Global Cellulose Nanofibers Market and Future

Cellulose nanofibers, also known as CNF are an exceptionally thin form of cellulose fibers that are extracted out from wooden material. The process of forming these cellulose nanofibers is not too tricky but does require constant hard work.

The materials obtained are very lightweight owing to their weight and size which are just a few nanometers. However, on the other hand, their properties and characteristics are very strong which enables them to receive global recognition and due to this their production has seen a massive increase in the global market over the course of past years.

Introduction

The wood material is used to make cellulose nanofibers (CNF) and they are very thin cellulose fibers. The current papermaking technology is also being used for making wood pulp (material that makes paper), and then the wood pulp is micro-refined to the nano-level. It is a new kind of biomass-derived material and it is called nanocellulose at times. The thickness of nanocellulose fibers is close to a few nanometers. They possess strong durability, lightweight, transparency, a different kind of viscosity, and their changes in shape are very little because of the fluctuations in the temperature. There are expectations regarding its usage in various fields.

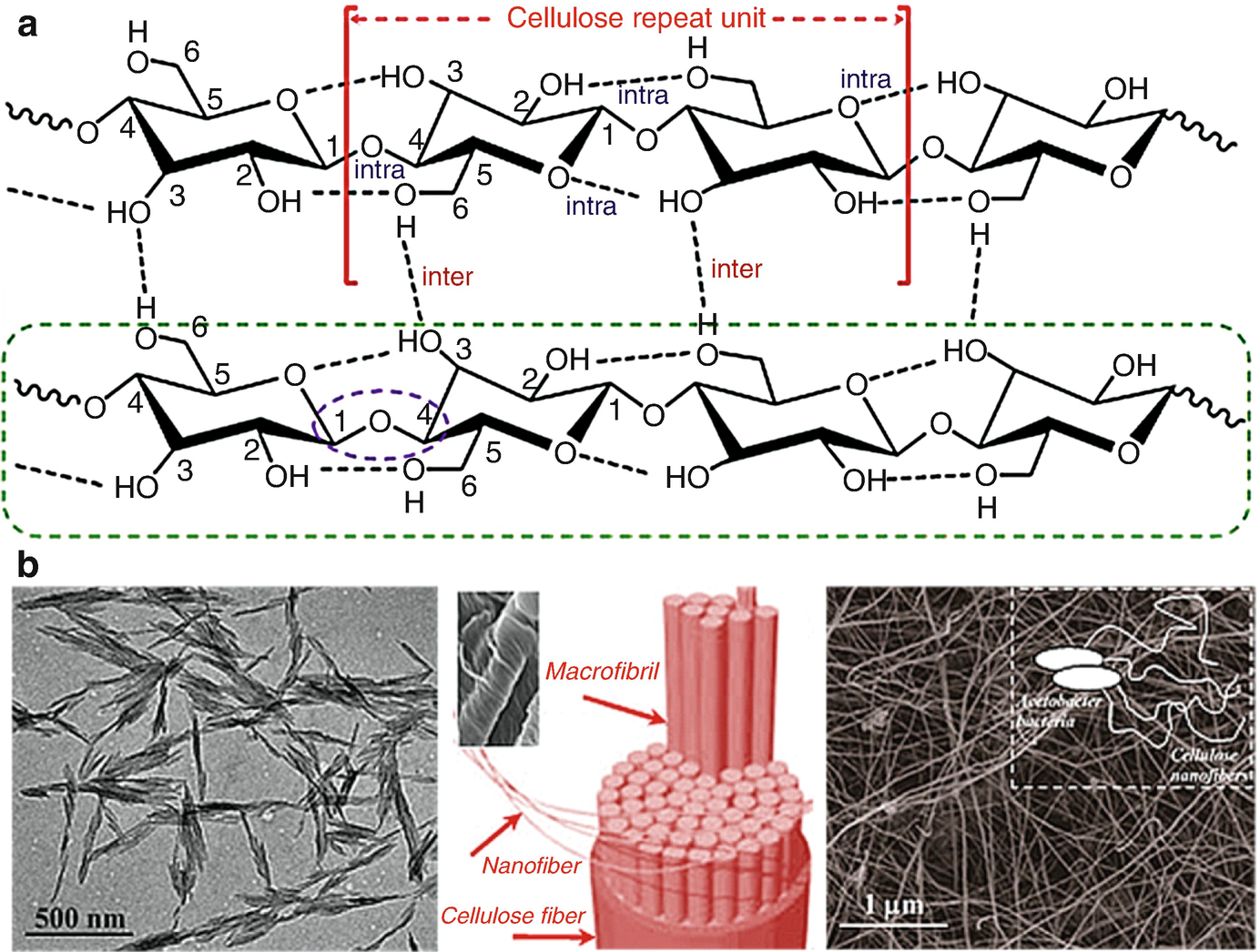

Composition

Having a high aspect ratio (length to width ratio), cellulose nanofiber is a material made up of nanosized cellulose fibrils. 5-20 nanometers is the typical fibril width with a broad number of lengths, usually various micrometers. It is pseudo-plastic. Thixotropy is a characteristic of some fluids or gels and it is displayed by it. When agitated or shaken, they become less viscous but under normal circumstances, they are viscous (thick). Most of its original state is regained by the gel once the shearing forces are removed.

Microfluidization, grinding, or high-temperature, high pressure, and high-velocity impact homogenization is used to isolate the fibrils from any cellulose-containing source for instance, wood-based fibers (pulp fibers).

Source

Acid hydrolysis can be used to obtain nanocellulose fromnative fibers, forming extremely crystalline and rigid nanoparticles that are of 100-100 nm (shorter) as compared to the cellulose nanofibrils (CNF) that are attained by grinding routes, microfluiodization, or homogenization. Cellulose nanocrystal (CNC) is the resulting material’s name.

Manufacture of CNF

Firstly, wood is crushed into woodchips of 1cm thickness and 5cm width. Then there is an extraction of fibers from the woodchips at the paper mill and then pulped. Then there is the chemical processing of the pulp so that it can easily be loosened into thin pieces. Wood fibers (pulp) are then loosened by applying high pressure.

