The Use of Iron Oxide Nanoparticles within Separation Process in the Petroleum Industry

Iron Oxide nanoparticles, often referred to as ferrofluids, have gained prominence due to their unique properties and their ability to enhance the efficiency and effectiveness of various separation techniques.

In this context, separation refers to the process of isolating and purifying different components of crude oil and natural gas, such as hydrocarbons, water, and impurities.The use of Iron Oxide nanoparticles within separation processes in the petroleum industry represents a significant advancement in the field of oil and gas production and refinement.This article will provide an overview of the key aspects and applications of iron oxide nanoparticles in separation within the petroleum industry. Start getting to know Nanografi now, contributing to many studies and industries with its high-performance nanomaterials.

Introduction

The oil extraction industry constantly seeks innovative methods to maximize output from existing reservoirs. Traditional enhanced oil recovery (EOR) techniques often reach a threshold beyond which extracting additional oil becomes economically unfeasible. This challenge has led researchers to explore novel approaches to extend the life of oil fields and improve the efficiency of oil recovery processes. One of them is the use of Iron Oxide nanoparticles in the separation process in the petroleum industry.

What are Iron Oxide Nanoparticles?

Iron Oxide nanoparticles are tiny particles made of iron and oxygen, typically ranging in size from 1 to 100 nanometers. They have unique properties, including superparamagnetism, high surface area, and biocompatibility when appropriately coated. These properties make them valuable in various applications, such as magnetic separation, drug delivery, catalysis, and environmental remediation. Iron oxide nanoparticles are used in fields like nanotechnology, medicine, materials science, and environmental science due to their versatility and beneficial characteristics.

Using of Iron Oxide Nanoparticles for Separation in the Petroleum

Historically, the petroleum industry began with basic distillation techniques in the 19th century. As the industry evolved, more advanced separation methods, including the use of magnetic separation and nanoparticles, were developed to enhance efficiency and address environmental concerns. Today, a combination of traditional and cutting-edge techniques is employed for separation in the petroleum industry.

Iron Oxide nanoparticles, which consist of nanoscale iron particles suspended in a carrier fluid, offer several advantages when used in separation processes. They exhibit superparamagnetic behavior, allowing for precise control and manipulation of the nanoparticles through the application of an external magnetic field. This characteristic enables their effective utilization in various separation techniques, including magnetic separation and oil-water separation.

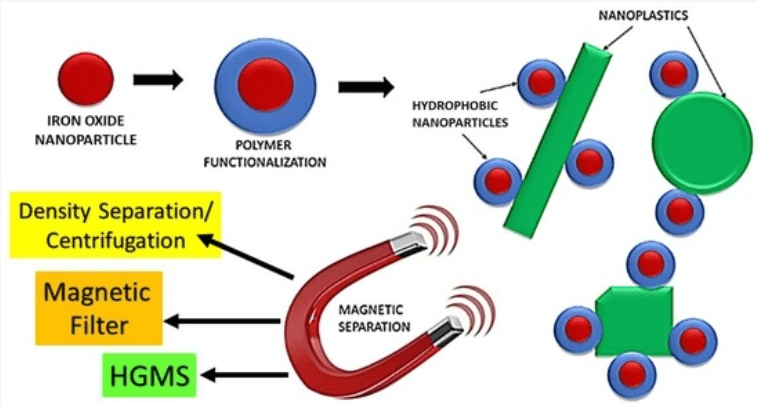

In magnetic separation, iron oxide nanoparticles can be functionalized with specific ligands or coatings to target and selectively bind to certain components in the crude oil, such as heavy metals or organic contaminants. When subjected to a magnetic field, these nanoparticles can be easily separated from the mixture, taking the undesired components with them. This enhances the efficiency of removing impurities and pollutants from the petroleum products, leading to a cleaner and more environmentally friendly end product.

