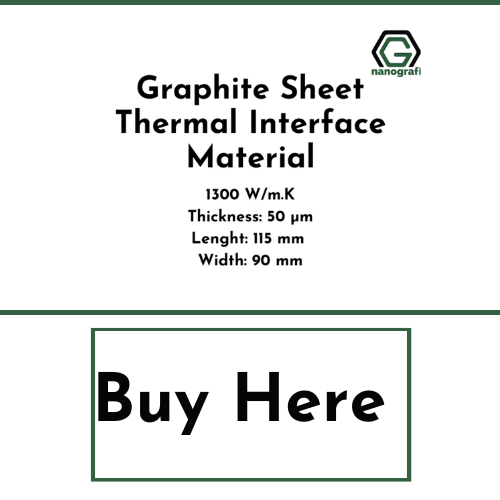

Graphite Sheet as Brilliant Thermal Interface Material

Graphite is one of the crystalline forms of carbon.Its occurrence is natural and due to its excellent properties and characteristics it is used hugely in different areas of science and life itself.

One of its uses in the making of graphite sheet thermal interface material. Due to the excellent graphite properties, thermal interface material with graphite sheet becomes better in its working and is strengthened through it. This helps in better conduction of all the activities that go around the aid of thermal interface materials.

Introduction

Graphite is a good electricity and heat conductor, therefore, making it beneficial in electronic products, for instance, solar panels, batteries, and electrodes. In lubricants and pencils, graphite is utilized. It is also known as the black lead.

History of Graphite

Graphite, also known as plumbago in archaically is carbon's crystalline form having the atoms of carbon arranged in a structure of a hexagon. Naturally, it occurs in this form as under standard conditions, the most stable form is this one. Graphite transforms into a diamond when it is under high temperatures and pressures.

A layered structure, Six carbon atoms rings organized in broadly spaced horizontal sheets, is possessed by the graphite. In comparison with the same element crystallizing in the tetrahedral or octahedral system as the diamond, the graphite crystallizes in the hexagonal system. Usually, these dimorphous pairs have the same physical characteristics but not here.

Graphite is soft, meanwhile, diamond is the hardest substance to naturally occur. Graphite's color is dark gray to black whereas diamond is colorless. Graphite is opaque whereas diamond on the other hand is transparent. Graphite's hardness on the Mohs Scale is 1 1/2. Graphite's name is from 'graphein’, a Greek word, meaning ‘to write’. It leaves behind a black mark and feels greasy.

The metamorphosis of sediments (which contain carbonaceous material) forms graphite by carbon compounds’ reaction with magmatic fluids or hydrothermal solutions, or possibly by magmatic carbon’s crystallization. In carbonaceous clay slates, pegmatites, granites, marble, quartzite, schist, gneiss, and older crystalline rocks, it occurs as veins, large masses, or isolated scales. Cliftonite is the graphitic carbon's small isometric crystals (probable pseudomorphs after diamond) that are seen in meteoritic iron.

Edward G. Acheson accidentally synthesized graphite first when carborundum was being experimented with in high temperatures by him. It's found that in the carborundum, the silicon vaporizes at 7500 F (4150 C) and carbon is left behind in the form of graphite. In 1896, for manufacturing graphite, a patent was granted to Acheson. In 1897, commercial production began. Since 1918, to produce 99 to 99.5 % pure graphite, the significant raw materials are the organic compounds surrounding imperfect and small graphite crystals, and petroleum coke.

Properties of Graphite

The chemical bond type determines the allotropes which are having different forms, for instance, there are various forms of solid carbon. Graphite and diamond are the two most common ones (buckminsterfullerene are the less common ones).

There are sp3 bonds in diamond and tetrahedra is formed by the atoms with each one bound to the four closest neighbors whereas there are sp2 orbital hybrids in graphite and their atoms bounds to the three closest neighbors in planes.

Graphene is the individual layer. The atoms of carbon are organized in each layer in a honeycomb lattice, 0.335 nm is the distance between the planes whereas 0.142 nm is the bond length. There is a covalent bonding between the atoms in the plane. Three potential bonding sites are satisfied out of four. Graphite is electrically conductive as the migration of the fourth electron is free. Due to Van der Waals bonds, in-between the layers, the bonding is weak, allowing the graphite layers to separate with no difficulty and slide past each other. 1000 times lower Electrical conductivity perpendicular to the layers.