Further processing

There is the chemical processing of the produced pulp (KP) and an ionic compound is added to the wood fiber's cellulose formation. This functional compound's electrostatic repulsive reaction loosens the fiber down to the nano-level easily and breaks it apart stably into thin and long fibers of some nanometers. The fibers are finer as compared to the visible light's wavelength (400-700 nm) and as thin as some nanometers. Thus, as its fibers are permeable to light, it makes the carbon nanofiber transparent.

Mechanical properties

Like Kevlar but better than glass fiber’s, the stiffness of crystalline cellulose is 140–220 GPa. Both glass fiber and Kevlar are commercially used for reinforcing plastics. The high stiffness of 20 GPa and high strength of more than 200 MPa are possessed by the films that are made from nanocellulose but they lack high strain as it is 12%. As compared to stainless steel, its strength/weight ratio is 8 times. Nanocellulose derived from fibers possess high stiffness of 86 GPa and high strength of almost 1.57 GPa.

Barrier properties

The crystalline regions are gas impermeable in semi-crystalline polymers. Nanocellulose can also function as a barrier material because of its comparatively high crystallinity, and with its nanofiber’s capability of forming a dense network that uses strong inter-fibrillar bonds (high cohesive energy density) to stay together. However, there are a limited number of reported oxygen permeability values. Nanocellulose films have high oxygen barrier characteristics according to the reports.

At 0%RH and 23 C, 0.0006 (cm3 µm)/(m2 day kPa) of oxygen permeability was reported for a ca. 5 µm thin nanocellulose film. According to the reports from another study, when a Nanocellulose layer was added to the PLA surface, a more than 790-fold decrease occurs in polylactide (PLA) film’s oxygen permeability.

Influence of nanocellulose

There have been explorations on the effect of the porosity and density of the nanocellulose film on film oxygen permeability. Huge porosity in nanocellulose films is reported by some of the authors and it is in contradiction with high oxygen barrier characteristics, however, according to Aulin et al., the density of the nanocellulose film is near to the crystalline cellulose’s density, referring to an extremely dense film with close to zero porosity.

Changes in surface functionality

Nanocellulose film’s permeability can also be affected by a change in the cellulose nanoparticle’s surface functionality. Negatively charge ion’s permeation can be effectively reduced by the films that are made up of the negatively charged cellulose nanowhiskers, and during this, there will be no virtual effect on the neutral ions. There was an accumulation of the positively charged ions into the membranes.

