Cellulose Nanocrystals (CNC) in Food Industry

Cellulose nanocrystals (CNC) are emerging as a pivotal material in the realm of food technology, heralding a new era of innovation and sustainability. Derived from cellulose, the most abundant natural polymer on Earth, CNC boasts remarkable properties such as biodegradability, high surface area, and impressive mechanical strength.

In the food industry, the application of CNC is becoming increasingly important, not only as a means to enhance product quality and safety but also to address the pressing need for sustainable production practices. Nanografi's CNC products stand as a testament to innovation, providing a sustainable and high-performance solution tailored for the evolving needs of the food industry.

Introduction

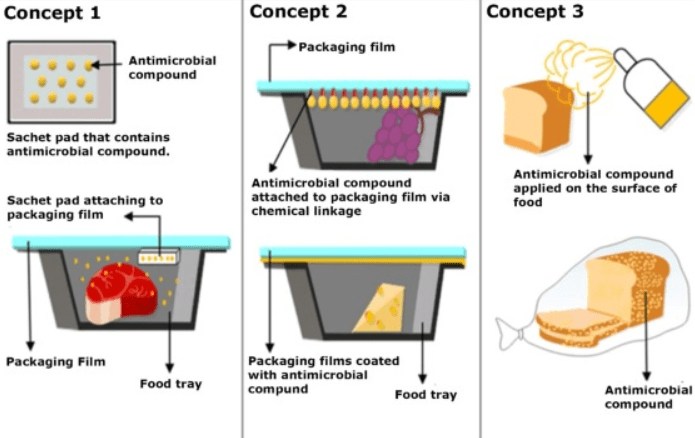

The significance of CNC in the food industry spans across several key areas, including food packaging, additives, and safety measures, contributing to extended shelf life and improved food quality. In food packaging, CNC is utilized to enhance the mechanical and barrier properties of materials, offering solutions that are both sustainable and efficient in protecting food products from spoilage and contamination. As a food additive, CNC's ability to modify texture and stabilize emulsions opens up new possibilities for the formulation of innovative food products. Moreover, the antimicrobial properties of CNC present a promising avenue for enhancing food safety and extending the shelf life of perishable goods, thereby reducing food waste.

What are Cellulose Nanocrystals (CNCs)?

Cellulose nanocrystals (CNC) are derived from cellulose, the most abundant natural polymer on Earth, found in the cell walls of plants. These nanocrystals are obtained through the acid hydrolysis of cellulose fibers, which removes the amorphous regions of the cellulose, leaving behind the highly crystalline portions. CNC exhibits several unique characteristics that make it particularly interesting for various applications, including its biodegradability, high surface area, and remarkable mechanical properties. These nanosized particles have dimensions typically in the range of 5-500 nm in length and 5-70 nm in width, depending on the cellulose source and the extraction process.

The antimicrobial properties of CNC, attributed to the presence of sulfate groups released during the hydrolysis process, have the advantage of significantly reducing food spoilage and waste by inhibiting the growth of certain pathogens and spoilage microorganisms on food surfaces. You can examine its benefits in more detail below.

The Evolution of Cellulose Nanocrystals Use in the Food Industry

Historically, cellulose and its derivatives have been utilized in the food industry primarily as thickeners, stabilizers, and emulsifiers. However, with the advent of nanotechnology, the focus has shifted towards exploring the potential of cellulose at the nanoscale, i.e., cellulose nanocrystals. Recent advancements in CNC technology, including more efficient and environmentally friendly production methods, have paved the way for its application in food production and packaging. Looking forward, CNC is expected to play a crucial role in the development of innovative food products and sustainable packaging solutions, contributing to the overall goal of reducing the environmental footprint of the food industry.

Applications of Cellulose Nanocrystals (CNC) in Food Industry

Cellulose nanocrystals (CNC) are increasingly recognized and used for their potential to improve various properties of food products, such as improving texture, stability and shelf life.

Cellulose Nanocrystal (CNC) in Food Packaging

The application of CNC in food packaging centers around enhancing the functionality and sustainability of packaging materials. Here’s how CNC is making a difference:

Barrier Properties: One of the most critical properties in food packaging is the ability to act as a barrier against oxygen, oil, and water vapor. CNC has shown great potential in improving these barrier properties when incorporated into biopolymer films, which helps in extending the shelf life of food products.

Mechanical Strength: CNC can significantly enhance the mechanical strength of packaging materials. This improvement means that thinner films can be used without compromising the package's integrity, leading to reduced material use and, consequently, less waste.

Biodegradability: Since CNC is derived from natural sources, it is biodegradable. Using CNC in food packaging materials aligns with global efforts to reduce the environmental impact of packaging waste. This feature is particularly appealing in a world striving for sustainability.

Figure 1. Nanocellulose in food packaging.

Cellulose Nanocrystal (CNC) in Food Delivery Systems

Due to CNCs’ biocompatibility, non-toxicity, and impressive mechanical properties, CNCs have garnered interest for use in food delivery systems. These systems aim to encapsulate, protect, and deliver bioactive compounds, such as vitamins, flavors, and probiotics, enhancing food safety, shelf life, and nutritional quality.

