Examining Nanocellulose: A Promising Approach - Nanografi

Nanocellulose is a plant material made up of cellulose nano-fibers that are broken down into microscopic pieces, then purified and rebuilt. These nano-fibers are composed of elongated tubular cellulose molecules.

Projected advancements in the field of materials science indicate that nanocellulose may soon emerge as a resource that is both cost-effective and durable, in addition to being organic and eco-friendly. In a novel approach, researchers have harnessed a bacterium traditionally associated with the production of coconut cream to transform algae into nanocellulose. This ground-breaking substance harbors the potential to instigate a substantial paradigm shift in our world. Explore Nanografi's nanocellulose products to revolutionize the future of technological infrastructure and secure the well-being of future generations.

Introduction

Nanocellulose is a material obtained by breaking down cellulose, a natural polymer, into nanoscale particles. This material retains the properties of cellulose fibers while exhibiting unique characteristics due to its nanoscale structure. Nano cellulose is known for its high strength, low density, large surface area, and highly crystalline structure.

Nano cellulose has various application areas. Firstly, it is used in the production of nanocomposite materials. By adding nano cellulose into a polymer matrix, it helps improve the mechanical and thermal properties of the material. Additionally, it finds applications in the food industry, such as packaging materials, food additives, and edible films.

Another important application area of nano cellulose is in the production of environmentally friendly materials. This material has biodegradable properties and enables the development of eco-friendly alternatives that can replace plastics. It is also used in the textile industry to produce lightweight and durable fabrics.

In conclusion, nano cellulose is a material with unique physical and chemical properties, and it has the potential for various applications in different industries. Its utilization contributes to the development of environmentally friendly and sustainable material options.

Characterizing Nanocellulose

- It is light, strong and rigid, and with a high coefficient of resistance with respect to its weight (it is eight times more resistant than stainless steel),

- It is stable in terms of temperature changes,

- It has interesting optical properties as it is transparent,

- It dilates little with heat,

- It conducts electricity,

- Since it is a derivative of cellulose, which is a raw material produced by plants in very large quantities every year, it is intrinsically renewable and beneficial for the environment.

Different Types of Nanocellulose

Nanocellulose can be classified into different types based on its characteristics and sources. Generally, nanocellulose can be categorized into three main types: nanocrystalline cellulose (NCC), microcrystalline cellulose (MCC), and bacterial cellulose (BC)

- Nanocrystalline Cellulose (NCC): NCC is obtained by chemically breaking down natural cellulose fibers while preserving their crystalline structures. NCC consists of nanosized crystal particles, typically ranging from 5 to 20 nanometers. It is commonly used to enhance the mechanical and thermal properties of materials by incorporating it into polymer matrices. NCC also shows potential applications in coatings, composite materials, and advanced technology applications.

- Microcrystalline Cellulose (MCC): MCC is produced by mechanically or enzymatically breaking down natural cellulose fibers. It has larger dimensions compared to NCC, typically in the range of 100 to 300 nanometers. MCC exhibits high viscosity, crystalline structure, and a large surface area. It finds applications in the food industry, pharmaceutical applications, paper production, and as a reinforcing component in various materials.

- Bacterial Cellulose (BC): BC is a special type of nanocellulose produced by certain acidic bacteria, such as Gluconacetobacter xylinus or Komagataeibacter xylinus. BC possesses high purity, crystal structure, flexibility, and water absorption capacity. It is utilized in biomedical applications, the food industry, and material reinforcement.

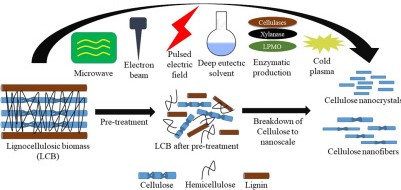

Production Methods for Nanocellulose

Nanocellulose, a versatile and sustainable nanomaterial, has gained significant attention in various industries due to its remarkable mechanical, optical, and barrier properties. Derived from cellulose, the most abundant biopolymer on Earth, nanocellulose offers immense potential for applications in fields such as medicine, electronics, packaging, and textiles.

Mechanical methods involve physically breaking down cellulose fibers to obtain nanocellulose. These techniques include high-pressure homogenization, microfluidization, and grinding. In high-pressure homogenization, cellulose fibers are subjected to intense shear forces and cavitation, resulting in the production of nanoscale cellulose particles. Microfluidization utilizes a similar principle, where cellulose fibers are forced through narrow channels at high velocities, leading to their disintegration into nanocellulose. Grinding techniques involve the use of mechanical forces to reduce cellulose fibers to the nanoscale. Although these methods are relatively simple, they often require large amounts of energy and may cause damage to the cellulose structure.

