Following the Natures Lead: Lotus Effect Self-Cleaning

Lotus effect is a coined term for self-cleaning properties. The excellent water repellency and self-cleaning ability of lotus leaves have inspired the construction of manmade self-cleaning surfaces.

The lotus effect is based on the micro/nano-structures creating roughness on the surface and the hydrophobic wax coating on the lotus leave.These features make it difficult for dirt, dust, and water to adhere to the surface, helping to keep it clean. Such self-cleaning surfaces are utilized in various industries to reduce the need for manual cleaning, thereby lowering maintenance processes nd costs, and offering more sustainable solutions. With the advancements in Nanografi, there are promising opportunities to further enhance these capabilities and design more effective self-cleaning surfaces.

Introduction

Natural systems have been a source of inspiration to the human race for a very long time. Not only they have affected the arts and day-to-day living, but also they have had a significant impact on engineering applications. The sophisticate properties and structures of organisms have been shaped by evolutionary pressure over a long period of time. So, it does make sense to benefit from this evolutionary wisdom while developing novel products and coming up with solutions to complicated problems of engineering. Sometimes, we might even find solutions to the problems we didn’t even know about. Self-cleaning surfaces are an example of this situation. For so long, it was accepted that cleaning required active effort to remove dirt and that surfaces could not clean themselves. However, when it was discovered that plants have “self-cleaning” properties, this conception had to be revised. The leaves of the Lotus plant (Nelumbo Nucifera) have become the face of these self-cleaning properties, so much so that the self-cleaning effect is often claimed as the “Lotus effect”. Lotus plant is considered as a symbol of purity in China for more than 2,000 years since it emerges from swamps and exists in filthy environments but still manages to keep its leaves free of all the dirt around it.

The Mechanism of Lotus Effect

Even though the lotus plant has been a center of attraction for a very long time, the mechanism of the lotus effect has remained a mystery until the invention of scanning electron microscopy. After that, various studies have investigated the lotus effect with the purpose of incorporating this self-cleaning property to man-made products. The self-cleaning effect of lotus leaves is believed to be mainly based on the superhydrophobicity of Lotus leaves. Superhydrophobic surfaces inspired by the lotus effect shows a high static contact angle above 150°, a contact angle hysteresis of less than 10°, low roll-off angles, and low-water holding capacity exhibit extreme water repellence and self-cleaning properties. When water drops fall onto the surface of lotus leaves, they form spherical drops with high contact angles and roll-off from the surface collecting dirt and other particles. Studies on the lotus effect have attributed this hydrophobic behavior to the nanostructure of the lotus leave and epicuticular waxes covered across its surface.

