Boron Nitride Nanopowder

Boron Nitride (BN) is a chemical compound which consists of nitrogen and boron. Boron Nitride is of great importance in the nano form because of its unique properties which allow its use in a variety of industries. It has four possible crystalline structures, depending on their hybridization and the stacking of layers. The most versatile and most studied crystal structure is currently the hexagon boron nitride (h-BN) since it belongs to the group of materials called two-dimensional, among which are also the family of dichalcogenides of transition metals such as molybdenum disulfide and graphene. Like the latter material, nanometric objects can also be formed from a sheet of h-BN (2D).

Let’s have a deeper look at different aspects of Boron Nitride:

Types of Boron Nitride

Boron nitride exists under two main varieties.

1. White Graphite boron nitride

The form called BN α or H-BN is of hexagonal structure of graphite type. It is nicknamed "white graphite". It is a very good insulator that has lubricating properties superior to those of high-temperature graphite. Nanoparticles from H-BN can even offer instant cold lubrication and hot thermal stability that increase the mechanical reliability of engine piston-cylinder torques. The H-BN also enjoys a high heat capacity and has a very good thermal conductivity. Refractory and insensitive to thermal shock, it does not get wet by liquid metals or molten glass. It is used for the manufacture of foundry crucibles, measuring probes or coatings for sampling nozzles.

The H-BN can be obtained in various ways, by the reaction between alkaline borates and ammonium salts, between ammonia and boron halides or directly by reduction under high-temperature nitrogen of boron oxide.

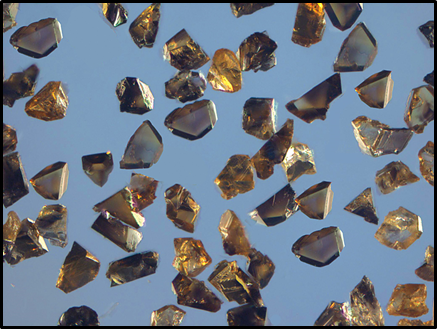

2. Diamond boron nitride

The form called BN β or C-BN is a cubic structure of diamond type. It has an exceptional hardness whose value reaches 60% of that of a diamond. It has thus enjoyed great success as abrasive and super-hard material. Boron nitride is used, for example, to process steel in particular.

It can be produced in the same way as synthetic diamond, under high pressure (62 kbar), at high temperature (1,400 to 2,400 °C), in the presence of catalysts. It is, after the diamond, one of the hardest bodies. It is twice as much as silicon carbide. And it is more heat-stable and is more impact resistant than diamond.

Properties of Boron Nitride Nanopowder

Like graphene, Boron Nitride is also thermally and chemically stable. Its thermal conductivity is 400W/mK, four times lower than that of graphene, but its Young's module is 1.3TPa, higher than graphene, which is 1.1TPa. The length of the bonds in the h-BN is 0.144nm, very similar to the 0.142nm of the graphene. Its link energy is 4eV, also greater than that of graphene, 3.7eV. The spacing between layers is also very similar in both materials: 0.333nm for the case of h-BN and 0.335nm for the case of graphene.

In the same case as in graphene, the bonds between nitrogen and boron atoms of the same layer are very strong σ type bonds, but the links between two layers are Van der Waals type, very weak. The most important difference between both materials is at the level of their electronic properties according to the band theory: while graphene is a conductor, the h-BN is an insulator, since it has an energy of the 6eV gap, which would enable its application in electronic devices if it could be reduced to a maximum of 3.5eV.

Both graphene and h-BN have some similar properties, but the latter is obtained from BN and not from graphite (black), h-BN is often referred to as "white graphene."

Discover all applications of Graphene: 60 Uses of Graphene – The Ultimate Guide to Graphene’s (Potential) Applications in 2019

Production of Boron Nitride

Due to the weak links between layers of BN, it is very easy to separate them and obtain them simply by exfoliating them from a BN crystal. Another possible way to obtain them is from the borazine molecule using the CVD ( Chemical Vapor Deposition ) method, in which the surface on which we want to grow h-BN is heated so that when the molecule strikes it, it ionizes, the bonds with the atoms of H are broken, that will form H2 (very volatile compound), leaving on the surface the rings of N and B that will form the hexagonal network of the BN.

Applications of Boron Nitride Nanopowder

The fullerenes of Boron Nitride have good lubricity, which has led to its use in the cosmetics industry. They also have a good capacity to absorb substances such as hydrogen and organic compounds, which means that they are being investigated whether they would be used to absorb pollution produced in cities.

The nanoparticles of BN improve the thermal conductivity in nanofluids while maintaining its viscosity. It has also been proven effective in inducing apoptosis and inhibiting the proliferation of cancer cells in the prostate.

The nanotubes of BN allow to increase the thermal conductivity and improve the mechanical properties of ceramics and metals. They are also used to absorb hydrogen, to produce field emission and ultraviolet luminescence. They are capable of inducing apatite, very useful for orthopedic applications. Likewise, its effectiveness in transporting DNA and drugs to cancer cells through the bloodstream has been proven when magnetic assistants such as Gadolinium fluoride doped with Europium are used.