Thermal Interface Materials

Now, TIMs are based on adhesives, greases, or polymers which are stuffed with thermally conductive particles, for instance, silica, alumina, or silver, that requires filler’s 50-70 vol % for achieving 1-5 W/mK thermal conductivity values. As candidates, 1 A number of nanomaterials are being investigated to enhance the polymer composite’s thermal conductivity. Due to their high aspect ratio and superior thermal conductivity (∼3,000 W/mK along the tube axis), the carbon nanotubes (CNTs) are an efficient and effective filler.

Graphite Nanoplates

The CNTs cost is inhibiting industrial applications. Here, it's showed that remarkable thermal improvement is provided by the graphite nanoplatelets (GNPs) when it is embedded in an epoxy matrix. GNP is made from exfoliated natural graphite. An industrially viable experiment is demonstrated to process the bull of natural graphite which yields GNPs few layers of similar aspect ratio as of the single-walled carbon nanotubes (SWNTs) but when it is embedded in an epoxy composite, the thermal conductivity increases twice times. An economical pathway is confirmed to next level efficient thermals management materials if these materials are used in applications. A carbon’s allotrope, graphite has superimposed lamellae of 2D carbon-carbon covalent networks, known as graphene, stacking along the c-axis due to very strong van der Waals forces, and separating these layers is a tough challenge.

Graphene's remarkable electronic characteristics led an efficient way to bulk materials, and for studying the single-layer graphene's solution phase characteristics the chemical processing has been employed. They were also employed for preparing individual oxygenated graphene sheets, which were then used to fabricate electrically conductive composites having a very low percolation threshold. For separating the layers of graphene, an alternative route is graphite’s exfoliation. Although, less functional groups in the sheets of graphene promote the material’s reaggregation into the clusters of micron-sized.

To learn more about graphite sheet films, you can read our blog post here.

Nano-mater Sized Graphite Particles

For embedding the graphite particles of nanometer size in the polymer matrices, huge efforts have been done by using a different number of methods and techniques. Improved electrical and thermal conductivities are showed by these composites. Here, the first study is provided on 2D-graphitic filler material’s aspect ratio’s effect on thermal conductivity. The thickness of GNPs is manipulated by the controlled process of dispersion and exfoliation and in this article, this technology’s power is also demonstrated, for achieving an excellent improvement in thermal conductivity of epoxy composites.

For improving the thermal contacts, thermal interface materials are required. For microelectronic cooling, the thermal contacts are specifically important. Dissipation of heat from the source of heat to the heat sink is not adequate in spite of heat sinks of high thermal conductivity. A thermal interface material should be capable of conforming to the proximate surface’s topography because of the reason that thermal contact’s proximate surfaces are never perfectly smooth or flat, thus the air in the surface topography’s valley is displaced.

Categories of Thermal Interface Materials and Use of Graphite

Pastes and solids are the thermal interface material’s two major categories. Solid’s form main benefit is the handling ability. Due to its chemical inertness and resilience, flexible graphite among other solid materials is attractive. The highest thermal contact conductance is provided by these thermal paste-coated metal foils; and mostly, the thermal pads that are based on silicone are utilized in a wide range. The paste form’s main benefit is low interfacial resistivity and low minimum thickness because of the conformability which is stemmed from the nature of the fluid. As compared to other thermal interface pastes, high thermal conductivity is displayed by the silver paste, meanwhile, high conformability is given by the carbon black paste. Exfoliated graphene’s compression makes the material which is known as flexible graphite, made by the intercalated graphite flake’s exfoliation.

Use of Graphite as a Brilliant Thermal Interface Material

Due to exfoliated graphite’s accordion-like microstructure, upon compression, the mechanical interlocking between exfoliated graphite’s pieces (each piece from a worm) happens. In the binder’s absence, the resilient and flexible sheets are formed by the interlocking. Flexible graphite is used to seal the fluid due to its resilience in the direction perpendicular to the sheet as an electromagnetic interference shielding gasket material and as a gasket. Conformability is related to resilience. The flexible graphite can also be utilized as a thermal interface material because of its thermal conductivity and comfortability. Flexible graphite gains attention because of its thermal stability and chemical resistance due to the binder’s absence.