Hydrogels, colloidal gases, and liquid crystals

Most of the rigid carbon nanocelluloses self-assemble into cholesteric liquid crystals and possess a high excluded volume, due to the surface charge and anisotropic shape of the carbon nano cellulose. Because of the right-handed twist on the particle level, the nanocellulose liquid crystals are left-handed. There is a susceptibility of the nanocellulose phase behavior to ionic charge screening. An increase in ionic strength causes the nanocellulose dispersions to be arrested into the attractive glasses. Nanocelluloses aggregate into hydrogels at a further increase in ionic strength.

If you are interested in CNC Electrodes for fuel cell applications,

you can read our blog post here.

Cellulose Nanofiber Plate (CNFP)

High-performance bulk material of excellent thermal dimensional stability, toughness, high strength, and low density, can be made by using a bottom-up approach. Biosynthesis creates cellulose nanofiber hydrogel. Then surface modification or polymer solution is used to treat the hydrogels and they are then hot-pressed at 80 degrees celsius. Bulk material with remarkable machinability is attained in the result. In CNFP, the ultrafine nanofiber network structure leads to more substantial hydrogen bonding, and high in-plane orientation.

CNFP has high strength because of this structure and by adding barriers to crack formation and propagation and by distributing stress. Delamination can be caused because of the bond between the pressed layers as it is a weak link in this structure. Silicic acid can be used to treat the hydrogel for reducing delamination, and during hot-pressing, it forms strong covalent cross-links between the layers.

Surface modification

A huge amount of attention is currently being gained by nanocellulose’s surface modification. On the surface, a high concentration of hydroxyl groups can be displayed by nanocellulose, which can later be reacted. However, the surface hydroxyl group's reactivity can be strongly affected by hydrogen bonding. Moreover, impurities at nanocellulose’s surface like lignin fragments and glucosidic should be eliminated before the modification of the surface for attaining acceptable reproducibility between various batches.

Global Cellulose Nanofibers Market

Market Drivers

During the forecast period, the cellulose nanofibers market is being driven by the increase in cellulose nanofiber’s usage by the users in research initiatives, healthcare, food packaging, and filters, to develop new carbon nanofibers (CNFs) by prominent players for different applications in different industries. This forecast period is having a lot of growth of the global cellulose nanofibers market as there is an increase in cellulose nanofibers penetration into numerous sectors because of its huge benefits like its ecosystem-friendly nature, high strength, and lightweight, and all of these factors are contributing to its growth.

According to a review

Research is being conducted by the electronics maker Panasonic in May 2017 according to NIKKEI ASIAN REVIEW, on how to use the fiber for making washing machines and refrigerators. In long term, Carbon nanofibers (CNFs) can be a good alternative to steel but they can have major competition from the materials that are produced from the carbon-based materials. The carbon nanofibers (CNFs) can be 5 times stronger and five times lighter than steel according to various researchers.

Industry's key players are searching for steel's alternative as there has been a rapid development in electric cars. In the future, carbon nanofibers (CNFs) can be significantly adopted by the aircraft and automotive industry because of their added benefits.

Market Restraints

As compared to conventional materials, cellulose nanofibers are very expensive which is a major factor that’s being a problem in the global cellulose nanofibers market during the forecast period.

Market Segmentation

Application and product type segments the Global cellulose nanofibers market. Carboxymethyl-cellulose nanofibers, tempo-cellulose nanofibers, and others are included in this product type and its applications include healthcare, electronic devices, cosmetics, food packaging, filters, nanocomposites, and others.

Food packaging

During the forecast period, due to the advantages of cellulose nanofibers, food packaging is currently dominating the global cellulose nanofibers market. Replacements for petroleum-based, environmentally-friendly nature, wax-coated products, metal, glass, and petroleum-based are included in it. This characteristic enables the food to stay fresh for a long time. During traveling when the food is being transported, it enhances its safety and quality.

Similar physical properties

Like PET, cellulose nanofibers have similar physical characteristics and are also a possible replacement to food conservation and packaging due to their capability to offer protection from the carrier substances like antimicrobial and antioxidants.

Geographical Analysis

Division of the global cellulose nanofibers market is in the Middle East and Africa, South America, Asia Pacific, Europe, and North America.

Asia Pacific

During the forecast period, Asia-Pacific dominated the global cellulose nanofibers market because of the presence of paper manufacturers and key players. Paper manufacturers are a significant contributor to the formation of cellulose nanofiber (CNF). Research institutes are increasing the research initiatives to develop novel technology in the cellulose nanofibers field so that they can be used in the automotive industry. That increase is adding to the growth of the Asia-Pacific cellulose nanofibers market.