Chemical methods involve the modification of cellulose fibers through chemical reactions to produce nanocellulose. One commonly used technique is acid hydrolysis, where cellulose fibers are treated with strong acids, such as sulfuric acid or hydrochloric acid, to break them down into nanocellulose. Another approach is the oxidative method, which utilizes powerful oxidizing agents like sodium hypochlorite or 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) to selectively degrade cellulose and yield nanocellulose. Chemical methods offer precise control over the size and properties of nanocellulose, but they can be environmentally unfriendly due to the use of harsh chemicals and require extensive purification steps.

Enzymatic methods employ enzymes, such as cellulases, to selectively degrade cellulose fibers into nanocellulose. These enzymes target specific linkages in cellulose, resulting in controlled disintegration of the fibers. Enzymatic methods are considered more environmentally friendly compared to chemical approaches since they operate under mild reaction conditions and do not produce harmful byproducts. However, they can be slower and require optimization to achieve high yields and cost-effective production.

Figure 1. Emerging technologies in Nanocellulose production.

Bacterial and Fungal Methods: Bacteria and fungi can also be utilized to produce nanocellulose through fermentation processes. Certain bacteria, such as Gluconacetobacter xylinus, have the ability to secrete cellulose nanofibrils, forming a gel-like matrix known as a bacterial cellulose. This method offers advantages such as high purity and control over the nanocellulose structure. Similarly, certain fungi, like Trichoderma reesei, can produce nanocellulose through the action of cellulose-degrading enzymes. Bacterial and fungal methods provide opportunities for large-scale production, but optimization of fermentation conditions and downstream processing are crucial for commercial viability.

Nanocellulose from Agricultural Waste: A promising approach to nanocellulose production involves utilizing agricultural waste, such as rice straw, sugarcane bagasse, or wood chips, as the raw material. By employing techniques like acid hydrolysis or enzymatic treatment, nanocellulose can be extracted from these abundant and renewable sources, reducing reliance on traditional cellulose feedstocks and minimizing environmental impact. This approach aligns with the principles of the circular economy.

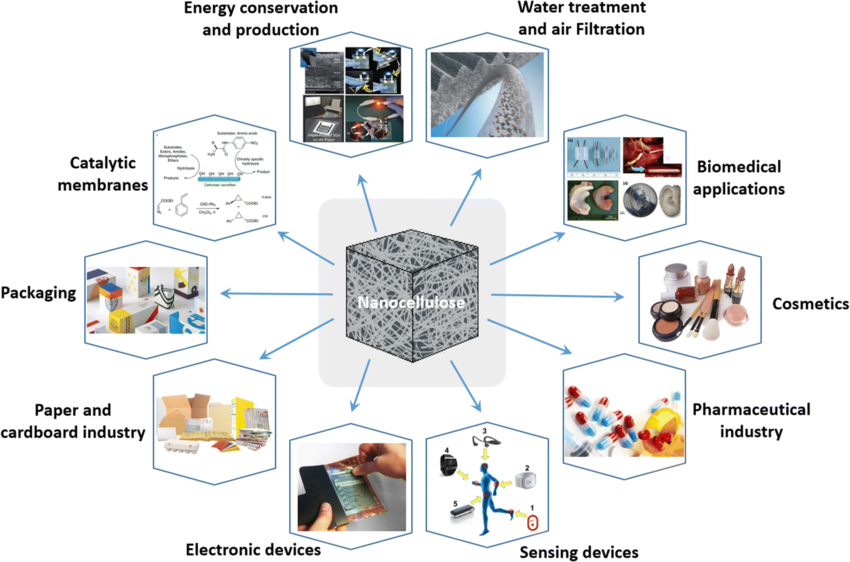

Potential Applications of Nanocellulose

Nanocellulose has great potential for the future. It serves to generate a sustainable biofuel. It can be a solution to the current fuel crisis.

By combining nanocellulose with other materials such as graphene, incredible results can be obtained as batteries that are recharged by just bending them. The possibilities are endless. The more experiments are done with it, the more applications will be found. The prominent applications of Nano cellulose are given below:

1. Lightweight and super resistant reinforcement

Some of the materials that are normally used for this task, such as carbon fiber or ceramics, tend to make the process much more expensive and alter the polymer because they take away clarity and add some color. The nano-cellulose could overcome both obstacles. In addition, its transparent appearance also gives an advantage in this field, since it is perfect for protecting vehicles or making impact-proof helmets, not to mention the glasses of shops with the highest tendency to suffer robberies.

2. More resistant and efficient cars

According to scientists from the University of Maine, adding only 10% of nano-cellulose to the mixture of any composite material increases the strength of the final substance by up to 70%, something that could benefit the transport sector greatly, and the automobile industry especially. Due to its lightness, this could happen without the increase in the weight of cars, and even the weight can be decreased if the nano-cellulose replaces other heavier materials. In this way, the vehicles would not need to consume more fuel to be more resistant and safe.

The Ford automotive company plans to use nano-cellulose to make parts of the bodywork of their cars, as it would help to lose weight.