Effect of Nanostructure of Self-Cleaning Properties

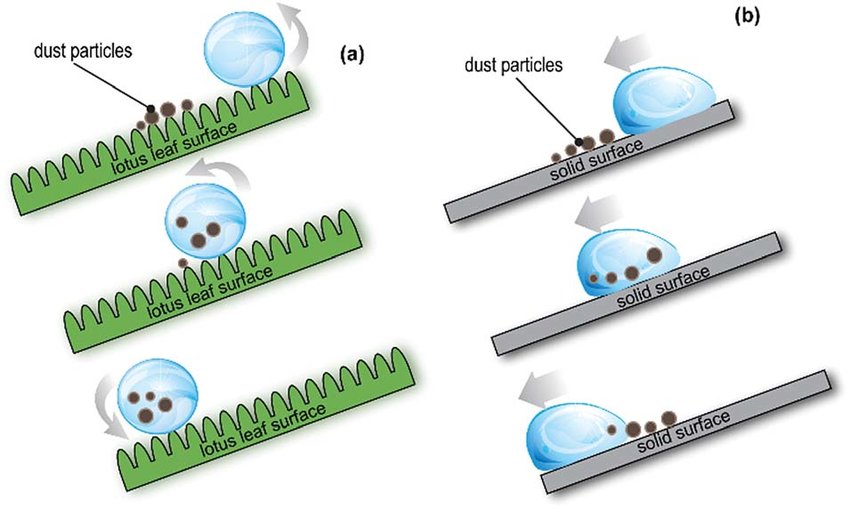

On smooth surfaces, it is not possible to exceed 120° contact angles by means of chemical hydrophobicity. Hence, superhydrophobicity requires surface roughness on nano and micro scales. This surface roughness is perfectly observed on the Lotus leaves with scanning electron microscopy. Lotus leaf surfaces possess randomly distributed micro-papillae with diameters ranging from 5 μm to 9 μm. Additionally, each papilla and the joining surfaces between them contain fine branch-like nanostructures with a diameter of approximately 120 nm. These surfaces are called “low energy surfaces”. The extended nanostructures prevent the underside of the leaf from getting wet while the combination of micro-papillae and Nanosized hair like structures creates pockets of air between the papillae thus, water can interact with only the peaks of the rough surface instead of wetting the entire surface. Air pockets significantly decrease the capillary forces between the droplet and surface. As a consequence, the droplet takes an almost spherical shape and usually rolls off easily. Spherical droplets on rough surfaces hold onto the dirt particles and drag them away instead of rolling over them. This is the result of very low adhesion forces between the dirt particles and the surface of Lotus leaves. When a droplet falls onto the surface, the particle yields to the prevalent capillary forces and adheres to the droplet instead of the surface. Consequently, it is carried away with the rolled off water droplet. Even strongly hydrophobic substances like soot are easily washed off with water only due to the Lotus effect.

Figure 1. Schematic illustration of the "self-cleaning" concept. A water droplet rolling off on (a) a lotus leaf surface and (b) on a smooth solid surface.

Effect of Epicuticular Waxes on Self-Cleaning Properties

All terrestrial plant species are covered with a waxy layer called cuticle which is crucial to prevent uncontrolled water losses from the leaves. Self-cleaning plants have an additional epicuticular wax layer. Epicuticular waxes are self-assembled crystals consist mainly of hydrocarbons, primary and secondary alcohols, and ketones. This additional layer provides hydrophobic properties to the surfaces due to the low surface energy hydrocarbons in their structure. The low energy surface lowers the force that keeps the water in contact with the solid. Only the liquid which has a surface tension equal to or lower than the critical surface tension of a solid can spread on this solid surface. As a result, water droplets form a spherical shape which leads to a lower wet area and lower roll-off angle. The size of wax crystals ranges from 200 nm to 5 μm. On the other hand, the shape of wax crystals has very little importance on the hydrophobic properties.

The Lotus effect relies on both of these parameters, however, the studies have also shown that the desired hydrophobic effect can be achieved through just the surface roughness. It was also demonstrated that it is possible to obtain the superhydrophobic Lotus effect on hydrophilic surfaces by tuning the roughness and morphology of the surface.

The Methods For Imitating The Lotus Leaf Surface

Self-cleaning technology has been inspired by Lotus leaves to develop similar surface structures and self-cleaning properties. Both of the components of the Lotus effect, surface roughness, and low energy surface, hold an important place in developing self-cleaning surfaces. Hence, there are two different approaches to the matter at hand. The self-cleaning surface inspired by the Lotus effect can be obtained by either constructing a micro-/nanocomposite hierarchical structure on an initial hydrophobic surface or modifying the low surface energy materials on the micro-/nanocomposite hierarchical structure surface.