Japan

The cellulose nanofibers are being increasingly used in Japan in consumer goods, for instance, toilet cleaners, speakers, pens, and disposable diapers.

North America

There are expectations that during the forecast period, North America will gain rapid growth because of the increase in government initiatives to adopt renewable resources and to increase the utilization of carbon nanofibers in numerous applications. According to the U.S Department of Energy, there is a goal that by 2020, 10% of basic chemical building blocks will come from plant-derived renewables, and by 2050, that 10% will further increase to 50%.

Competitive Analysis

The newly launched product, for catering to the demand of the regional market and then the development of a new product, are the key methods that the prominent players adopt in the global cellulose nanofibers market.

July 2018

Rengo Co. Ltd. started using the application of cellophane technology in July 2018 to develop new cellulose nanofiber (Xanthated Cellulose Nanofibers).

September 2017

A cellulose nanofiber mass production facility was launched by Nippon Paper Industries in September 2017, for cosmetics and food at the Gotsu Mill with more than 30 tons of annual production capacity and also made the carboxymethylated carbon nanofiber.

April 2015

There was a collaboration on developing cellulose nanofibers for applications in cosmetics by Nikko Chemicals and Oji Holdings Corporation in April 2015. Daio Paper, Akzonobel, Rettenmaier, Tokushu Tokai Paper Co Ltd, Asahi Kasei, Johnson Healthtech, Cellucomp, Oji holdings, Nippon Paper Group, and GEA group are the main market players in the cellulose nanofibers market.

If you are interested in applications of Li-Ion batteries in automotive,

you can read our blog post here.

Cellulose Nanofiber’s Biomedical Applications

Regeneration and repairing of the tissue is a process of growth, restoration, and renewal, making the function of damaged and diseased tissues, organs, and cells, resilient to natural fluctuations. A particular capability of regenerating and repairing the tissue is possessed by all of the species from bacteria to humans. The effects of substitute implants are different. The individual-self inherently originates the behavior of tissue regeneration and repair for the organism.

Nanocellulose itself has no characteristic of tissue regeneration or repair, but a biocompatible and nontoxic platform can be provided by it for covering growth cells or factors, causing the activation and acceleration of the process of repair and regeneration of the tissue. Healing and regeneration of bone tissue, and skin tissue repair (wound dressings) are the most studied applications of nanocellulose-based biomaterials for tissue healing, regeneration, and repair.

Wound healing and Skin tissue repair

When it comes to skin repair materials (also known as wound dressings), one of their significant property is their capability of absorbing the exudate during the process of dressing and removing it from the surface of the wound after recovery. There are some limitations of gauze and some of the other traditional skin tissue repair materials, for instance, their strong permeability, as it causes the repair materials to have a tight adhesion on the surface of the desiccated wound and therefore on removal, it causes new trauma.

There has been a steady increase in the interest in nanocellulose for the novel wound care due to nanocellulose’s major biological characteristics. A multilayer fermentation method is present, which can be used to fabricate BC skin tissue repair biomaterials. They displayed good proliferation of human adipose-derived stem cells and low cytotoxicity.

Animal experiments

The histological examinations and animal experiments show more fast regeneration of fresh tissue and major formation of capillary in the wound area with BC-based biomaterials. BC's effects as wound dressing material were evaluated in another study on an experiment done on animals, 6 week old male Sprague-Dawley rats, and it confirmed that BC's presence can promote the healing of the wound by accelerating the contractions by accumulating the extracellular matrix.

There are some studies that show the attempts of joining nanocellulose with numerous natural matrices for developing improved biocomposites for potential skin tissue repair materials for instance poly(vinyl alcohol), poly(ethylene glycol), cotton gauze, chitosan, alginate, gelatin, and collagen.

Regeneration and healing of bone tissue

One of the attractive clinical topics for the long term is the development of effective bone regeneration therapy. Around the whole world, periodontal disease, congenital defects, reconstructive surgery, neoplasia, and trauma, causes bone loss.

Nanocellulose and its biocomposites are promising scaffolds for numerous cells, for instance, chondroblast and osteoblast, indicating the potential of the nanocellulose-based materials for regeneration and healing of the bone tissue. Although there are researches on nanocellulose for regeneration and healing of bone tissue, their applications are at the basic stage, and there are only some publications that are reporting the practical effects of animal experiments.

