The Role and Benefits of Nanomaterials in Galvanic Coating - Nanografi

Galvanic coating techniques are process used to apply thin layers of metal onto various substrates for purposes like enhancing appearance, improving corrosion resistance, or enhancing conductivity.

Galvanic coating techniques, which involve the deposition of thin metal layers on various substrates for aesthetic, anti-corrosion, or conductivity improvements, can be enhanced by nanomaterials to achieve better coating uniformity, increased adhesion, and improved performance properties. Revolutionary nanomaterials from Nanografi are bridging tomorrow's technology with today. Contact us for more information!

Introduction

Some common galvanic coating methods include electroplating, which uses electricity to deposit metal ions onto a substrate; electroless plating, a chemical process that doesn't require an external current; anodizing, primarily used on aluminum for corrosion resistance; and galvanizing, which applies a zinc layer to protect iron or steel from corrosion. Other techniques include tin plating, gold plating, nickel plating, silver plating, and copper plating, each with specific applications in various industries such as electronics, automotive, aerospace, and jewelry manufacturing. These processes play a vital role in enhancing material properties and extending the lifespan of products.

Understanding Galvanic Coating

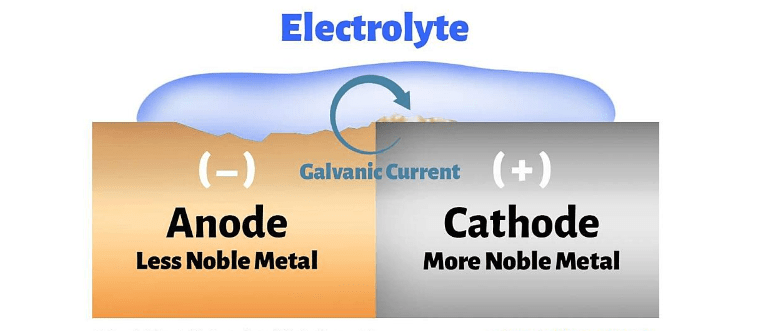

Galvanic coating, also known as electroplating or electrodeposition, is a surface finishing process in which a thin layer of metal is deposited onto the surface of a substrate material. This is achieved by immersing both the substrate (which acts as a cathode) and a metal source (which acts as an anode) into an electrolyte solution and passing an electric current through the system. The metal ions from the anode dissolve in the electrolyte and are then attracted to and deposited onto the substrate, forming a uniform and adherent metal coating.

What is Galvanic Corrosion?

While galvanic coating offers many benefits, it's important to understand the potential for galvanic corrosion, especially when two dissimilar metals come into contact. Galvanic corrosion occurs when two different metals with different electrode potentials are electrically connected and both are exposed to an electrolyte. In the context of galvanic coating, if the plated layer and the underlying substrate have different electrode potentials and are exposed to a conducive environment, the risk of galvanic corrosion increases. This can compromise the integrity and appearance of the coated object. To mitigate this, careful selection of plating materials and appropriate protective measures are essential.

Figure 1. The galvanic process.

Galvanic Coating Process

The galvanic coating process involves depositing a thin layer of metal onto a substrate material. This is achieved by immersing the substrate and a metal source in an electrolyte solution and applying an electric current. The metal ions in the solution are attracted to the substrate, forming a solid metal coating. This process is used across industries to enhance properties like corrosion resistance, appearance, and functionality of various components. It encompasses steps such as cleaning, electrolyte preparation, electrical current application, and quality control, resulting in coated substrates ready for their intended applications.

Properties of Galvanic Coating

Galvanic coatings, also known as electroplated or electrodeposited coatings, encompass a range of properties that make them highly versatile:

Mechanical Properties:

- They enhance hardness, wear resistance, and adhesion, improving durability and strength.

Aesthetic Qualities:

- Galvanic coatings provide smooth, polished surfaces with various colors and luster options, ideal for enhancing aesthetics.

Protective Characteristics:

- These coatings offer corrosion and chemical resistance, safeguarding against environmental factors.

- They can maintain electrical conductivity and biocompatibility in specialized applications.

- Galvanic coatings have a wide array of uses across industries, from enhancing appearance to boosting mechanical properties and providing protection.

Integrating Nanomaterials into Galvanic Coating

Nanomaterials have sparked a significant revolution in coating applications across various industries. These materials, with dimensions below 100 nanometers, offer numerous advantages, including improved mechanical properties, enhanced barrier capabilities, superior adhesion, self-cleaning and anti-fouling properties, heightened thermal stability, optical manipulation, reduced environmental impact, customized functionality, lightweighting, multi-functionality, and innovative uses in paints and architectural coatings. This transformative impact has led to more durable, versatile, and environmentally friendly coatings, with ongoing potential for further advancements in the field.