Encapsulation of Bioactive Compounds: CNCs can encapsulate bioactive ingredients, protecting them from environmental factors such as oxygen, light, and moisture, which can degrade these compounds. The encapsulation also allows for the controlled release of nutrients, which can improve the bioavailability of compounds that might otherwise be degraded during digestion.

Improvement of Food Texture and Stability: The rheological properties of CNCs make them excellent stabilizers and thickeners in various food products, including yogurts, sauces, and beverages. By improving the viscosity and texture of these products, CNCs can enhance the consumer's sensory experience while also providing stability and reducing syneresis (water separation).

Enhancement of Nutritional Profiles: CNCs can be used to fortify foods with additional nutrients without altering the taste or appearance of the food. For example, CNCs can be loaded with vitamins or minerals and then incorporated into clear beverages, bread, or dairy products, increasing the nutritional value while maintaining product clarity and flavor.

Let's examine it in more detail below:

Cellulose Nanocrystal (CNC) as a Food Additive

The regulatory status of CNC as a food additive varies by region, but it is generally recognized as safe (GRAS) by the United States Food and Drug Administration (FDA) when used in accordance with good manufacturing practices. As a food additive, CNC can offer functional benefits such as texture modification and stability improvement in emulsions and foams. This is attributed to its high surface area and ability to form a percolating network, which can enhance the viscosity and gel strength of food products. Case studies of food products incorporating CNC include its use in low-fat mayonnaise as a stabilizer and in gluten-free bread to improve texture and volume.

Figure 2. Influence of cellulose nanocrystals (CNC) on permeation.

Conclusion

In conclusion, cellulose nanocrystals (CNC) represent a pivotal advancement in the food industry, offering innovative solutions for sustainable food production and packaging. Through its unique properties such as biodegradability, high surface area, and mechanical strength, CNC has emerged as a key material in enhancing the functionality and environmental footprint of food packaging and additives. Its application spans from improving packaging materials to acting as a food additive for texture modification and stability improvement, alongside contributing to food safety and shelf life extension through its antimicrobial properties.

Despite facing challenges in production, integration, and regulatory acceptance, the potential of CNC to revolutionize the food industry remains significant. As we move forward, the continued research and development, alongside collaborative efforts among industry, academia, and regulatory bodies, will be crucial in overcoming these hurdles.

To explore the website of Nanografi, a leader in advanced materials, renowned for its extensive collaborations across more than 100 countries and offering a diverse product range exceeding 4000 items, you can visit their official site directly. This link will guide you to more detailed information about their innovative products and solutions: Visit Nanografi.

Ahankari, S. S., Subhedar, A. R., Bhadauria, S. S., & Dufresne, A. (2021). Nanocellulose in food packaging: A review. Carbohydrate Polymers, 255, 117479. https://doi.org/10.1016/J.CARBPOL.2020.117479

Cellulose Nanocrystals (CNC), Applications and Properties - Nanografi Nano Technology. (n.d.). Retrieved April 30, 2024, from https://nanografi.com/blog/cellulose-nanocrystals-cnc-applications-and-properties/

Fortunati, E., Luzi, F., Puglia, D., Terenzi, A., Vázquez, A., & Torre, L. (2016). Multifunctional bionanocomposite films of poly(lactic acid), cellulose nanocrystals and silver nanoparticles. Carbohydrate Polymers, 147, 243-251. https://doi.org/10.1016/j.carbpol.2016.03.075

Generally Recognized as Safe (GRAS) | FDA. (n.d.). Retrieved April 30, 2024, from https://www.fda.gov/food/food-ingredients-packaging/generally-recognized-safe-gras

Kargarzadeh, H., Ioelovich, M., Ahmad, I., Thomas, S., & Dufresne, A. (2018). Recent developments in nanocellulose-based biodegradable polymers, thermosetting polymers, and their composites for various applications. Polymers, 10(10), 1203. https://doi.org/10.3390/polym10101203

Lin, Y. J., Qin, Z., Paton, C. M., Fox, D. M., & Kong, F. (2021). Influence of cellulose nanocrystals (CNC) on permeation through intestinal monolayer and mucus model in vitro. Carbohydrate Polymers, 263, 117984. https://doi.org/10.1016/J.CARBPOL.2021.117984

Mu, R., Hong, X., Ni, Y., Li, Y., Pang, J., Wang, Q., Xiao, J., & Zheng, Y. (2019). Recent trends and applications of cellulose nanocrystals in food industry. Trends in Food Science & Technology, 93, 136–144. https://doi.org/10.1016/J.TIFS.2019.09.013

Recent Posts

-

Turning Noise into Power: Energy Harvesting with Piezoelectric Nanogenerators

Ambient acoustic energy, once an untapped resource, is now being converted into sustainable electric …5th Mar 2025 -

Holey Super Graphene in Li-ion Batteries: Next Generation of Energy Storage

Holey Super Graphene (hG), also referred to as “holey graphene,” is redefining li-ion ba …7th Feb 2025 -

Future Communication with 5G Technology and Advanced Materials

5G technology opens the doors to a new era in communication with faster connection speeds, low laten …6th Feb 2025