Techniques to fabricate micro/nano-structures on a hydrophobic surface include lithography, etching, anodization, and template replica. Lithography methods which include X-ray, photon, E-beam, and soft lithography have been widely employed for the synthesis of self-cleaning surfaces. Lithography offers precise control of the surface structure allowing the production of surfaces patterned with different shapes and different sizes. Furthermore, the obtained template is easy to be fabricated and can be used many times. Anodization is a metal treatment method in which the surface of a metal and its alloy form an oxide film through the impressed anodic current in the electrolyte solution. The treatment of surface results in random three dimensional shapes creating superhydrophobicity. Another effective method for obtaining micro/nanostructures on the surface is etching. Etching methods include plasma etching, laser etching, and chemical etching. It is a straightforward and effective way of fabricating rough structure surface by etching surface with corrosive gas plasma or laser. By the etching methods, it is possible to obtain a superhydrophobic metallic surface with a content angle of 150°. The etching is a highly selective and rapid method for creating surface roughness however, it has a high cost and not appropriate for large scale applications. The template replica method involves creating a negative template directly from the lotus leave and then creating a copy of the lotus leaf surface by using this negative template. Scientists have created a PVC surface with a 157° contact angle and a 3° roll-off angle showing superhydrophobicity and self-cleaning properties. The template replica method is cost effective, fast, simple, and accurate method of obtaining desired surface roughness for self-cleaning surfaces. This method is also suitable for large scale applications.

To get more information about the lotus effect, you can read our blog post here.

Techniques to fabricate superhydrophobic coatings include sol-gel, dip coating, self-assembly, electrochemical, and chemical/ physical vapor deposition. In the sol-gel method, precursors of chemically active compounds form sols in appropriate solvents and become dry gel after concentrating, aging, and drying. For some materials, nanostructures form after the removal of solvent and result in superhydrophobic and self cleaning properties. The most frequently used materials in the sol-gel method are SiO2, TiO2, and Al2O3. It is possible to obtain alumina gel films with a contact angle of 165° by applying the sol-gel method. This method is simple, low-cost, and applicable on a large scale however, the process takes a long amount of time, result in solvent contamination, and the surface structure is not controllable.

Dip coating is a simple method applied on various different surfaces such as glass, polycarbonate, and poly(methyl methacrylate) (PMMA). The coating materials can be silica, zinc oxide, indium tin oxide, NaCl, and many other materials. Through this simple method, self-cleaning properties are attained by various different materials. The electrochemical deposition has also attracted attention for the production of self-cleaning surfaces. The advantage of electrochemical deposition is its versatility to prepare microscale and nanoscale structures. It is possible to obtain superhydrophobic surfaces with a 173° contact angle through this method. Another widely used method for the preparation of superhydrophobic surfaces is electrostatic spinning. This method offers the preparation of micro-/nanofiber and great control over the morphology through manipulating the ratio and concentration of the spinning solution. Furthermore, electrostatic spinning is a low-cost method that is suitable for large scale applications. Self assembly is a simple and inexpensive method to prepare micro- and nano- dual-scale superhydrophobic surface structures with the self-cleaning property. The self assembly method also provides control over the morphology structures and contact angles over 150°. Chemical/physical vapor (CVD) deposition is a popular method in various different application fields due to its easy process and parameter control. Similarly, it has also attracted attention for the preparation of superhydrophobic self-cleaning surfaces. CVD method includes the deposition of hydrophobic materials such as ZnO and poly(tetrafluoroethylene) (PTFE) onto inherently rough surfaces such as carbon nanotube (CNT) to create superhydrophobic surfaces. The bonding between the substrate and deposited film is significantly strong showing good stability and durability. High contact angles up to 164° are obtained through this method. Even though this method is simple and offers strong substrate-film interactions, the high cost limit it only suitable for the fabrication of some special materials.

Each of these methods is different approaches to the preparation of superhydrophobic self-cleaning surfaces inspired by the Lotus effect. They can be utilized individually or in combination with each other. Hybrid production methods offer great control over the desired parameters and broaden the range of materials used in the production.

Application Areas of Lotus Leaf Inspired Self-Cleaning Surfaces

The understanding of the Lotus effect and development of production methods for self-cleaning surfaces have created a great number of opportunities in various fields. The most significant application areas of the Lotus effect are exterior construction materials, corrosion resistance coatings, textiles, solar cells, sensors, drag reduction, anti-icing coatings, anti-fogging coatings, and anti-reflection coatings.

