The Power of Portable Electronics: Coin Cell - Nanografi

A coin cell is a round cell-type battery that has a flat shape and is generally small in size. This type of battery, also known as a button cell, is commonly used as a power source in various portable electronic devices, including watches.

It derives its name from its resemblance to a coin in shape. Coin cell batteries come in different diameters and thicknesses, but the most commonly used ones have model numbers like CR2032, CR2025, and CR2016. In addition to being used as power sources for portable electronic devices, coin cell batteries are also utilized in battery manufacturing. As Nanografi, we provide you with superior quality and highly durable advanced battery materials necessary for battery production.

Introduction

A coin cell, also known as a watch battery or button cell, is a small, single-cell battery that has a button-like shape. Typically measuring between 5 to 25 mm in diameter and 1 to 6 mm in height, this button-shaped battery is made with a stainless steel bottom and a positive terminal, while the top cover serves as the negative terminal.

Coin cells are used as power sources for small portable electronic devices such as wristwatches and pocket calculators. Devices that use coin cells are often designed to have a long operating life, providing energy for over a year of continuous use in wristwatches, for example. Coin cells generally have a low self-discharge rate, allowing them to retain their energy for extended periods when not in use. However, devices with higher power consumption, such as hearing aids, may use zinc-air batteries with higher capacity that can dry out within a few weeks when not in use.

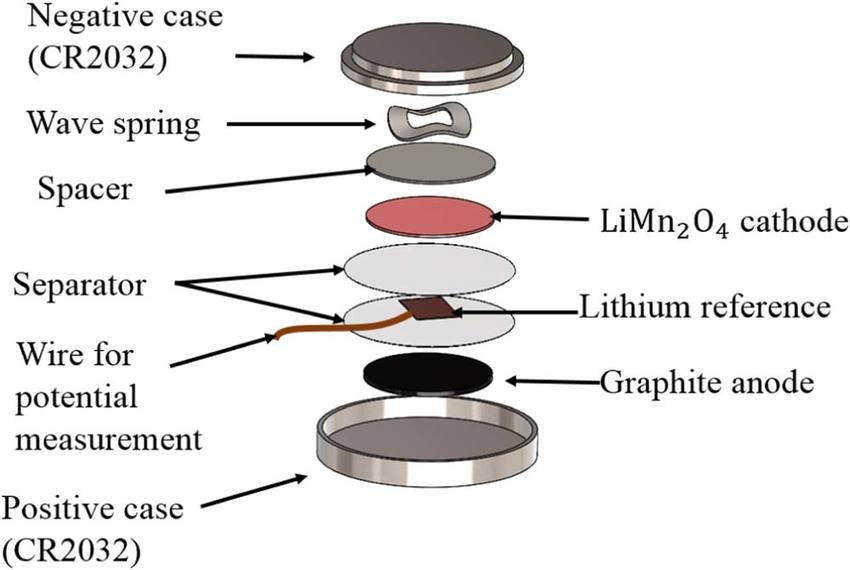

Components of a Coin Cell

Anode: Coin cell anodes are typically made of lithium metal or lithium alloys. Lithium contributes to the release of lithium ions from the anode, which enables the battery to generate energy.

Cathode: The cathode is typically made of a metal oxide compound. Materials such as lithium cobalt oxide (LiCoO2), lithium manganese oxide (LiMn2O4), or lithium iron phosphate (LiFePO4) are commonly used as cathode materials. The cathode accepts lithium ions, allowing the battery to produce energy during discharge.

Electrolyte: The electrolyte is a conductive medium that facilitates the movement of lithium ions from the anode to the cathode. In a coin cell, the electrolyte is usually in liquid or gel form, dissolved in an organic solvent containing lithium salts.

Separator: The separator is a permeable membrane layer located between the anode and cathode. It prevents electron movement while allowing the passage of lithium ions. This helps prevent short circuits within the battery and ensures its safe operation.

Enclosure (Case): A coin cell is housed within an enclosure or case to protect its internal components and provide structural support. Stainless steel or nickel-plated steel is commonly used as the enclosure material.

Sealing Material: Sealing materials are used to protect the internal components of the battery and prevent leakage. The sealing material isolates the internal part of the battery from air and moisture, preventing leaks. Polymer-based sealing materials are widely used.

These components are crucial for the proper and safe operation of a coin cell. During the manufacturing process, these raw materials are carefully selected to ensure the batteries are produced in accordance with quality standards.

How is Coin Cell Produced?

The production of coin cells is a complex process carried out in an industrial environment. Here are the basic stages of coin cell battery manufacturing:

- Preparation: Before starting the production process, the necessary materials and equipment are obtained. Components such as anode, cathode, electrolyte, separator, enclosure materials, and sealing materials are prepared.

- Electrode Manufacturing: Anode and cathode materials are prepared according to predetermined specifications. In this stage, the materials are cut, shaped, and undergo any necessary coating processes.

- Battery Assembly: The prepared electrodes and other components are assembled inside the battery. The separator is placed between the anode and cathode electrodes, and electrolyte is added.

- Sealing: The sealing process is carried out to protect the internal part of the battery and isolate it from external factors. Polymer-based sealing materials are commonly used. This step ensures the internal components of the battery are protected from harmful external influences and minimizes the risk of leakage.