3. Medical and health use:

The nanocellulose is highly absorbent, porous and can be molded to different shapes. This makes it perfect for making absorbent products such as gauze, bandages or even tampons. Its biodegradable nature is another advantage for these uses, as well as for use in small implants, such as heart valve replacements, artificial ligaments or joint parts. Its applications in the field of medicine are very promising. By combining small amounts of nano-cellulose with water, very stable hydrogels have formed that share many properties with human tissues, which is giving rise to research on the application of drugs and even tissue and organ engineering.

Discover the applications of Cellulose Nanocrystals in medicine by reading our latest blog post.

4. Sponges to clean spills in the sea

By mixing nanocelluloses with water, hydrogels are obtained, but mixing them with other components, all together form aerogels, which are a kind of sponge, capable of resisting stably in water for more than 60 years. This property can be exploited in other uses such as, to facilitate the cleaning tasks after a polluting spill in the sea water.

5. Improve other materials such as plastics or paper

Nanocellulose is a derivative of cellulose, with which paper and cardboard are manufactured. Adding it to its composition can reinforce the network of fibers that compose them and make them stronger and more resistant. It could become an interesting ingredient for boxes and packaging that must resist outdoors, or that are in contact with fatty materials, for example, preventing them from breaking or spoiling. For its properties, it can also be used to improve the mechanical qualities of some plastics, such as thermoplastic resin or latex, making them more flexible and resistant.

The company Pioneer Electronics has big plans for this new material. As it is light, resistant and transparent, it can replace plastic or glass. Currently, it is experimented to be used in the manufacture of thin and flexible screens.

6. Filters

Due to its particular structure, nano-cellulose can be used to create powerful filters capable of purifying almost any liquid. It has the capacity to produce drinking water from seawater, and it is able to filter the blood during transfusions and even ridding smokers of some harmful chemicals from the cigar.

Explore our blog to learn more about "Cellulose Nanocrystals (CNC), Applications and Properties".

Figure 2. Applications of Nanocellulose.

Conclusion

Nanocellulose is a unique material with exceptional physical and chemical properties, offering various application areas in different industries. Its high strength, low density, large surface area, and crystalline structure make it a versatile material.

Through its transformative power, nano cellulose could radically enhance our technological infrastructure, securing a prosperous and sustainable future. Its unique properties and versatility make it a promising material for sustainable solutions in various industries. With Nanografi, we can harness the power of nano-cellulose to lead the way in innovative and eco-friendly technologies that address global challenges and pave the path towards a more sustainable future.

References

Applications of Cellulose Nanocrystals in Medicine - Nanografi Nano Technology. (n.d.). Retrieved March 5, 2024, from https://nanografi.com/blog/applications-of-cellulose-nanocrystals-in-medicine/

Cellulose Nanocrystals (CNC), Applications and Properties - Nanografi Nano Technology. (n.d.). Retrieved March 5, 2024, from https://nanografi.com/blog/cellulose-nanocrystals-cnc-applications-and-properties/

Conversion Techniques of Cellulose into Biofuel- Cellulosic Biofuel - Nanografi Nano Technology. (n.d.). Retrieved March 5, 2024, from https://nanografi.com/blog/conversion-techniques-of-cellulose-into-biofuel-cellulosic-biofuel/

Hydrolysis - Wikipedia. (n.d.). Retrieved March 5, 2024, from https://en.wikipedia.org/wiki/Hydrolysis#Acidic_hydrolysis

Nanocellulose - Wikipedia. (n.d.). Retrieved March 5, 2024, from https://en.wikipedia.org/wiki/Nanocellulose

Nanocellulose as a Perfect Alternative to Plastics - Nanografi Nano Technology. (n.d.). Retrieved March 5, 2024, from https://nanografi.com/blog/nanocellulose-as-a-perfect-alternative-to-plastics/

Pradhan, D., Jaiswal, A. K., & Jaiswal, S. (2022). Emerging technologies for the production of nanocellulose from lignocellulosic biomass. Carbohydrate Polymers, 285, 119258. https://doi.org/10.1016/J.CARBPOL.2022.119258

Trichoderma reesei - an overview | ScienceDirect Topics. (n.d.). Retrieved March 5, 2024, from https://www.sciencedirect.com/topics/biochemistry-genetics-and-molecular-biology/trichoderma-reesei

Recent Posts

-

Turning Noise into Power: Energy Harvesting with Piezoelectric Nanogenerators

Ambient acoustic energy, once an untapped resource, is now being converted into sustainable electric …5th Mar 2025 -

Holey Super Graphene in Li-ion Batteries: Next Generation of Energy Storage

Holey Super Graphene (hG), also referred to as “holey graphene,” is redefining li-ion ba …7th Feb 2025 -

Future Communication with 5G Technology and Advanced Materials

5G technology opens the doors to a new era in communication with faster connection speeds, low laten …6th Feb 2025