Exterior Construction Materials

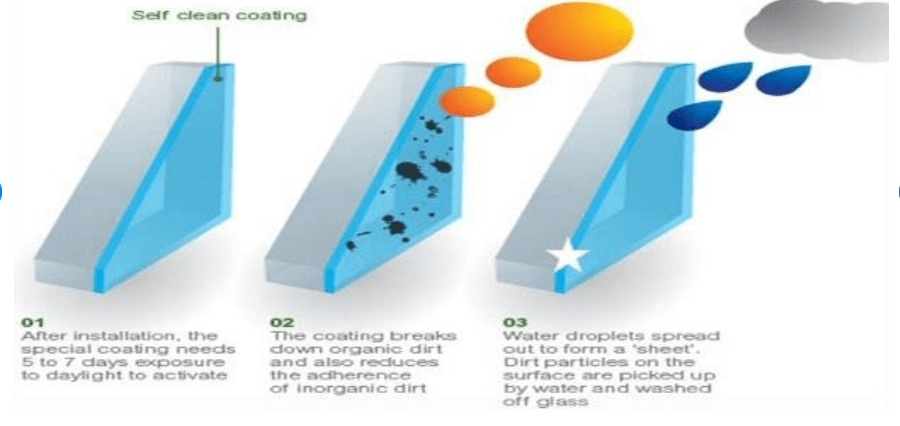

The self-cleaning and water-repellent features of Lotus effect-inspired surfaces are gaining significant attention in exterior construction materials like paints, window glasses, and coatings. These self-cleaning coatings and paints find application on building exteriors to minimize water absorption, mold, mildew, and algae growth. Additionally, due to their strong water repellence, these coatings cause water droplets to roll off, carrying dirt and dust away, thus creating a self-cleaning surface. They are also used on roofs to quickly drain ice melt and rainwater, preventing algae and bacteria formation, and thus enhancing material longevity.

Another application is self-cleaning window coatings, offering not only convenience but also optical clarity since water droplets don't accumulate. In addition to external construction materials, self-cleaning surfaces are used for interior elements like flooring, endowing them with water-repellent properties, bolstering durability and lifespan. Utilizing self-cleaning surfaces helps maintain buildings' visual appeal over time, crucial in urban environments, and substantially reduces maintenance costs.

Lotus effect-inspired self-cleaning coatings are also adopted for pavements, sidewalks, and bridge structures like piers, docks, railings, and dividers, enhancing their service life and water resistance, thus ensuring cleaner and safer environments.

Figure 2. Illustration of self-cleaning window coating.

Corrosion Resistant Coatings

Superhydrophobic coatings have also attracted attention in industrial applications due to their anti-corrosive properties. Metallic surfaces coated with superhydrophobic materials show excellent corrosion resistance hence, improved durability and lifetime. These metallic materials are utilized in the food industry and self-cleaning machine parts.

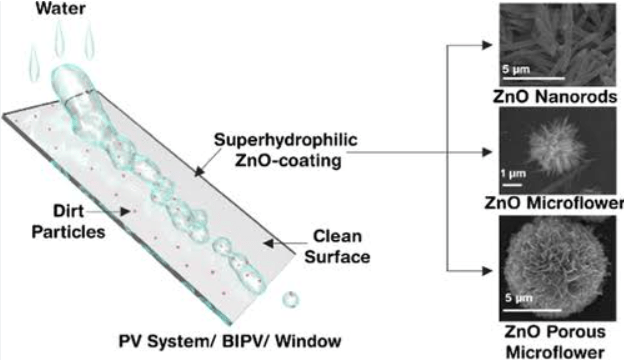

Figure 3. Hydrophilic and Superhydrophilic self-cleaning coatings by morphologically varying ZnO microstructures.