Form of Thermal Interface Materials

Handling is facilitated by thermal interface materials as they are in a standalone sheet's form commonly. Therefore, flexible graphite’s sheet form is more suitable. However, as compared to the thermal pastes, flexible graphite is not as conformable. Thermal paste is carbon black paste as the component of solid and as the vehicle, there is polyol ester oil. Carbon black paste’s high conformability is because of the carbon black solid’s conformability, which is in the form of nanoparticle’s porous agglomerates, enabling the carbon black to capable of being squished. For the spreadability and the conformability, the squish-ability is valuable. Generally, in the case of any thermal interface material, the thermal resistance is determined by the thickness. If the thickness is greater, the thermal resistance will be higher.

As a thermal interface material, flexible graphite is less effective as compared to the carbon black thermal paste because of its high spreadability and conformability. If a thermal paste of carbon black is used to coat both sides of a commercially made flexible graphite sheet, it improves the flexible graphite’s thickness as a thermal interface material. Although, similarly coated aluminum foil is superior to the coated flexible graphite because of the flexible graphite’s large thickness than aluminum foil. Meanwhile, as compared to aluminum foil, the flexible graphite is more effective in the coating’s absence.

Improvement in Performance

The work’s aim is to enhance the flexible-graphite-based thermal interface material’s performance by enabling the penetration of flexible graphite by a thermal paste. Also, the comparison is performed of the effects of paste penetration and paste coating on the performance, and that of the carbon black pastes’ effects with various viscosities and solid contents on the paste-modified flexible graphite’s performance. The article is also focused on understanding the thermal paste’s effect on the flexible graphite’s interfacial thermal resistivity and thermal conductivity, and studying the thickness’ effect and the effect of the fabrication pressure on the flexible-graphite-based thermal interface material’s performance.

Conclusion

There is no doubt about the Excellency of the graphite sheet thermal interface material that is why their production and usage have insanely increased over the past years. They enhance the conductivity and composition of the entire system through these and all in all, these are best for the enhancement of the overall working of the system they are a part of.

To discover the latest news from nanotechnology, you can visit Blografi.

References

Analyzed: Silver Conductive Adhesive Paste - Nanografi Nano Technology. (n.d.). Retrieved April 29, 2024, from https://nanografi.com/blog/analyzed-silver-conductive-adhesive-paste/

Application Areas of Graphene Paste - Nanografi Nano Technology. (n.d.). Retrieved April 29, 2024, from https://nanografi.com/blog/application-areas-of-graphene-paste-/

Carbon Black Properties and Applications - Nanografi Nano Technology. (n.d.). Retrieved April 29, 2024, from https://nanografi.com/blog/carbon-black-properties-and-applications/

Explained Single-Walled Carbon Nanotubes - Nanografi Nano Technology. (n.d.). Retrieved April 29, 2024, from https://nanografi.com/blog/explained-singlewalled-carbon-nanotubes/

Graphene Sheet Films Applications - Nanografi Nano Technology. (n.d.). Retrieved April 29, 2024, from https://nanografi.com/blog/graphene-sheet-films-applications/

Graphite - Wikipedia. (n.d.). Retrieved April 29, 2024, from https://en.wikipedia.org/wiki/Graphite

Graphite Nanoparticles and Nanopowder - Nanografi Nano Technology. (n.d.). Retrieved April 29, 2024, from https://nanografi.com/blog/graphite-nanoparticles-and-nanopowder/

Hu, K., & Chung, D. D. L. (2011). Flexible graphite modified by carbon black paste for use as a thermal interface material. https://doi.org/10.1016/j.carbon.2010.10.058

Yu, A., Ramesh, P., Itkis, M. E., Bekyarova, E., & Haddon, R. C. (2007). Graphite Nanoplatelet-Epoxy Composite Thermal Interface Materials. https://doi.org/10.1021/jp071761s

Recent Posts

-

Turning Noise into Power: Energy Harvesting with Piezoelectric Nanogenerators

Ambient acoustic energy, once an untapped resource, is now being converted into sustainable electric …5th Mar 2025 -

Holey Super Graphene in Li-ion Batteries: Next Generation of Energy Storage

Holey Super Graphene (hG), also referred to as “holey graphene,” is redefining li-ion ba …7th Feb 2025 -

Future Communication with 5G Technology and Advanced Materials

5G technology opens the doors to a new era in communication with faster connection speeds, low laten …6th Feb 2025