- Testing and Quality Control: The produced batteries undergo testing for performance and quality assessment. Parameters such as capacity, voltage, and current discharge are checked, and tests are conducted to determine the battery's characteristics. Quality control processes are implemented at this stage to identify any production defects or flaws.

- Packaging and Distribution: Tested and quality-approved batteries are appropriately packaged and made ready for distribution. Labeling and packaging processes are carried out, making the batteries market-ready.

Coin cell production requires precise operations, low tolerances, and strict quality control. The manufacturing process is carefully managed to ensure high efficiency, reliability, and compliance with the battery's specifications. Each stage is meticulously monitored, and adherence to industry standards is ensured.

To get more information about how coin cell batteries are produced, you can read our blog.

Coin Cell Features

Longevity: Coin cells offer a long usage life for low-power devices. They can provide energy for years even in standby mode. This reduces the need for frequent battery replacements and provides convenience to users.

Compact Size: Coin cells have small and compact dimensions. This facilitates their use in portable electronic devices and enables devices to be designed lighter and thinner.

High Energy Density: Despite their small size, coin cells have high energy density. This allows the battery to provide long-term usage in portable devices and sustain power for extended periods.

Self-Discharge: Coin cells have self-discharge capability, meaning they can retain their energy for extended periods even when not in use. The energy loss during storage is minimal.

Reliable Performance: Coin cells are known for their stable and reliable performance. Quality control measures are implemented during the manufacturing process, ensuring that the batteries are produced according to high-quality standards. This instills confidence in users.

Various Models: Coin cells are available in different sizes and models. This offers suitable battery options for various devices and provides users with the flexibility to choose the most appropriate one for their needs.

Coin cells provide several benefits to users, including long life, compact size, high energy density, self-discharge capability, reliable performance, and a range of model options. These batteries offer reliable and long-lasting power supply advantages in devices such as watches, remote controls, fitness trackers, electronic toys, calculators, and many more.

Types of Coin Cells

The diameter, thickness, model numbers, and application specifications differentiate coin cells based on specific sizes and requirements, offering suitable battery options for different devices and applications. Here are some common types of coin cells:

CR2032: This is one of the most widely used coin cell types. It has a diameter of 20 mm and a thickness of 3.2 mm. It is commonly used in devices such as watches, remote controls, fitness trackers, and computer motherboards.

CR2025: It has a diameter of 20 mm and a thickness of 2.5 mm. This battery is commonly used in small portable electronic devices and watches.

CR2016: It has a diameter of 20 mm and a thickness of 1.6 mm. This thinner battery is used in devices with slim designs.

CR2450:This battery comes in larger sizes, with a diameter of 24 mm and a thickness of 5 mm. This battery is typically used in devices with higher power requirements.

CR1632: It has a diameter of 16 mm and a thickness of 3.2 mm. This battery is used in watches, calculators, toys, and other portable electronic devices.

These are just a few examples of common coin cell types. There are various other sizes and models available to meet the specific needs of different devices and applications.

Applications of Coin Cells

Coin cells are widely used as a power source in various portable electronic devices. Here are some common applications of coin cells:

Watches: Most analog and digital watches use coin cells. These batteries power the operation of watches and ensure accurate timekeeping.

Remote Controls: Many remote control devices such as TV remotes, game console controllers, and weather stations operate on coin cells.

Fitness Trackers: Fitness bands, smart wristbands, and sports watches rely on coin cells that offer low power consumption and long battery life.

Electronic Toys: Many small electronic toys use coin cells. These batteries provide the energy required for the toys and offer extended usage.

Calculators: Portable calculators operate on coin cells. These batteries power the functions of calculators.

CMOS Memory Backup: CMOS memory on computer motherboards is powered by coin cells. These batteries maintain the computer's date and time settings and preserve BIOS configurations.

Electronic Keys: Some electronic keys and locking systems operate on coin cells. These batteries provide energy with their low power consumption and long life.

Electronic Devices: Portable electronic devices such as thermometers, measuring devices, electronic notebooks, etc., rely on coin cells.

The small size, long lifespan, and low power consumption of coin cells make them an ideal choice for meeting the energy requirements of portable electronic devices.

Conclusion

In conclusion, coin cells play a significant role as power sources for portable electronic devices, offering long life, compact size, and reliable performance. From watches to remote controls, fitness trackers to electronic toys, these batteries are used in a wide range of devices and provide the advantage of long-lasting power with low power consumption.

Nanografi provides production and R&D support to the world's largest technology and industrial companies, universities, and institutes with over 5000 products and an innovative perspective. For more information about our high-quality and advanced technology products, visit our website at: https://nanografi.com/

References

https://en.wikipedia.org/wiki/Button_cell

bit.ly/3Po6LMp

https://www.cpsc.gov/Safety-Education/Safety-Educa...

Recent Posts

-

Nanocomposites in Food Packaging

The utilization of nanocomposites in food packaging represents a significant advancement in the fiel …19th Apr 2024 -

What is the Difference Between 7075 and 6061 Aluminum Alloy?

When comparing 7075 aluminum alloy to 6061 aluminum alloy, it's essential to understand their disti …5th Apr 2024 -

Iron-Air Batteries: The Ultimate Guide

Iron-air batteries represent a significant breakthrough in energy storage technology, offering a sus …29th Mar 2024