Textiles

The utilization of self-cleaning properties in the textile industry is a no-brainer. Self-cleaning textiles provide convenience, ease of use, and reduction of the use of harsh chemicals such as detergents. Coating fibers with reactive SiO2 nanoparticle monolayers and nonfluorinated polymers creates a self-cleaning surface on the textile which allows the removal of dirt with water and oil-based liquids. This superhydrophobic coating can be permanently anchored to the fiber boundary due to the chemical attachment of the nanoparticles and polymers to the surface. The application of the Lotus effect on textiles provides a range of superhydrophobic self-cleaning products to resist spills, repel and release stains, and resist static.

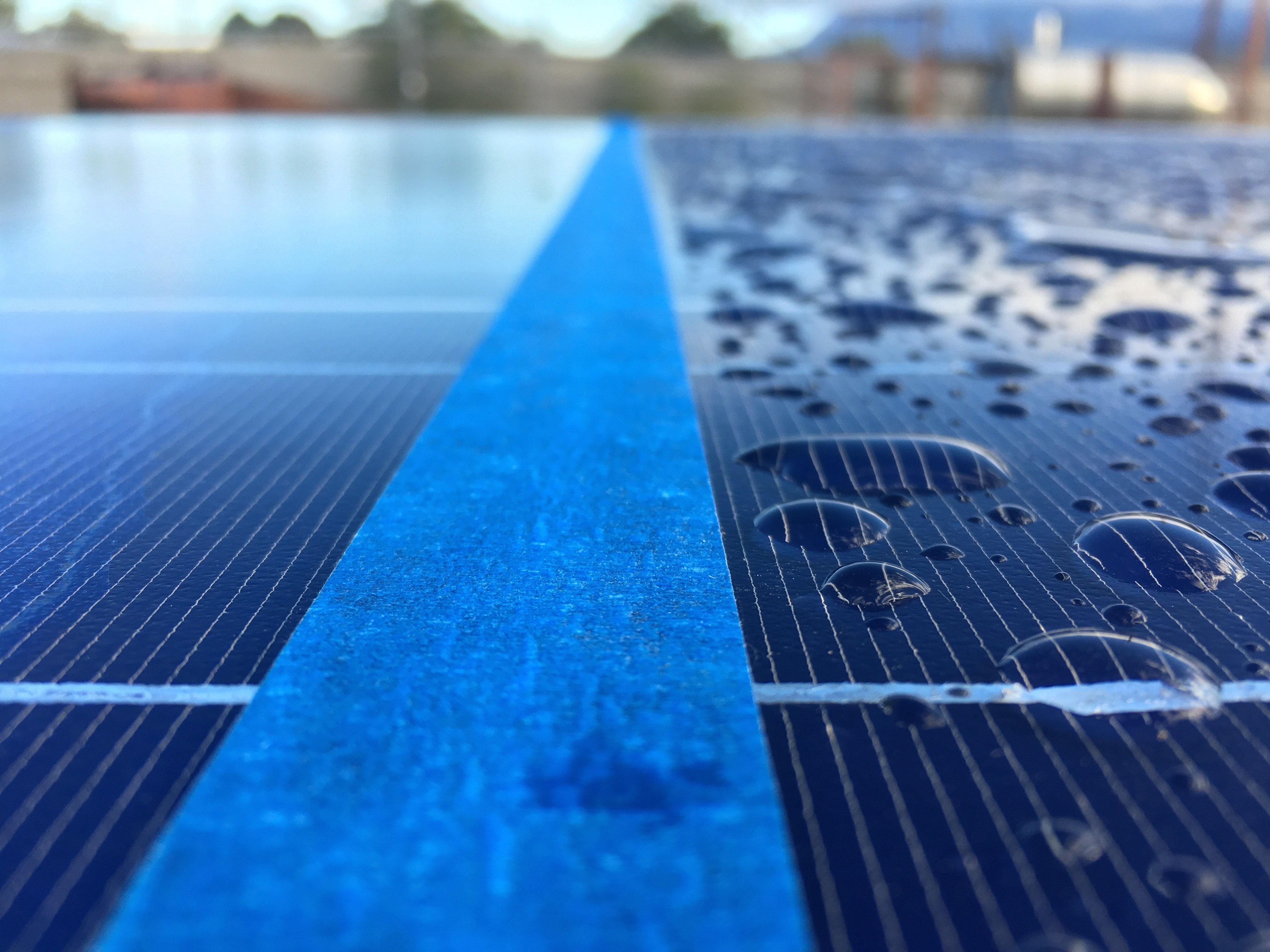

Solar Cells

The superhydrophobic self-cleaning surfaces are greatly utilized in solar cell applications. The water-repellency and dirt removing properties of self-cleaning properties provide transparency and antireflective properties to the organic solar cells. The multifunctional surface results in an enhancement of photovoltaic power conversion efficiency due to the reflection suppression and transmittance enhancement.

Figure 4. Lotus leaf coatings’ anti-soiling coating.

Sensors

Sensors are prone to the accumulation of pollutants and clogging. Especially membranes suffer from clogging and resulted in a decrease in performance. The self-cleaning surfaces inspired by the lotus effect are utilized to eliminate the clogging of membranes by passively and constantly removing dirt and pollutant from the membrane surface. The self-cleaning coatings are also utilized on sensitive infrared nanosensors in bioimaging and optoelectronic devices.

Drag Reduction

Dragging poses a critical problem for the movement of materials. The Lotus leaf inspired materials are found to be drag reducing as well as self-cleaning. The fluidic drag reduction of the superhydrophobic surface is based on the superior water repellency of the surface, which dramatically reduces the interaction on the solid/water interface and generates a thin layer of air to establish a shear-free air/water interface. Based on these observations, the lotus effect can be utilized for the coatings of the underside of ships and other underwater structures.

Anti-Icing and Anti-Fogging Coatings