The nanocintas of BN have also improved the mechanical properties and chemical stability against the degradation of polymeric compounds and preserved their insulating nature.

The BN monolayers are capable of increasing the mobility of graphene electrons, as well as opening a gap in it, making graphene a semiconductor. They also serve to protect transistors, tunnel devices, and hydrophobic monolayers against oxidation due to their inert character.

The nitride nanoporous boron has applications in absorbing H2 and transport drugs to cancer cells on hydrophilic surfaces. On its surface atoms such as calcium and lithium can be deposited. It is able to absorb organic pollutants.

When BN is deposited on other substrates with hexagonal unit cells of different sizes or with which it forms a certain angle, super-periodicities in the network called Moire patterns are formed, on which they can be deposited in an orderly and controlled manner molecules, atoms or even fullerenes, thus advancing on the road to self-assembled nanometric devices.

The use of Boron nitride nanoparticles for decontamination

Its great power of absorption of chemical substances opens an interesting field for its use in water treatment. Water quality controls for human consumption will be refined in the very short term with the development of biotechnology techniques or the use of nanomaterials to eradicate the polluting elements of industrial or agricultural activity. As an efficient nanomaterial in this regard, the latest research points to the great power of boron nitride discovered at the beginning of the 19th century.

At the moment, the market is reluctant to incorporate new techniques for quality controls and prefers to continue applying traditional chemical and filtering procedures to guarantee water potability, but the lower cost and greater efficiency of the new ones. Remediation materials - whether biological or not - that are investigated in laboratories will eventually impose their standardization.

One of the nanomaterials (having a size less than one micron) that researchers point to as key in the treatment industries is boron nitride.

Use of BN’s Insulating and Highly Waterproof Properties

It is an extremely hard material - the second after the diamond, which allows an application as an abrasive for industrial tools - with electrical insulating properties, waterproof and excellent heat conductor.

These uses are very important due to its great absorption and selection power, it is able to retain up to 33 times its weight, which has led various research groups to analyze their use to remedy water contaminated by chemical substances or waste heavy industrial oils. A method that can be very effective especially for treating water contaminated by uncontrolled spills.

The authors of the research (Weiwei Lei, David Portehault, Dan Liu, Si-Qin, and Ying Chen) have proven the success of this nanomaterial for the removal of oils, organic solvents and dyes dissolved in water. The scientists created porous sheets composed of this material that are capable of retaining large amounts of ethylene glycol inside it - a liquid for industrial use for the manufacturing of automobile antifreeze or for the manufacturing of highly toxic polyester compounds - or for contaminants.

The filter has a great advantage over those built with other types of materials since it can be heated at high temperatures or burned to recover its absorption capacity.

Other Uses of Boron Nitride Nanopowder

It is not only the future use of boron nitride nanoparticles. Other lines of applied research pursue its use to create a type of plastic container to increase the shelf life of bottled beer.

Its insulating capacity and its high degree of impermeability can prevent two key elements in the taste of beer from being lost over time. The new material based on boron nitride would prevent oxygen from entering the bottle and carbon dioxide from escaping, allowing the flavor and effervescence to last longer in its bottling period.

However, researchers are facing preliminary investigations, since they will have to carry out other studies to unravel whether nanomaterials or biomaterials will be a real alternative in the short term to replace current water decontamination techniques. This type of study does not evaluate the variable of its potentialities in absorption as a fundamental element but rather the cost/product ratio and the ability to apply them on a large scale. The market is governed by the law of obtaining the benefit.

Some other applications of Boron Nitride Nanoparticles are:

- Protection and sheath for thermocouple and measuring probe

- Protection for casting tools

- Electrical insulation at very high temperature

- Crucible for foundry and sintering

- Resistance support

- Solar and photovoltaic industry

- Oven structure: tube and insulation sleeve

- Soldering and soldering: nozzle, soldering support

- PVD installations: masking support, coating support

As we saw, Boron nitride Nanopowder is very valuable in terms of its use for different purposes. It has exceptional temperature resistance, dielectric strength, and thermal conductivity. Thanks to these different properties, boron nitride is an easily machinable material. Boron nitride is comparable to graphite for its lubrication properties and its good thermal conduction, but on the other hand, it is white and has very good electrical insulation capabilities. In addition, it does not wet by most molten metals and slags and can, therefore, be used as a container for most molten metals, including aluminum, sodium, iron, steel, silicon, boron and copper. Moreover, its use in water treatment is also of great importance.

Recent Posts

-

Nanocomposites in Food Packaging

The utilization of nanocomposites in food packaging represents a significant advancement in the fiel …19th Apr 2024 -

What is the Difference Between 7075 and 6061 Aluminum Alloy?

When comparing 7075 aluminum alloy to 6061 aluminum alloy, it's essential to understand their disti …5th Apr 2024 -

Iron-Air Batteries: The Ultimate Guide

Iron-air batteries represent a significant breakthrough in energy storage technology, offering a sus …29th Mar 2024