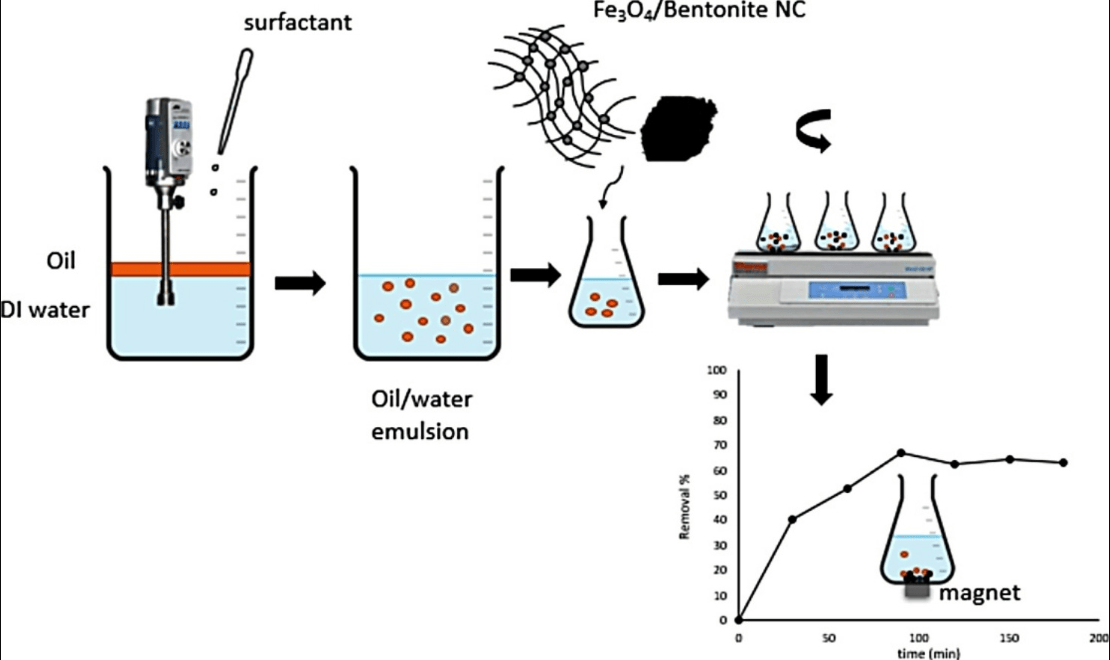

Figure 1. Graphical Abstract of Magnetic Separation

Another critical application of iron oxide nanoparticles is in oil-water separation. Due to their superparamagnetic properties, these nanoparticles can be employed to create advanced filtration systems that efficiently remove water from crude oil. This is particularly valuable in offshore drilling operations, where separating water from oil is essential for transportation and refining. Iron oxide nanoparticles can be incorporated into porous membranes or filter systems, and when a magnetic field is applied, they attract and separate the water, leaving behind the oil, which is crucial for maintaining the quality and economic value of the petroleum products.

Figure 2. Graphical Absract of Oil-water Separation

Mechanism of Iron Oxide Nanoparticle-based Separation

Iron Oxide nanoparticles are used for separation processes in various industries due to their unique properties, particularly their superparamagnetic behavior. The mechanism of iron oxide nanoparticle-based separation involves several key steps:

Functionalization: Iron oxide nanoparticles are often functionalized with specific ligands or coatings to tailor their surface properties. These functional groups enable the nanoparticles to selectively bind to target substances within the mixture to be separated. Functionalization is critical for achieving the desired selectivity in the separation process.

Magnetic Responsiveness: Iron oxide nanoparticles, such as magnetite (Fe3O4), exhibit superparamagnetic behavior. When subjected to an external magnetic field, these nanoparticles become strongly magnetized, aligning themselves with the field. This property is crucial for the separation mechanism as it allows for controlled manipulation and movement of the nanoparticles.

Mixing and Interaction: The functionalized iron oxide nanoparticles are introduced into the mixture to be separated. Through gentle mixing, the nanoparticles come into contact with the target substances, whether they are contaminants, impurities, or specific components of interest, such as hydrocarbons in the petroleum industry.

Magnetic Field Application: An external magnetic field is applied to the mixture. In response to the magnetic field, the superparamagnetic iron oxide nanoparticles align themselves along the magnetic lines of force. This alignment results in the agglomeration or capture of the nanoparticles and the target substances to which they are bound.

Separation: As the nanoparticles and their captured substances become magnetically attracted, they can be separated from the rest of the mixture. This separation can occur in various ways, depending on the specific application. In some cases, a magnetic separator or filter may be used to physically remove the nanoparticle-substance complexes, while in other cases, the magnetic field may direct them to a specific collection point.

Release and Regeneration: Once separated, the magnetic field can be removed, causing the iron oxide nanoparticles to lose their magnetism and release the captured substances. This step allows for the regeneration of the nanoparticles, making them ready for future separation cycles.

Collection of Target Substances: The separated target substances can then be collected and processed according to the particular application. In the petroleum industry, for instance, water can be effectively separated from crude oil, improving the quality and purity of the oil product.

In summary, the mechanism of iron oxide nanoparticle-based separation relies on the functionalization of nanoparticles to selectively bind to target substances, their response to an external magnetic field for aggregation, and subsequent physical separation. This approach offers a precise, efficient, and environmentally friendly means of separating specific components from mixtures, with applications spanning various industries, including petroleum, environmental remediation, and healthcare.

For more information about iron nanoparticles, read our blog post.

Benefits of Using Iron Oxide Nanoparticles for Separation

Using iron oxide nanoparticles for separation provides several benefits:

- Efficiency: Their small size increases contact with substances, improving separation efficiency.

- Magnetic Responsiveness: Superparamagnetic properties aid easy, precise separation with external magnetic fields.

- Selective Targeting: Functionalization allows for specific component isolation, enhancing selectivity.

- Environmental Benefits: Cleaner processes reduce pollution, meeting stringent regulations.

- Oil-Water Separation: Crucial in the petroleum industry, they improve crude oil quality.