Fogging frequently occurs on the surface of cold windshields, eyeglasses, safety glasses, and ski goggles due to the accumulation of water molecules on the surface of materials. The incorporation of superhydrophobic coating onto these surfaces inhibits the accumulation, provides anti-fogging and self-cleaning properties. Similarly, icing causes problems such as mechanical failures in cold environments and high altitudes. Even though it is a complex problem, it is possible to aid icing on surfaces by carefully adjusting the effect of wettability, roughness, structure, and morphology of the self-cleaning surfaces.

Conclusion

The phenomenon known as the "lotus effect" or self-cleaning is an impressive manifestation of nature. The superhydrophobic properties of lotus leaves have fascinated scientists and inspired numerous studies. This effect arises from the combination of micro/nano structures on the surface of the lotus leaves and the epicuticular wax coating. The branched structures at the nano level create air gaps between water droplets and the leaf surface, reducing contact area. The epicuticular wax, with its low surface energy, prevents water from making contact with the leaf. The combination of these two properties allows water droplets to take a spherical shape and easily roll off the surface. Thanks to the surface's roughness and hydrophobic nature, dirt and dust particles attach to water droplets, cleaning the surface. For this superhydrophobic property, the water contact angle must be above 150°, and the contact angle hysteresis should be below 10°.

Scientists have developed various methods to mimic this effect and achieve self-cleaning surfaces. These methods aim to either produce surfaces with micro/nano structures or coat rough surfaces with hydrophobic materials. The surfaces obtained have been used in various areas ranging from exterior building materials to window panes, corrosion-resistant coatings to textiles, and solar cells to sensors. However, although research in this field is rapidly increasing, it can be said that there are still many unexplored opportunities in the potential of lotus effect self-cleaning surfaces. To explore and review Nanografi's products featuring the lotus effect and hydrophobic materials, visit website.

References

Anodizing - Wikipedia. (n.d.). Retrieved February 12, 2024, from https://en.wikipedia.org/wiki/Anodizing

Bhushan, B. (2012). Bioinspired structured surfaces. Langmuir, 28(3), 1698-1714.

Cheng, Y. T., Rodak, D. E., Wong, C. A., & Hayden, C. A. (2006). Effects of micro-and nano-structures on the self-cleaning behaviour of lotus leaves. Nanotechnology, 17(5), 1359.