Development of a membrane

Hydroxyapatite and BC made a membrane and it was made a biomaterial for bone regeneration, and it displayed the greater bone nodule formation, high level of alkaline phosphatase activity, and increase in the growth of osteoblast cells. Bone tissue's quick regeneration was expected to be facilitated by the better osteoblasts adhesion, proliferation, and mineralization from BC/hydroxyapatite biomaterials. Then, Saska et al. used in vivo animal experiments to further evaluate the practical effects and biological characteristics of BC hydroxyapatite membranes for bone regeneration.

Outcomes

At 1, 4, and 16 weeks, noncritical bone defects were enhanced in rat tibiae by embedding the biomaterials in them. Like physiological bone, a 1.5 Ca/P molar ratio was displayed by the low crystallinity hydroxyapatite crystals. There were recent reports that were suggesting that there was an introduction of the goat bone apatite in BC to fabricate novel bone repair biomaterials, as they can promote cell differentiation and stimulate the proliferation of the bone cell.

Antimicrobial Nanomaterials

High bacterial levels, particularly the surgical procedures, traumatic injuries, and burn wounds, cause wound infection and it is a major reason for prolonged or delayed healing of the wound. Pathogenic bacteria's adherence and survival on the wound's surface results in concomitant transmission to new hosts, majorly contributing to the pathogen's proliferation, considerably increasing the danger towards human health.

A porous network structure can be provided by nanocellulose in the architecture of biomaterials, and it is advantageous for transferring medicines or antibiotics to the wound while functioning as an effective physical barrier against any external infection. There are also reports that the antimicrobial nanomaterials from nanocellulose display compatibility with biological tissue along with major biodegradability and bioavailability.

The conjunction of antimicrobial agents

Although, chemical or physical approaches are used to generally achieve nanocellulose-based antimicrobial biomaterials by the conjunction of nanocellulose and antimicrobial agents as nanocellulose has no antimicrobial activity itself so it cannot prevent wound infection.

Future of Cellulose Nanofibres

There have been exciting discussions regarding nanocellulose’s diverse biomedical applications, but it is also important to modify nanocellulose before developing practical materials, as that will define its potential biological applications.

Introducing fluorescent molecules

Nanocellulose can be transformed into functional nanoparticles having fluorescent labeling ability by introducing fluorescent molecules on the surface. Fluorescent modification on the nanocellulose allows the nanocellulose to have potential usages in biomedical fields. Fluorescent labeled nanocellulose can be easily traced and they are evaluated for the bioactivity and toxicity in the materials.

Covalent attachments

There have been attempts of covalently attaching diverse fluorescent molecules on CNC’s surface. The fluorescently modified CNC can bring the revolution of the biomedical materials as it is very attractive.

Surface grafting

Biologically active building blocks can be offered by surface grafting of amino acid molecules on nanocellulose, which can add in nanocellulose’s potential of being utilized for DNA delivery as a nanocarrier.

Molecular recognition ability

Recently, there has been a production of DNA-based biocompatible nanomaterials by utilizing the molecular recognition ability of DNA oligomeric base pairs, which are utilized for enzyme/protein immobilization as a special biomaterial. Ferrocene-decorated CNC can be assembled in three-dimensional structures for potential application in biosensors and bioelectrochemical assemblies.

Conclusion

Cellulose nanofibres are an excellent product to carry out various processes in the field of medicine. Their applications are vast in biomedical and so is their production due to the authenticity that they are continuously providing to the fields that they are a part of. All of this is possible due to the high-end properties that cellulose nanofibers exhibit.

To get more information, you can visit Blografi.

References:

https://www.sciencedirect.com/science/article/pii/...

https://www.datamintelligence.com/research-report/...

https://www.marusumi.co.jp/en/paper/cnf/

http://publicationslist.org/data/claudia.som/ref-2...

https://www.jstage.jst.go.jp/article/jos/70/5/70_e...

https://link.springer.com/article/10.1007/s10570-0...

Recent Posts

-

Turning Noise into Power: Energy Harvesting with Piezoelectric Nanogenerators

Ambient acoustic energy, once an untapped resource, is now being converted into sustainable electric …5th Mar 2025 -

Holey Super Graphene in Li-ion Batteries: Next Generation of Energy Storage

Holey Super Graphene (hG), also referred to as “holey graphene,” is redefining li-ion ba …7th Feb 2025 -

Future Communication with 5G Technology and Advanced Materials

5G technology opens the doors to a new era in communication with faster connection speeds, low laten …6th Feb 2025