- Oil Recovery: Enhance oil recovery rates and extend well lifespans.

- Biomedical Applications: Used in drug delivery and medical imaging.

- Catalytic Activity: Serve as catalysts in chemical reactions for improved yields.

In summary, iron oxide nanoparticles offer enhanced separation efficiency, selectivity, and environmental benefits, making them versatile tools in various industries.

Challenges and Concerns of Using Iron Oxide Nanoparticles for Seperation

Using iron oxide nanoparticles for separation has challenges:

- Cost: Production and functionalization can be expensive.

- Environmental Impact: Concerns about production and disposal.

- Regulatory Compliance: Meeting safety and environmental regulations.

- Scaling Up: Transitioning to industrial scale is complex.

- Safety: Health and safety risks need consideration.

- Contaminant Removal: Complete removal can be challenging.

- Competition: Other separation technologies exist.

Balancing these challenges with the benefits of enhanced separation efficiency is essential for responsible and effective use of iron oxide nanoparticles

Future Prospects and Developments

The future of iron oxide nanoparticle-based separation processes is promising, with several key developments on the horizon:

Advanced Functionalization: Research will enhance specificity in separating substances, benefiting fields like pharmaceuticals.

Customized Nanoparticles: Tailoring nanoparticles for specific tasks will lead to efficient, specialized separations.

Nanoparticle Engineering: Efforts to improve stability and durability will ensure long-term performance.

Scalability: Transition to large-scale industrial applications will continue.

Biomedical Applications: Advancements in drug delivery, cancer therapy, and medical imaging will focus on improving targeting and reducing side effects.

Environmental Remediation: Iron oxide nanoparticles will play a role in cleaning up polluted water and soil.

Energy Production: They may be used in energy materials, such as catalysts for fuel cells and batteries.

Smart Separation Systems: Automation and integration into smart systems will enhance efficiency.

Safety and Regulation: Development of safety standards for responsible use.

Cross-Industry Collaboration: Collaboration between fields will lead to innovative solutions.

Sustainability: Focus on sustainable production and environmentally friendly disposal.

These advancements have the potential to improve efficiency, reduce environmental impact, and find applications in various sectors.

Conclusion

In conclusion, the use of iron oxide nanoparticles in separation processes within the petroleum industry represents a cutting-edge approach with promising benefits. These nanoparticles have diverse applications that enhance efficiency, reduce environmental impact, and contribute to the optimization of petroleum operations. Their role in enhanced oil recovery, water treatment, oil-water separation, and catalytic processes holds great potential for improving resource extraction and refining, all while maintaining a focus on environmental compliance. As technology continues to advance, and research in this field progresses, we can expect even more innovative applications and a continued positive impact on the petroleum industry. The adoption of iron oxide nanoparticles in separation processes aligns with the industry's ongoing pursuit of sustainable and efficient practices.

We,Nanografi, are dedicated to introducing Iron Oxide Nanoparticles, with a commitment to fostering a more sustainable life. Discover our advanced materials and solutions now!

References

Dhingra, M., Yadav, P., Mishra, S., Dwivedi, V., Komal, Ms., Anupriya, Ms., & Sonam, Ms. (2020). Synthesis of Iron Oxide Nanoparticles and its Application for OilWater Separation. Vantage: Journal of Thematic Analysis, 41–46. https://doi.org/10.52253/VJTA.2020.V01I01.05

Iron Nanoparticles: Properties and Applications - Nanografi Nano Technology. (n.d.). Retrieved January 12, 2024, from https://nanografi.com/blog/iron-nanoparticles-properties-and-applications/

Iron Oxide Nanoparticles/Nanopowder and Applications - Nanografi Nano Technology. (n.d.). Retrieved January 12, 2024, from https://nanografi.com/blog/iron-oxide-nanoparticlesnanopowder-and-applications/

Jabbar, K. Q., Barzinjy, A. A., & Hamad, S. M. (2022). Iron oxide nanoparticles: Preparation methods, functions, adsorption and coagulation/flocculation in wastewater treatment. Environmental Nanotechnology, Monitoring & Management, 17, 100661. https://doi.org/10.1016/J.ENMM.2022.100661

Simonsen, G., Strand, M., & Øye, G. (2018). Potential applications of magnetic nanoparticles within separation in the petroleum industry. Journal of Petroleum Science and Engineering, 165, 488–495. https://doi.org/10.1016/J.PETROL.2018.02.048

Recent Posts

-

Turning Noise into Power: Energy Harvesting with Piezoelectric Nanogenerators

Ambient acoustic energy, once an untapped resource, is now being converted into sustainable electric …5th Mar 2025 -

Holey Super Graphene in Li-ion Batteries: Next Generation of Energy Storage

Holey Super Graphene (hG), also referred to as “holey graphene,” is redefining li-ion ba …7th Feb 2025 -

Future Communication with 5G Technology and Advanced Materials

5G technology opens the doors to a new era in communication with faster connection speeds, low laten …6th Feb 2025