crimping Head: The part responsible for applying direct pressure during the process.

- Dies: Interchangeable parts that control the shape and size of the crimp.

These machines range in size, from large models used in industrial applications to smaller, portable versions tailored for specific tasks.

Figure 1. Example of Hydraulic Crimping Machine structure.

Connection to Coin Cell Manufacturing

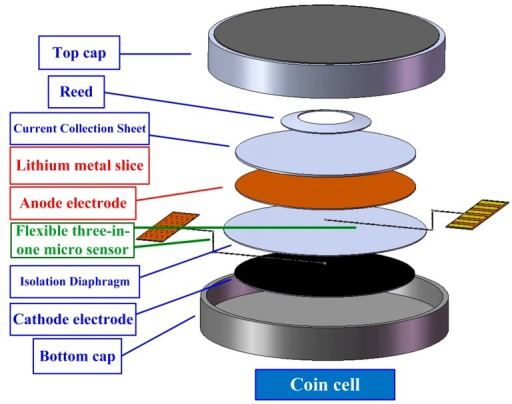

In coin cell production, hydraulic crimping machines are specially adapted to handle smaller, more delicate components. Coin cells, which are tiny batteries often used in electronics, medical devices, and research equipment, require precise crimping to ensure the integrity of their internal components, such as anode, cathode, lithium and other sensitive materials.

For this application, the hydraulic crimping machine is used to seal the two halves of the coin cell together, ensuring an airtight bond that protects the battery's internal structure. Unlike larger industrial machines, those used for coin cells are typically more compact and lightweight, reflecting the lower pressure needed for these small batteries. They also come with precise control features, like adjustable pressure settings, to prevent any damage to the sensitive battery materials during the crimping process.

By using hydraulic pressure, these machines ensure that each coin cell is sealed consistently and securely, which is crucial for the battery’s performance and longevity. This makes hydraulic crimping machines essential in the production of reliable, high-quality coin cells.

Figure 2. Example of a coin cell test assemebly.

How Hydraulic Crimping Machine for Coin Cells Works?

In general, it can be understood that hydraulic crimp machines are used; towards the task of an attachment of a terminal or contact to an electrical conductor. As opposed to a handheld crimp tool, these machines are used in a complete mechanism cycle where the shut heights of the connector ought to be constant. As is evident, these are put to use in an industrial setting, i.e. factories, and production lines (e.g. mechanical engineering field). Traditional crimping tools required both human effort and also brought about significant costs because of the need to employ an electrical force for the pressurization of the tool. Technological advancements have enabled some of these machine systems to merely require rechargeable batteries.

These machines can vary in;

- Physical proportions (i.e. vertical measurement, depth, and breadth)

- Standards-based capacity

- Configuration time and time of the complete cycle. The latter varies in accordance with the hose and fitting styles.

- Tools and dies are marked with color as a means of identification and differentiation.

They are used with the relevant accessories (e.g. hydraulic hose). The hoses are categorized according to;

- Liquid

- Compatibility

- physical force

- intensity of heat

The hydraulic crimping machines used in manufacturing plants and large industries (e.g. construction industry, chemical industry, automobile industry, and petroleum industry) are large and are not ideally moved from one location to another on a regular basis.

In modern times, however, crimping machines used in certain industries, such as for coin cells- have been designed in a more lightweight manner. For example, hydraulic crimp machines used for coin cells have been manufactured in smaller sizes. This may be especially possible because of the lower levels of pressure that can be applied in these machines.

This is run using a number of general steps. Sufficient anti-abrasion hydraulic lubricants ought to be used before ensuring that the electrical source and any other prerequisites cited in the performance manual is fulfilled. The extent of pressure applied is regulated by the operator through the scale. The pressure applied is known as swaging and clockwise/anticlockwise adjustments on the scale will decrease and increase the levels of swaging, respectively. Further regulation of the swaging pressure and pressure in the opening mold can be controlled with the help of (two) knobs at the rear of the oil cylinder. According to the largeness of the rubber hose (on which pressure will be exerted), an appropriate mold (with consideration of both the reference table and the relevant locking pipe and mold) should be mounted on the mold base.

Figure 3. Nanografi's Hydraulic Crimping Machine for All Coin Cells such as CR2016, CR2025, CR2032, CR1220, CR2325.

Applications of Hydraulic Crimping Machine for Coin Cells

The many types of uses of hydraulic crimping machines have been mentioned briefly above. One of the applications of this machine is for the crimping of coin cells. These crimpers are typically able to seal different types of coin cells, which are of varying sizes using different dies. Additionally, the modern crimping machines have special designs that have made the machine much more lightweight and with smaller prints and several other features that ease operations.

The machines are usually sold with die sets. Users also have the option of purchasing additional die sets in other special sized cases according to their preferences. There would mostly be built in gauges in order to monitor and control pressure. The precision of the dies will further contribute to error-free crimping. They also sometimes have a built-in safety valve which can enable the control of pressure limits. This will help alleviate the possibility of damages. On the note of damage, some machines have an anti-corrosion interior and this would prevent the coin cells from getting damaged as a result of short circuits. Some machines also have an aluminum tray that ought to be placed on the base of the crimper and this will help alleviate the possibility of unfortunate oil leakages. These machines can also be utilized for the purpose of disassembly.

The machines usually come with a warranty for up to one year provided that the user does not utilize the machine irresponsibly (e.g. unsuitable storage conditions, insufficient maintenance measures) and cause, for instance; rust. The design of these machines is also is usually equipped with a hydraulic pump that isn’t modeled to hold significant levels of pressure.

Conclusion

As the demand for more efficient and reliable coin cell production continues to grow, hydraulic crimping machines play an essential role in ensuring the high quality and performance of these small but crucial energy storage devices. With precise control over the crimping process, these machines prevent potential failures due to leakage or improper sealing, resulting in longer-lasting and more reliable batteries.

For more insights on battery materials and the latest developments, along with informative contents, visit Blografi.

References

DX68 Hydraulic High Pressure Hose Crimping Machine, Buy Hose Crimping Machine from China Manufacturer - JINBO MARINE. (n.d.). Retrieved September 24, 2024, from https://www.jinbomarine.com/dx68-hydraulic-high-pressure-hose-crimping-machine.html

Hydraulic Crimping Machine for All Coin Cells. (n.d.). Retrieved September 24, 2024, from https://nanografi.com/battery-equipment/hydraulic-crimping-machine-for-all-coin-cells/

Wang, P., Zhang, X., Yang, L., Zhang, X., Yang, M., Chen, H., & Fang, D. (2016). Real-time monitoring of internal temperature evolution of the lithium-ion coin cell battery during the charge and discharge process. Extreme Mechanics Letters, 9, 459–466. https://doi.org/10.1016/J.EML.2016.03.013

Recent Posts

-

A New Approach to Obesity with Nanotechnology

Obesity stands out as a complex global health crisis that significantly increases the risk of chroni …1st Nov 2024 -

Graphene is the Word in Bionic Technology: EGNITE

Neuroprosthetic technologies have made significant advancements in recent years to enhance the qual …25th Oct 2024 -

MXenes from MAX Phases

MXenes, a group of two-dimensional materials derived from MAX phases, are gaining significant tracti …19th Oct 2024