-Graphene & CNT (Carbon Nanotubes)

Graphene and Carbon Nanotubes (CNTs) are nanomaterials known for enhancing conductivity and strength:

- Excellent Electrical Conductivity.

- Exceptional Strength.

- High Thermal Conductivity.

- Excellent Electrical Conductivity.

- Remarkable Strength.

- Superior Thermal Conductivity.

Both have the potential to revolutionize industries by creating stronger, lighter, and more efficient products, but practical integration is still under development.

-SiC & TiO2 Nanoparticles

Silicon Carbide (SiC) and Titanium Dioxide (TiO2) nanoparticles enhance the conductivity of coatings through distinct mechanisms. SiC improves electrical conductivity and mechanical properties, while TiO2 can contribute to electrical conductivity under UV light and provides UV and corrosion resistance. These nanoparticles offer versatility for customizing coatings to meet specific application needs, particularly when a combination of electrical and other functional properties is required.

-Conductive Carbon Black

Conductive Carbon Black (CCB) is a critical additive in coatings due to its ability to enhance electrical conductivity. Its roles include dissipating static electricity, providing electromagnetic interference (EMI) shielding, guarding against electrostatic discharge (ESD), and even improving corrosion resistance and thermal conductivity. CCB finds applications in various industries and offers customizability in adjusting conductivity levels to meet specific requirements, making it invaluable for applications where electrical or electromagnetic performance is paramount.

To learn the difference between graphene and traditional ceramic coatings, visit our blog page.

Benefits of Using Nanomaterials in Galvanic Coating

The utilization of nanomaterials in galvanic coatings offers a range of benefits, including enhanced corrosion resistance, improved adhesion, increased hardness and wear resistance, superior mechanical properties, thermal stability, electrical conductivity, reduced environmental impact, manipulation of optical properties, self-cleaning and anti-fouling capabilities, and customization to meet specific requirements. These advantages make nanomaterial-infused galvanic coatings highly versatile and valuable across various industries.

Challanges and Considerations in Nanomaterial Integration

Integrating nanomaterials into applications offers significant benefits but also entails various challenges and considerations. These include safety and toxicity concerns, cost implications, scalability issues, stability challenges, uniform dispersion requirements, compatibility concerns, regulatory compliance, and environmental impact assessment. Quality control, intellectual property protection, addressing ethical and societal concerns, education and training, understanding nanomaterial behavior, and conducting thorough risk-benefit analyses are also crucial aspects of nanomaterial integration. Successfully navigating these challenges and considerations requires collaboration among stakeholders and a commitment to responsible and safe nanomaterial use in diverse applications.

Applications of Nanomaterial-Enhanced Galvanic Coatings

Nanomaterial-enhanced galvanic coatings are applied across a wide range of industries for their improved properties. These coatings find applications in aerospace, automotive, electronics, medical devices, energy storage, renewable energy, oil and gas, marine, military, packaging, construction, textiles, sports equipment, electroplating, decorative items, electronics manufacturing, automotive glass, optics, printed electronics, and more. They enhance properties such as corrosion resistance, electrical conductivity, wear resistance, and biocompatibility, contributing to improved performance and durability in various settings.

Future Trends and Developments

Several future trends and developments in nanotechnology were anticipated. These included advancements in nanocomposites, nanomedicine, nanoelectronics, nanophotonics, energy storage, and water purification. Additionally, flexible electronics, nanomaterials in construction, and the use of nanotechnology in space exploration were emerging areas. Ethical, legal, and societal considerations were also growing in importance. Please note that these trends are based on information up to that date, and the field of nanotechnology continues to evolve with new developments and applications. For the latest updates, visit Blografi.

Integrating nanomaterials into galvanic coatings represents a promising avenue for enhancing coating properties and expanding their applications. These nanomaterials, including nanoparticles and carbon nanotubes, offer the potential to significantly improve electrical conductivity, corrosion resistance, mechanical strength, and thermal stability. Their versatility allows for customization, while their multi-functionality reduces the need for complex multi-layer coatings. However, this integration comes with challenges such as safety concerns, scalability, uniform dispersion, compatibility, and regulatory compliance. Despite these challenges, the future prospects for nanomaterial integration in galvanic coatings remain bright, with potential applications in electronics, energy storage, and healthcare. Addressing safety, cost considerations, and adhering to regulations are critical for realizing the full potential of these advanced coatings.