Cuticle: What Is It, Care, Removal, Signs of Infection, and More. (n.d.). Retrieved February 12, 2024, from https://www.healthline.com/health/cuticle

Etching - Wikipedia. (n.d.). Retrieved February 12, 2024, from https://en.wikipedia.org/wiki/Etching

Ganesh, V. A., Raut, H. K., Nair, A. S., & Ramakrishna, S. (2011). A review on self-cleaning coatings. Journal of Materials Chemistry, 21(41), 16304-16322.

Illustration of how self-cleaning glass works, in three steps, from... | Download Scientific Diagram. (n.d.). Retrieved February 12, 2024, from https://www.researchgate.net/figure/Figure-2-8-Illustration-of-how-self-cleaning-glass-works-in-three-steps-from-left-to_fig9_319943282

Lithography - an overview | ScienceDirect Topics. (n.d.). Retrieved February 12, 2024, from https://www.sciencedirect.com/topics/engineering/lithography

Liu, K., & Jiang, L. (2012). Bio-inspired self-cleaning surfaces. Annual Review of Materials Research, 42, 231-263.

Lotus Effect in Nanotechnology - Nanografi Nano Technology. (n.d.). Retrieved February 13, 2024, from https://nanografi.com/blog/lotus-effect-in-nanotechnology/

Nundy, S., Ghosh, A., & Mallick, T. K. (2020). Hydrophilic and Superhydrophilic Self-Cleaning Coatings by Morphologically Varying ZnO Microstructures for Photovoltaic and Glazing Applications. ACS Omega, 5(2), 1033–1039. https://doi.org/10.1021/ACSOMEGA.9B02758/ASSET/IMAGES/LARGE/AO9B02758_0003.JPEG

Safiuddin, M., Hossain, K., & Collins, C. M. POTENTIAL APPLICATIONS OF SELF-CLEANSING NANO LOTUS LEAF BIOMIMICKED COATING IN DIFFERENT CONSTRUCTION SECTORS.

Schematic illustration of the “self-cleaning” concept. A water droplet... | Download Scientific Diagram. (n.d.). Retrieved February 12, 2024, from https://www.researchgate.net/figure/Schematic-illustration-of-the-self-cleaning-concept-A-water-droplet-rolling-off-on-a_fig4_333974770

Solar Anti-Soiling - Lotus Leaf Coatings. (n.d.). Retrieved February 12, 2024, from https://lotusleafcoatings.com/solar-anti-soiling/

Solga, A., Cerman, Z., Striffler, B. F., Spaeth, M., & Barthlott, W. (2007). The dream of staying clean: Lotus and biomimetic surfaces. Bioinspiration & biomimetics, 2(4), S126.

What are superhydrophobic surfaces? (n.d.). Retrieved February 12, 2024, from https://www.biolinscientific.com/blog/what-are-superhydrophobic-surfaces

What is The Lotus Effect in Detail? An Example of SiO2 and Other Hydrophobic Materials - Nanografi Nano Technology. (n.d.). Retrieved February 12, 2024, from https://nanografi.com/blografi/what-is-the-lotus-effect-in-detail-an-example-of-sio2-and-other-hydrophobic-materials/

Zhang, M., Feng, S., Wang, L., & Zheng, Y. (2016). Lotus effect in wetting and self-cleaning. Biotribology, 5, 31-43.

Recent Posts

-

Nanocomposites in Food Packaging

The utilization of nanocomposites in food packaging represents a significant advancement in the fiel …19th Apr 2024 -

What is the Difference Between 7075 and 6061 Aluminum Alloy?

When comparing 7075 aluminum alloy to 6061 aluminum alloy, it's essential to understand their disti …5th Apr 2024 -

Iron-Air Batteries: The Ultimate Guide

Iron-air batteries represent a significant breakthrough in energy storage technology, offering a sus …29th Mar 2024