A call to action for further research and exploration in the integration of nanomaterials into galvanic coatings is imperative. Here's why:

1. Unlocking Untapped Potential: Nanomaterials have shown immense promise in improving the performance of galvanic coatings, but there is still much uncharted territory. Exploring the full range of nanomaterial possibilities could lead to groundbreaking discoveries and innovations.

2. Addressing Existing Challenges: Many challenges, such as safety concerns, scalability issues, and regulatory compliance, remain in the integration of nanomaterials. Dedicated research can help overcome these hurdles and make nanomaterial-enhanced coatings more accessible and safe.

3. Industry Applications: There is a growing demand for advanced coatings in various industries, including aerospace,constructionautomotive, and electronics. Further research can provide tailored solutions that meet the specific needs of these sectors. For a comprehensive insight into the applications of nanomaterials in the construction sector, read our blog.

4. Sustainability: Nanomaterials have the potential to contribute to sustainability efforts by reducing material usage and improving the lifespan of coated components. Investigating environmentally friendly nanocoating techniques is crucial.

5. Emerging Technologies: As new technologies and materials emerge, researchers should stay at the forefront to harness their potential for galvanic coatings. This includes developments in nanomaterial synthesis, characterization, and application methods.

In conclusion, further research and exploration in nanomaterial integration within galvanic coatings are critical to harness the full potential of these advanced materials. By addressing challenges, identifying new opportunities, and promoting responsible use, researchers can contribute to the development of coatings that enhance a wide range of industries, benefit society, and promote sustainability. This call to action encourages continued dedication to the advancement of this exciting field.

Conclusion

Integrating nanomaterials into galvanic coatings represents a promising avenue for enhancing coating properties and expanding their applications. These nanomaterials, including nanoparticles and nanotubes, offer the potential to significantly improve electrical conductivity, corrosion resistance, mechanical strength, and thermal stability. Their versatility allows for customization, while their multi-functionality reduces the need for complex multi-layer coatings. However, this integration comes with challenges such as safety concerns, scalability, uniform dispersion, compatibility, and regulatory compliance. Despite these challenges, the future prospects for nanomaterial integration in galvanic coatings remain bright, with potential applications in electronics, energy storage, and healthcare. Addressing safety, cost considerations, and adhering to regulations are critical for realizing the full potential of these advanced coatings.

Discover the high electrical conductivity and resilience of Nanografi's nanomaterials! Elevate the performance and durability of your galvanic coatings, gaining a competitive edge in the industry.

References

Applications of Nanomaterials in the Construction Industry - Nanografi Nano Technology. (n.d.). Retrieved March 14, 2024, from https://nanografi.com/blog/applications-of-nanomaterials-in-the-construction-industry/

Bao, W., Deng, Z., Zhang, S., Ji, Z., & Zhang, H. (2019). Next-generation composite coating system: Nanocoating. Frontiers in Materials, 6, 456324. https://doi.org/10.3389/FMATS.2019.00072/BIBTEX

How Graphene is Better than Ceramic Coatings? - Nanografi Nano Technology. (n.d.). Retrieved March 14, 2024, from https://nanografi.com/blog/how-graphene-is-better-than-ceramic-coatings/

Knitting, Crochet, Jewelry, Beading - Instruction and Inspiration. (n.d.). Retrieved March 14, 2024, from https://www.interweave.com/

The Role and Benefits of Nanomaterials in Galvanic Coating - Nanografi - Nanografi Nano Technology. (n.d.). Retrieved March 14, 2024, from https://nanografi.com/blog/the-role-and-benefits-of-nanomaterials-in-galvanic-coating-nanografi/

Vidales-Herrera, J., & López, I. (2020). Nanomaterials in coatings: an industrial point of view. Handbook of Nanomaterials for Manufacturing Applications, 51–77. https://doi.org/10.1016/B978-0-12-821381-0.00003-X

Recent Posts

-

Turning Noise into Power: Energy Harvesting with Piezoelectric Nanogenerators

Ambient acoustic energy, once an untapped resource, is now being converted into sustainable electric …5th Mar 2025 -

Holey Super Graphene in Li-ion Batteries: Next Generation of Energy Storage

Holey Super Graphene (hG), also referred to as “holey graphene,” is redefining li-ion ba …7th Feb 2025 -

Future Communication with 5G Technology and Advanced Materials

5G technology opens the doors to a new era in communication with faster connection speeds, low laten …6th Feb 2025